Suzuki Grand Vitara JB416 / JB420. Manual - part 87

1D-16 Engine Mechanical: For M16A Engine with VVT

17) With hose connected, detach A/C compressor from

its bracket (if equipped) referring to “Compressor

Assembly Removal and Installation for M16 Engine

Model in Section 7B”.

CAUTION

!

Suspend removed A/C compressor at a place

where no damage will be caused during

removal and installation of engine assembly.

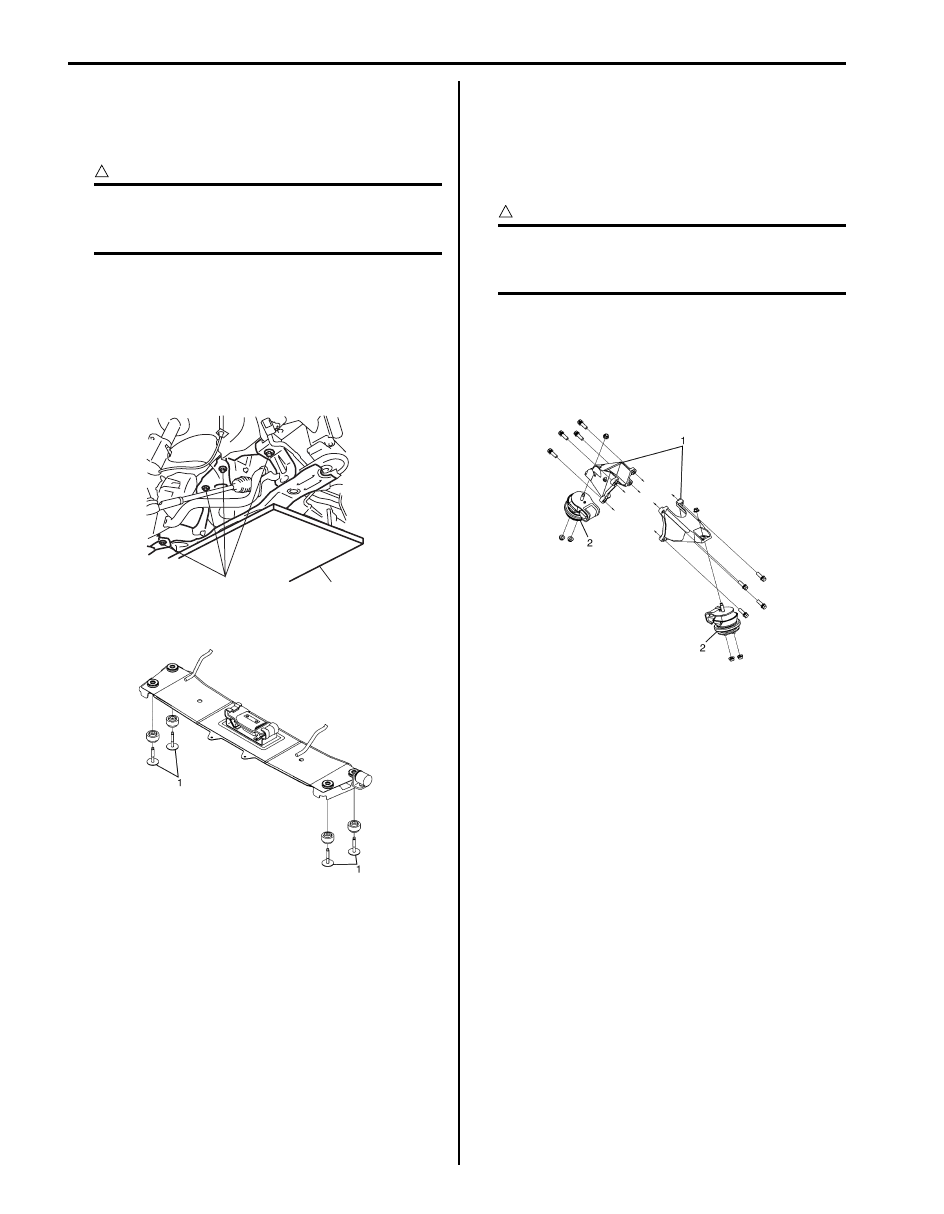

18) Support front suspension frame and engine rear

mounting member using jack (2).

19) Carry out Step 1) to 12) of “Removal” under “Front

Suspension Frame, Stabilizer Bar and/or Bushings

Removal and Installation in Section 2B” in order to

lower engine with front suspension frame.

20) Remove front suspension frame mounting bolt (1).

21) Remove engine rear mounting member bolt (1).

22) Before lowering engine with transmission and front

suspension frame from engine compartment,

recheck to make sure all hoses, electric wires and

cables are disconnected from engine.

23) Lower engine with transmission and front

suspension frame from engine compartment.

CAUTION

!

Before lowering engine, in order to avoid

damage to A/C compressor and P/S pump,

make clearance by rising them.

24) Disconnect transmission from engine referring to

“Manual Transmission Assembly Dismounting and

Remounting in Section 5B”, if necessary.

25) Remove engine with engine front mounting bracket

(1) from engine front mounting (2), if necessary.

26) Remove clutch cover and clutch disc referring to

“Clutch Cover, Clutch Disc and Flywheel Removal

and Installation in Section 5C”, if necessary.

1

2

I5JB0A141017-02

I5JB0A141018-02

I5JB0A141019-01