Dacia SuperNova (engine E7J). Manual - part 13

ENGINE E7J-A-2/60

10

10 - 28

ENGINE AND LOWER ENGINE UNITS

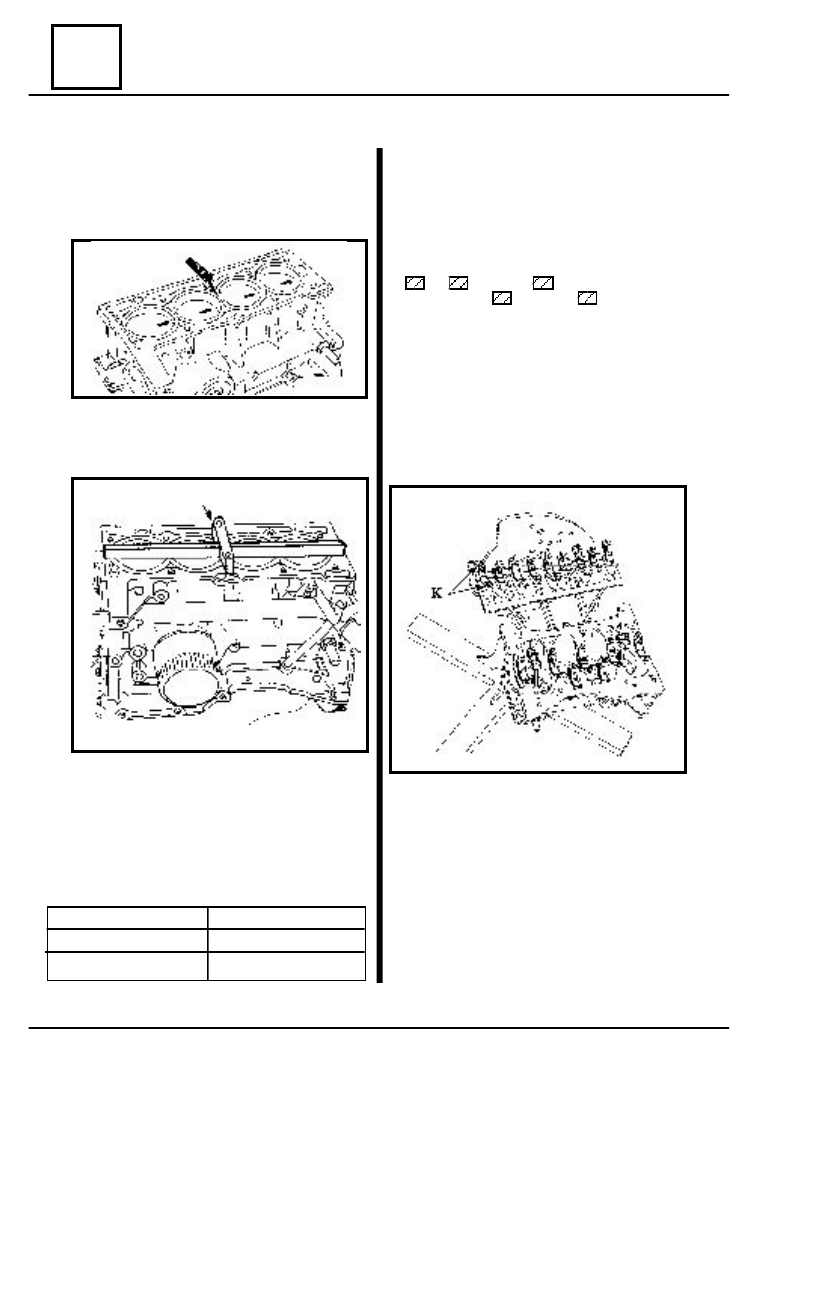

The set is mounted in the crankcase in the

previously established order, and it is made

sure that a 0.1 mm-long wedge passes

between the jackets

The jackets are blocked by means of

MOT.484 stand.

Mount connecting-rod bearings

(connecting rod bearings are identical).

The crankpins and the bearings are

oiled.

The bearing caps are mounted. On no.

1 cap (in the K area) a thin layer of

RHODORSEAL 5661 is applied.

The screws are tightened at 2.5 daNm,

and then at an angle of 43

o

+/-6

o

.

The axial play of the crankshaft is

checked; it must be within:

* 0.045 and 0.852 with wear;

* 0.045 and 0.252 without wear.

MOT. 484

THE CYLINDER CRANKCASE

Take up the bearings of bearing on the housing

cylinders. Half-be aring liners that are to be

mounted on crankshaft bearing are provided with

oiling holes.

Be a ring liners a re ma tchning w ith the

crankshaft in two classes, as follows :

Marking on bearing linersMarking on crankshaft

Red

A

Blue

B

Identification of matching classes on

crankshaft is done by marking on the

counter-balance from number 5 bearing

liner.

Crankshaft marking example :

A

A

B

A

B

RECOVERY ENGINE