Suzuki Grand Vitara JB416 / JB420. Manual - part 83

1C-17 Engine Electrical Devices:

Specifications

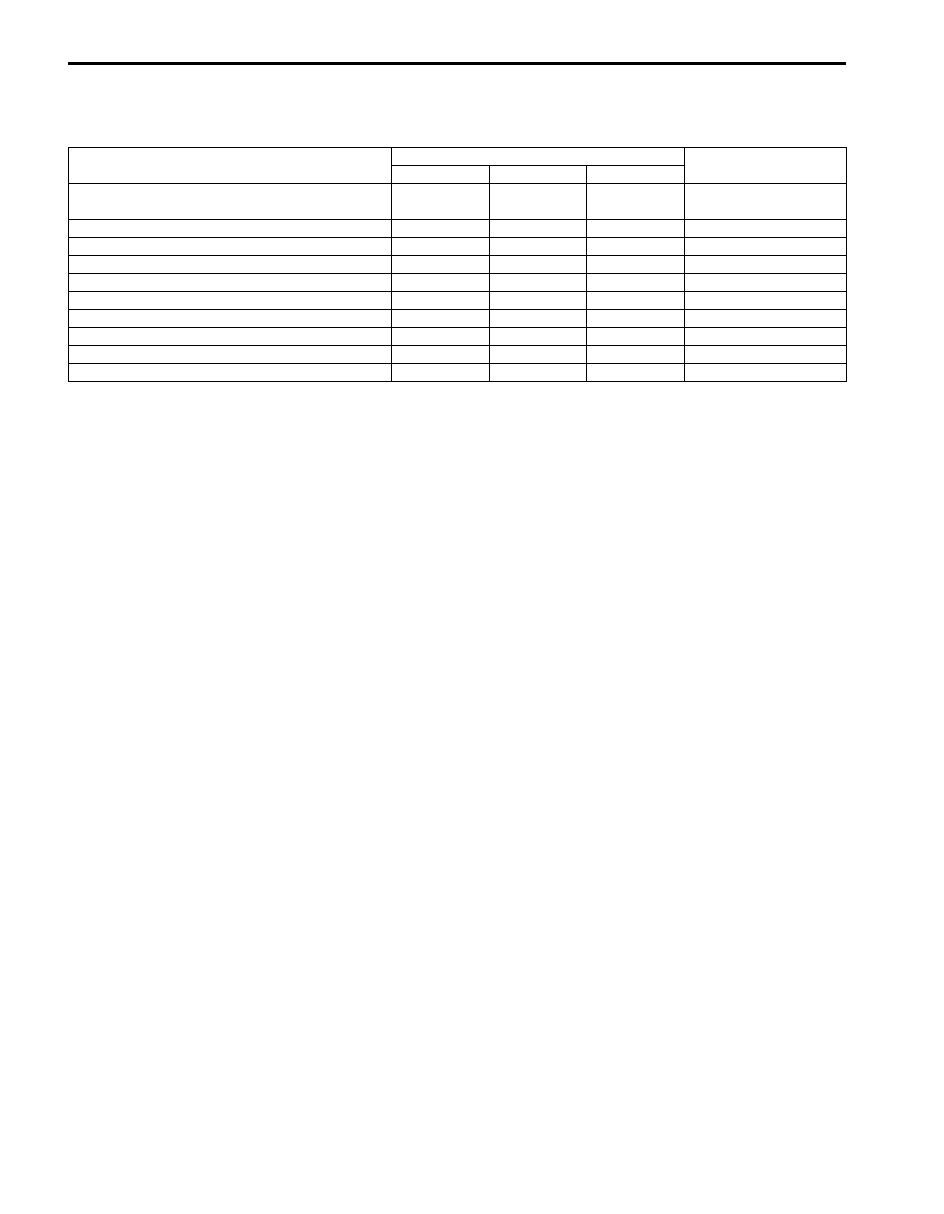

Tightening Torque Specifications

S5JB0A1307001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fastener Information in Section 0A”.

Fastening part

Tightening torque

Note

N

⋅m

kgf-m

lb-ft

Accelerator pedal position (APP) sensor

assembly nut

6.0

0.6 4.5

APP sensor assembly bracket nut

6.0

0.6

4.3

ECT sensor

12.5

1.25

9.0

A/F sensor

45

4.5

32.5

Heated oxygen sensor

45

4.5

32.5

CMP sensor bolt

11

1.1

8.0

CKP sensor bolt

11

1.1

8.0

CKP sensor bolt

10

1.0

7.5

Knock sensor

22

2.2

16.0

MAF and IAT sensor screw

1.5

0.15

1.1