Dacia Solenza (engine E7J). Manual - part 58

CV JH3 - 051

21

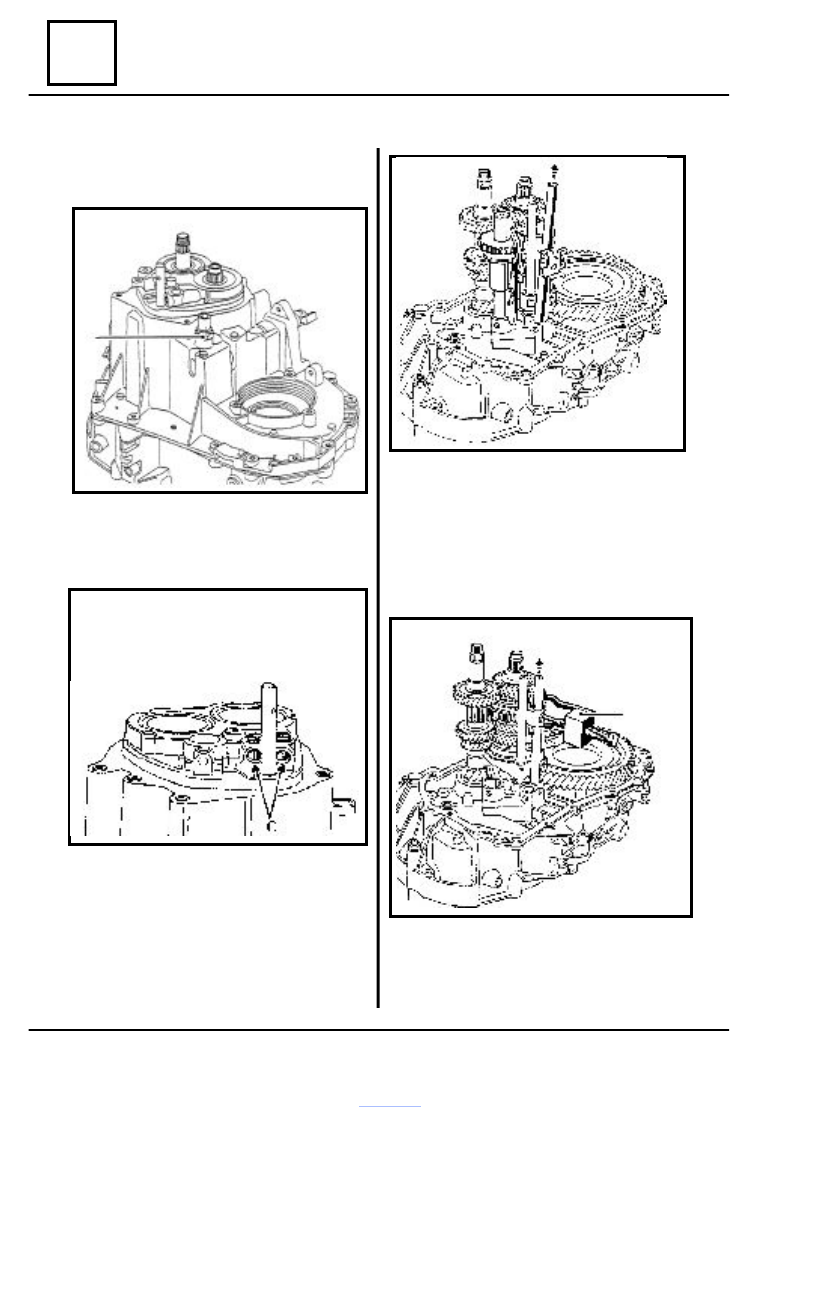

MECHANICAL GEARBOX

21 - 12

A

C.V. 949

Dismount the reverse driving contact (A).

In order to recover the balls and the lock-

ing springs of the 1-2 and 3-4 shafts, two

magnets placed in the C orifices are used.

Pull the control shaft towards exterior and

separate the crankcases

Dismount the reverse driving control shaft

and the 5-th gear.

Remove the pin of the 3-4 fork by means

of the C.V. 949 device and dismount the 3-4

shaft and fork assembly.

Gearbox dismounting