Dacia Pick-Up 1304/1305/1307. Manual - part 57

MANUAL GEARBOX

21

21 - 34

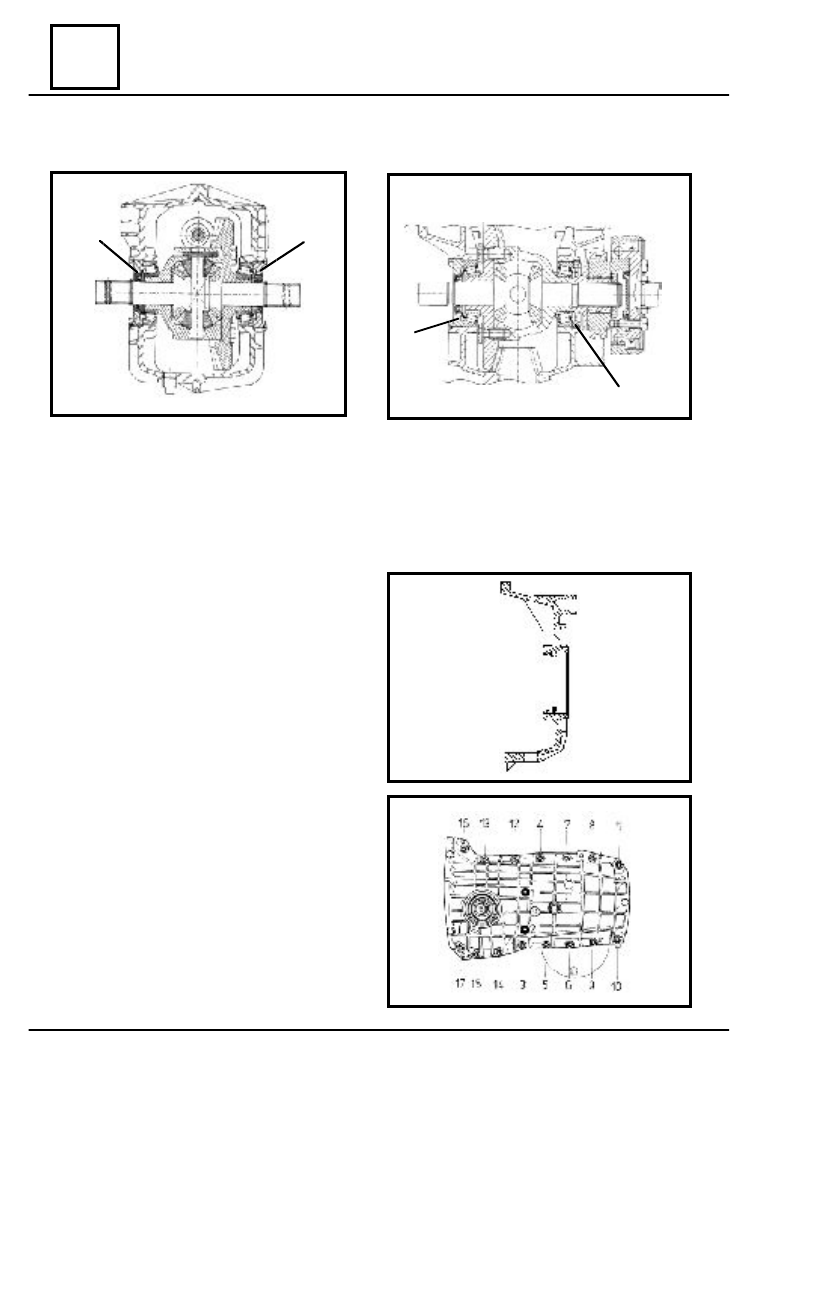

DIFFERENTIAL GEAR BEARINGS ADJUSTMENT ( G.B. 365 and 51 C )

The differential gear bearings adjustment is performed by means of the nuts (1) and (2).

Mount the annular oil seal rings on the adjustment nuts.

Grease the adjustment nuts threads with sealing paste LOCTITE 518

NOTE:

Before mounting, the annular oil rings will be immersed in oil 80W/90.

Mount the outer rings of the differential gear

bearing in the half crankcases so that they are

protruding as compared to the inner side of the

half crankcase.

Place the differential gear in the right side half

crankcase.

Place the left side half crankcase and

assemble it by means of screws.

Tighten the screw to the required

moment,observing the tightening order specified

in the drawing.

M 7 : 1,9 - 2,4 daNm

M 8 : 2,8 - 3,3 daNm

REPAIR

1

2

2

1