Dacia Solenza (engine E7J). Manual - part 13

ENGINE

E7J-262

10

ENGINE ASSEMBLY

10 - 27

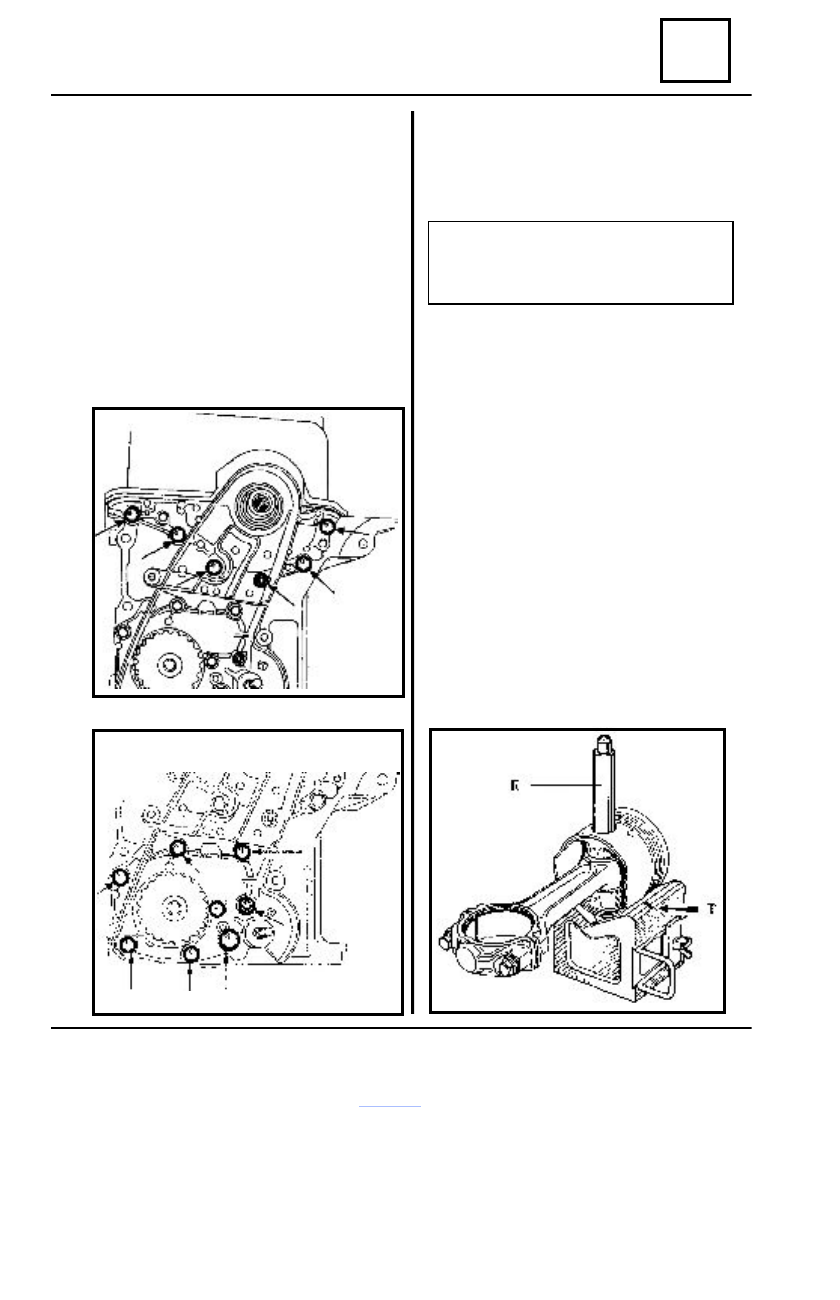

CYLINDERS BLOCK DISMOUNTING

Dismount:

- water inlet pipe and oil dipper rod

guide ( their sealing is performed by means of

rubber rings that must be replaced at each dis-

mounting);

- clutch;

- engine flywheel, immobilized by means

of the MOT 582;

- lower crankcase;

- crankshaft gear;

- tightening roller;

- crankshaft closing casing;

Dismounting – Remounting

-

water pump.

Dismount the oil pump attachment screws.

Dismount the oil pump and its driving chain.

Mark the connecting rod caps compared

with the connecting rod body.

ATTENTION!

Do not use punches for marking in or-

der to avoid cracks occurring; a perma-

nent marker is to be used.

Dismount

- connecting rods caps and the bearings;

- jackets maintaining device MOT 484 or

clamps MOT 588;

- assembly jackets-pistons-connecting

rods;

- bearings caps and their bearings;

- crankshaft and axial clearance bearings;

- bearings from the cylinders block.

PISTONS SHAFTS DI

SMOUNTING

Place the piston on the support lining up

the piston bolt (shaft) with the gap whole from

the support (two T lines for marking the whole

center are facilitating the lining up).

Remove the bolts using a press by means

of the extraction mandrel E.