Suzuki Grand Vitara JB416 / JB420. Manual - part 113

1D-120 Engine Mechanical: For J20 Engine

Main Bearings, Crankshaft and Cylinder Block

Removal and Installation

S5JB0A1426041

Removal

1) Remove engine assembly from vehicle. Refer to

“Engine Assembly Removal and Installation: For J20

Engine”.

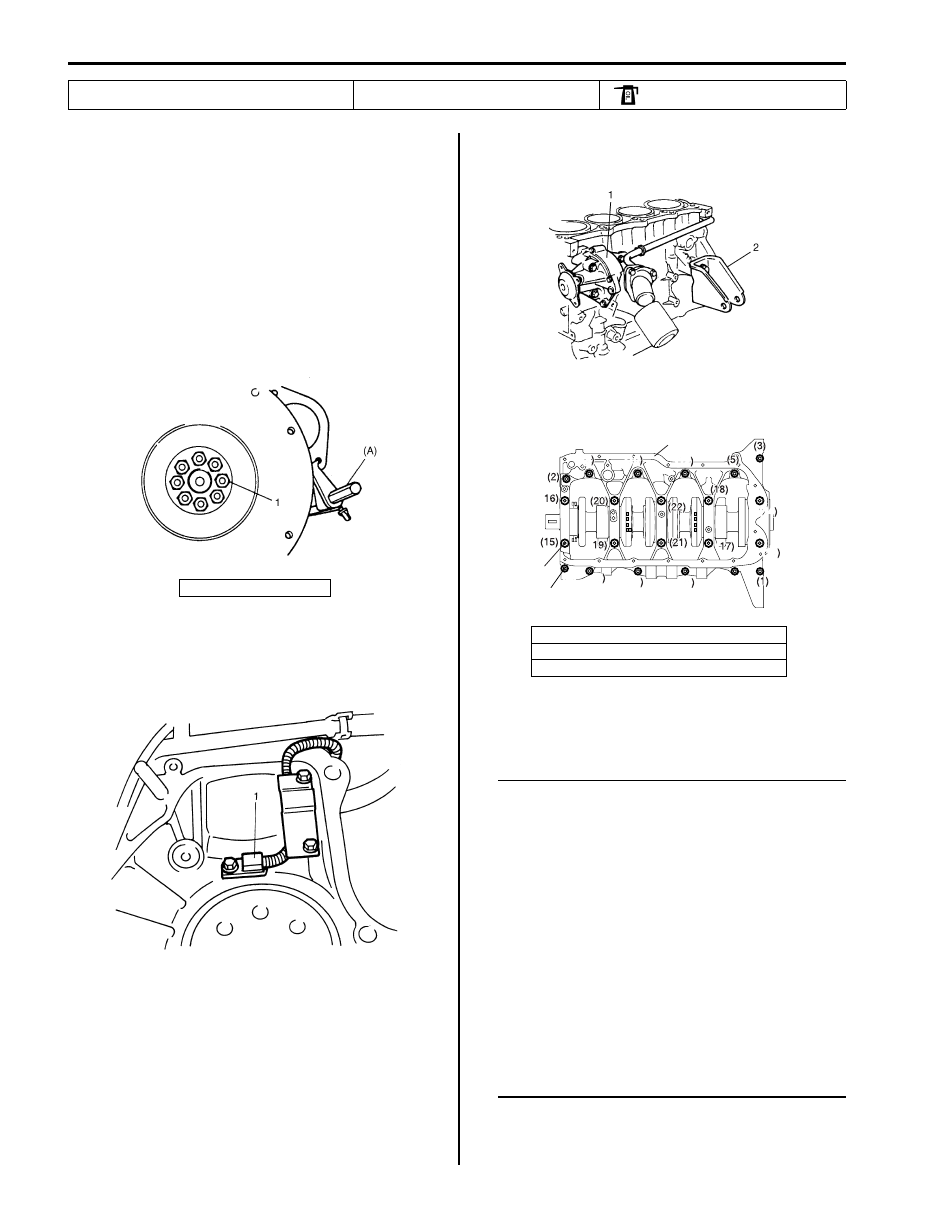

2) Remove clutch and flywheel (drive plate for A/T) by

using special tool.

Special tool

(A): 09924–17810

3) Remove pistons and connecting rods referring to

“Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation: For J20 Engine”.

4) Remove CKP sensor (1).

5) Remove water pump (1) and heater outlet pipe.

6) Remove engine front mounting brackets (2).

7) Loosen crankcase bolts, in sequence shown in figure

and remove them.

8) Remove crankshaft from cylinder block.

Installation

NOTE

• All parts to be installed must be perfectly

clean.

• Be sure to oil crankshaft journals, journal

bearings, thrust bearings, crankpins,

connecting rod bearings, pistons, piston

rings and cylinder bores.

• Journal bearings, crankcase (bearings

caps), connecting rods, rod bearings, rod

bearing caps, pistons and piston rings are

in combination sets. Do not disturb

combination and try to see that each part

goes back to where it came from, when

installing.

• Clean mating surface of cylinder block and

lower crankcase, remove oil, old sealant

and dust from mating surface.

8. Rear oil seal

16. Flywheel mounting bolt

: Apply engine oil to inside / sliding

surface.

1. Flywheel bolt

I2RH01140169-01

I2RH01140170-01

1. Lower crankcase

2. Crankcase bolts (10 mm thread diameter)

3. Crankcase bolts (8 mm thread diameter)

I2RH01140171-01

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(17)

(18)

(19)

(20)

(21)

(22)

1

2

3

I4RH01140045-01