Suzuki Grand Vitara JB416 / JB420. Manual - part 79

1C-1 Engine Electrical Devices:

Engine

Engine Electrical Devices

Repair Instructions

Engine Control Module (ECM) Removal and

Installation

S5JB0A1306004

CAUTION

!

As ECM consists of precision parts, be

careful not to expose it to excessive shock.

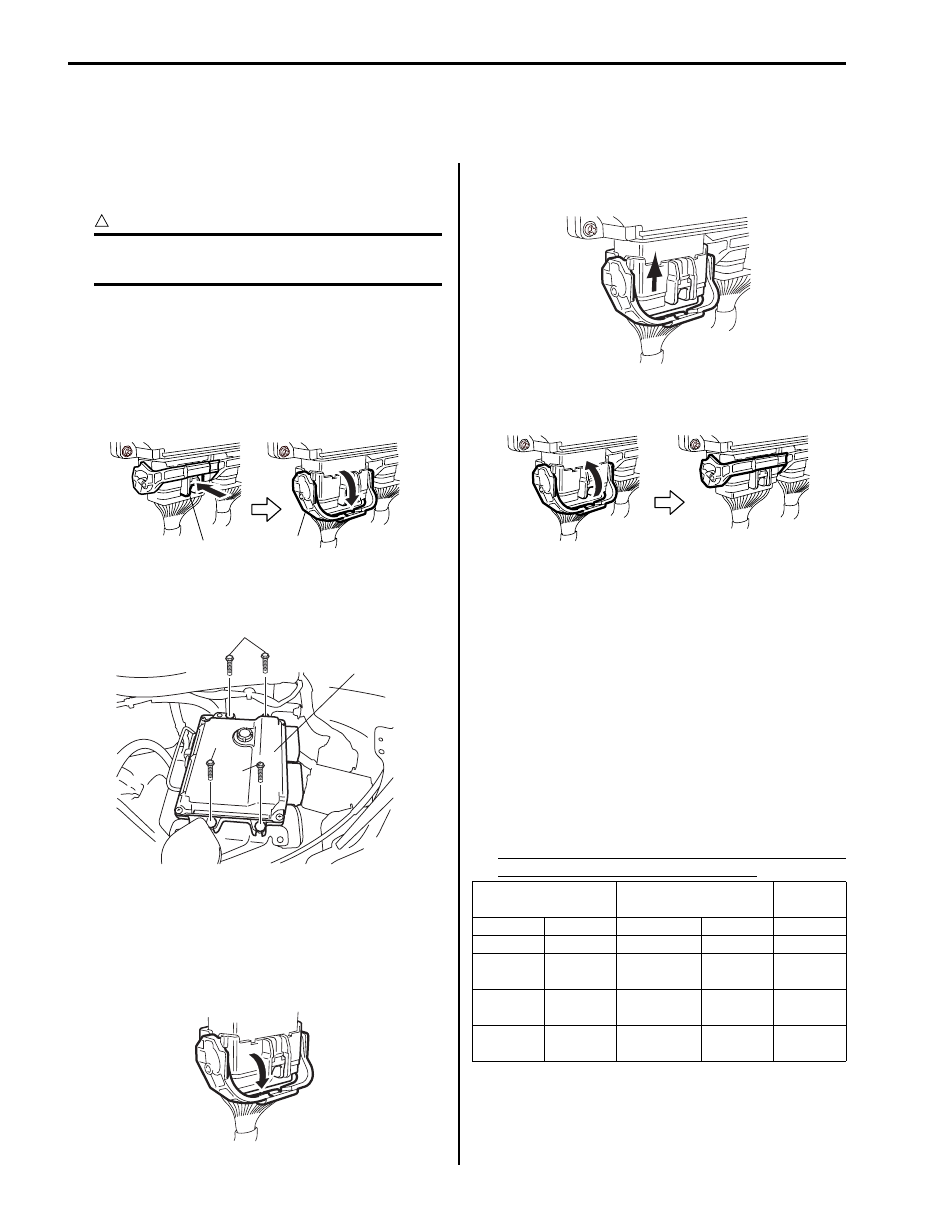

Removal

1) Disconnect negative cable at battery.

2) Remove ECM cover.

3) Disconnect connectors from ECM as follows.

a) Push lock (1) to release locking of lock lever (2).

b) Turn lock lever to arrow direction until it stops.

4) Remove ECM (1) from its bracket by removing its

mounting bolts (2).

Installation

Reverse removal procedure noting the following:

• Connect connectors to ECM as follows.

a. Make sure that lock lever of ECM connector is

unlock position.

b. Insert ECM connectors to ECM until it stops with

unlocked lock lever.

c. Lock ECM connectors securely by pulling its lock

lever up.

Manifold Absolute Pressure (MAP) Sensor

Inspection

S5JB0A1306005

1) Disconnect connector from MAP sensor.

2) Remove MAP sensor from intake manifold.

3) Arrange 3 new 1.5 V batteries (2) in series (check

that total voltage is 4.5 – 5.0 V) and connect its

positive terminal to “Vin” terminal of sensor and

negative terminal to “Ground” terminal. Then check

voltage between “Vout” and “Ground”. Also, check if

voltage reduces when vacuum is applied up to 400

mmHg by using vacuum pump (3).

If check result is not satisfactory, replace MAP

sensor (1).

Output voltage (When input voltage is 4.5 – 5.5 V,

ambient temp. 20 – 30

°C, 68 – 86 °F)

1

2

I4RS0A130003-01

1

2

2

2

I5JB0A130012-03

I4RS0B130021-01

Altitude

(Reference)

Barometric pressure

Output

voltage

(ft)

(m)

(mmHg)

(kPa)

(V)

0 – 2000

0 – 610

760 – 707 100 – 94 3.3 – 4.3

2001 –

5000

611 –

1524

Under 707

over 634

94 – 85

3.0 – 4.1

5001 –

8000

1525 –

2438

Under 634

over 567

85 – 76

2.7 – 3.7

8001 –

10000

2439 –

3048

Under 567

over 526

76 – 70

2.5 – 3.3

I4RS0B130022-01

I4RS0A130004-01