Dacia Solenza (engine E7J). Manual - part 70

GENERAL

30 - 11

30

Braking system diagnostic

II.

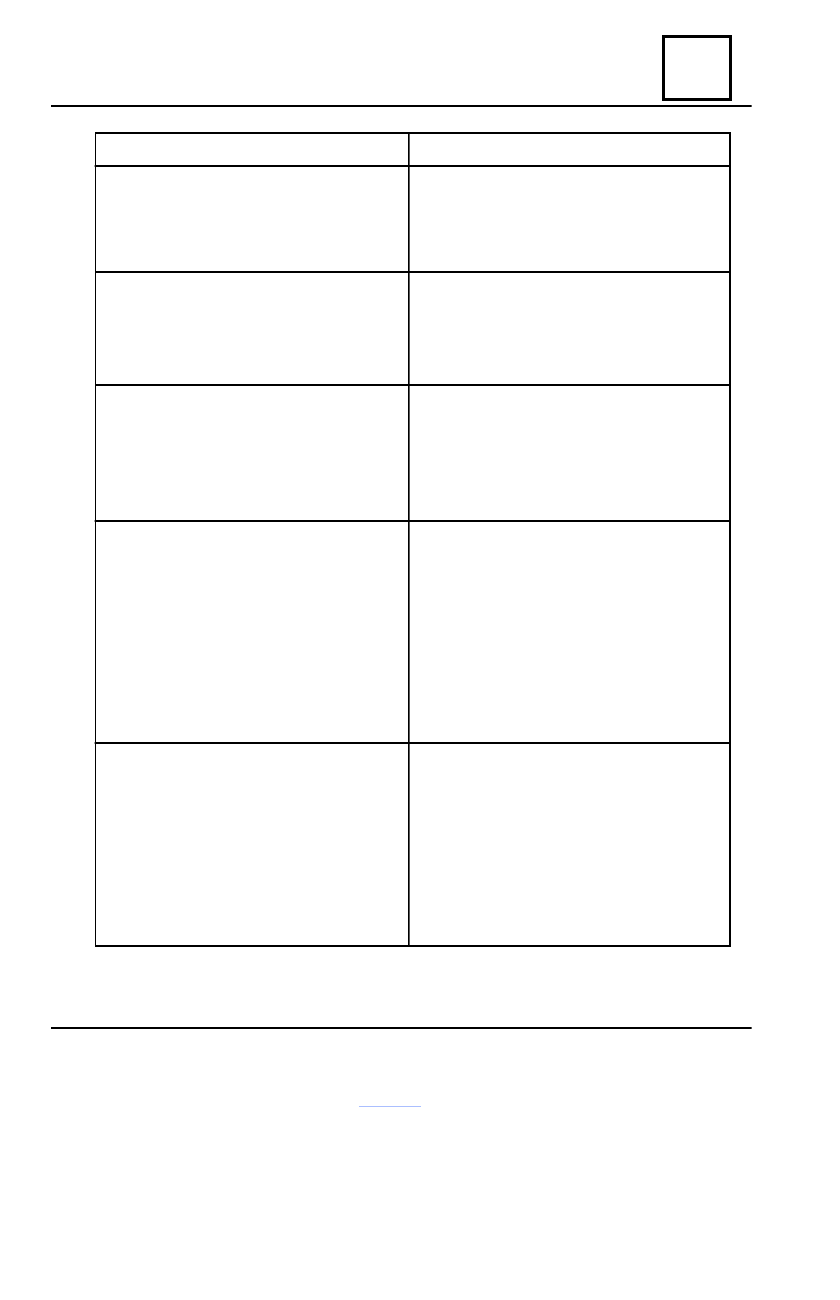

CONSTANT EFFECT AT BEHAVIOUR

EFFECTS

Brakes not accomplishing the required

braking distance

Vibrating brakes

When braking, the vehicle ( front part)

is left/right deviating

Braking

Heating brakes

POSSIBLE CAUSES

- Non-uniform worn brake linings (backing

off);

- Brake linings slightly greased;

- Springs with modified characteristics.

- Brake disks with high wobbling;

- Inconstancy brake disks width;

- Particles abnormal deposit on brake disks

(oxidation between linings and disk).

- Front axle suspension, steering (to be

checked);

- Stuck piston;

- Tires – wear, inflation pressure;

- Rigid duct narrowed (flattening).

- Stuck piston;

Automatic adjustment : hand brake cable very

tighten.

REMARK :

Automatic recovering is performed by

means of the brake pedal, if there is no ab-

normal tension in the hand brake cable

when released (hand brake released).

- Return spring.

- Insufficient hydraulic stroke of the brake

pump, not allowing the return at rest of the

brake pump pistons ( brake pump remaining

under pressure);

- Stuck pistons or hardly returning;

- Rigid duct narrowed (flattening);

- Defective adjustment of the hand brake

control.