Suzuki Grand Vitara JB416 / JB420. Manual - part 101

1D-72 Engine Mechanical: For J20 Engine

Valve Lash (Clearance) Inspection

S5JB0A1424003

1) Remove negative cable at battery.

2) Remove cylinder head cover referring to “Cylinder

Head Cover Removal and Installation: For J20

Engine”.

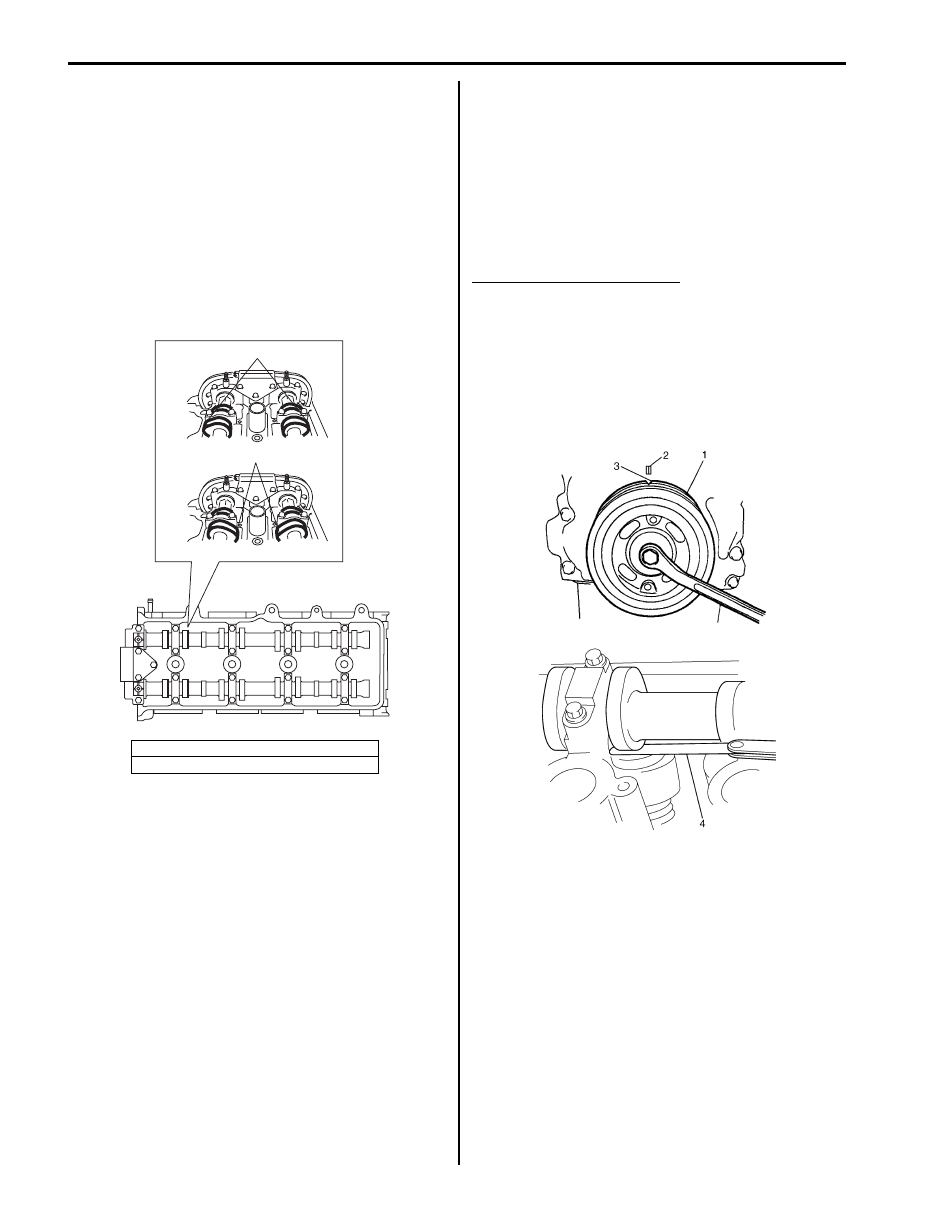

3) Using 17 mm wrench, turn crankshaft pulley (1)

clockwise until index (2) of cylinder block and index

(3) of crankshaft pulley (1) are aligned.

4) Check whether cam position (1) of No.1 cylinder is at

the specified position [A] as shown in figure.

If cam position is [B], locate cam position to [A] by

turning crankshaft one rotation.

5) Check valve lashes with thickness gauge (4)

according to the following procedure.

a) Check valve lashes of cylinder No.1.

b) Turn crankshaft pulley by 180

° clockwise.

c) Check valve lashes of cylinder No.3.

d) In the same manner as b) – c), check valve

lashes of cylinder No.4 then cylinder No.3.

If valve lash is out of specification, record valve lash and

adjust it to specification by replacing shim.

Valve clearance specification

When cold (Coolant temperature is 15 – 25

°C (59 –

77

°F)):

• Intake: 0.18 – 0.22 mm (0.007 – 0.009 in.)

• Exhaust: 0.28 – 0.32 mm (0.011 – 0.013 in.)

When hot (Coolant temperature is 60 – 68

°C (140 –

154

°F)):

• Intake: 0.21 – 0.27 mm (0.008 – 0.011 in.)

• Exhaust: 0.30 – 0.36 mm (0.012 – 0.014 in.)

[A]: TDC in compression for No.1 cylinder

[B]: TDC in exhaust for No.1 cylinder

[A]

[B]

1

1

I5JB0A142064-01

I5JB0A142065-01