содержание .. 41 42 43 44 ..

Peugeot 405. Manual - part 43

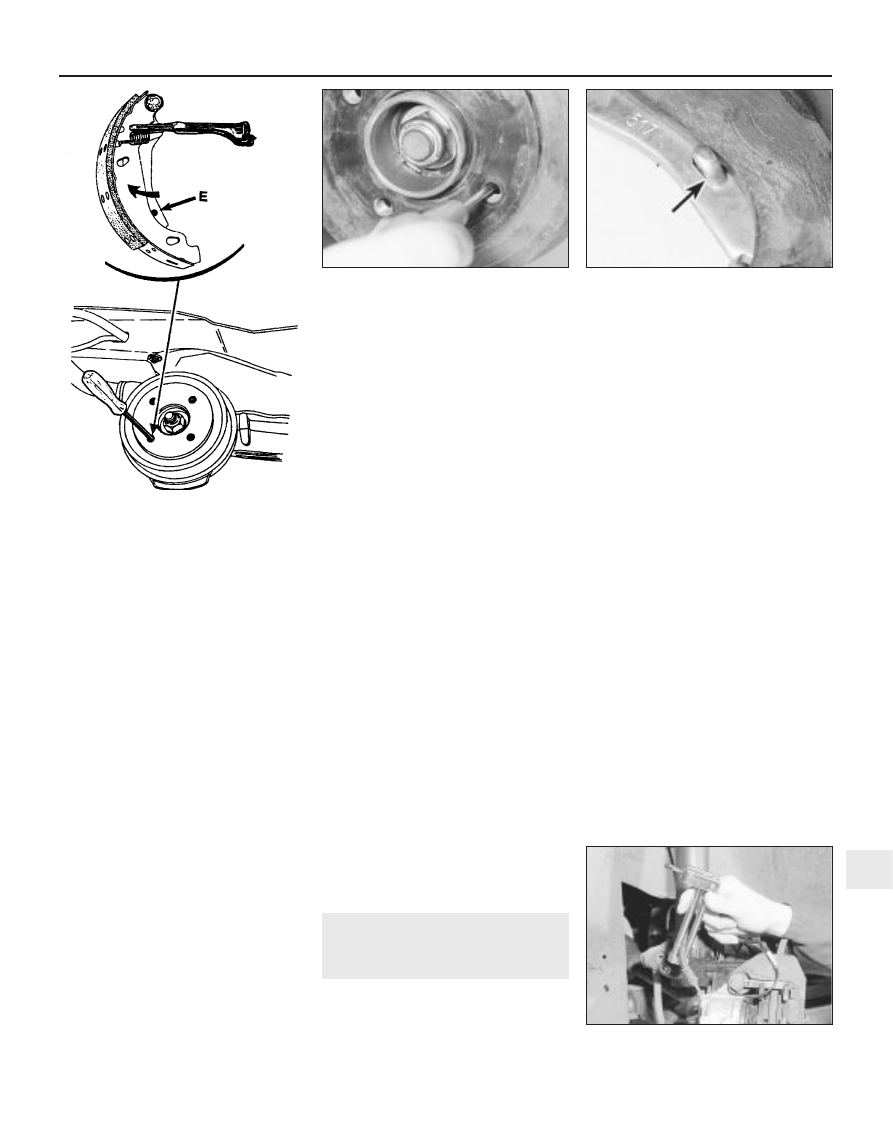

that it contacts the handbrake operating

lever on the trailing brake shoe. Push the

lever until the stop-peg slips behind the

brake shoe web, allowing the brake shoes

to retract fully (see illustrations). The

brake drum can now be withdrawn.

Inspection

Note: If either drum requires renewal, BOTH

should be renewed at the same time, to

ensure even and consistent braking. New

brake shoes should also be fitted.

4 Working carefully, remove all traces of

brake dust from the drum, but avoid inhaling

the dust, as it is injurious to health.

5 Clean the outside of the drum, and check it

for obvious signs of wear or damage, such as

cracks around the roadwheel bolt holes;

renew the drum if necessary.

6 Examine carefully the inside of the drum.

Light scoring of the friction surface is normal,

but if heavy scoring is found, the drum must

be renewed. It is usual to find a lip on the

drum’s inboard edge which consists of a

mixture of rust and brake dust; this should be

scraped away, to leave a smooth surface

which can be polished with fine (120- to 150-

grade) emery paper. If, however, the lip is due

to the friction surface being recessed by

excessive wear, then the drum must be

renewed.

7 If the drum is thought to be excessively

worn, or oval, its internal diameter must be

measured at several points using an internal

micrometer. Take measurements in pairs, the

second at right-angles to the first, and

compare the two, to check for signs of ovality.

Provided that it does not enlarge the drum to

beyond the specified maximum diameter, it

may be possible to have the drum refinished

by skimming or grinding; if this is not possible,

the drums on both sides must be renewed.

Note that if the drum is to be skimmed, BOTH

drums must be refinished, to maintain a

consistent internal diameter on both sides.

Refitting

8 If a new brake drum is to be installed, use a

suitable solvent to remove any preservative

coating that may have been applied to its

interior. Note that it may also be necessary to

shorten the adjuster strut length, by rotating

the strut wheel, to allow the drum to pass over

the brake shoes.

9 Ensure that the handbrake lever stop-peg is

correctly repositioned against the edge of the

brake shoe web (see illustration), and ensure

that the mating faces of the hub and brake

drum are clean, then slide the brake drum

onto the hub.

10 Refit and tighten the drum retaining

screw.

11 Depress the footbrake several times to

operate the self-adjusting mechanism.

12 Repeat the above procedure on the

remaining rear brake assembly (where

necessary), then check and, if necessary,

adjust the handbrake cable as described in

Section 17.

13 On completion, refit the roadwheel(s),

then lower the vehicle to the ground and

tighten the wheel bolts to the specified

torque.

10 Front brake caliper - removal,

overhaul and refitting

3

Note: Before starting work, refer to the note at

the beginning of Section 2 concerning the

dangers of hydraulic fluid, and to the warning

at the beginning of Section 4 concerning the

dangers of asbestos dust.

Bendix caliper

Removal

1 Apply the handbrake, then jack up the front

of the vehicle and support it on axle stands

(see “Jacking and Vehicle Support”). Remove

the appropriate roadwheel.

2 Minimise fluid loss by first removing the

master cylinder reservoir cap, and then

tightening it down onto a piece of polythene,

to obtain an airtight seal. Alternatively, use a

brake hose clamp, a G-clamp or a similar tool

to clamp the flexible hose (see illustration).

3 Remove the brake pads as described in

Section 4.

4 Clean the area around the union, then

loosen the fluid hose union nut.

5 Slacken the two bolts securing the caliper

assembly to the hub carrier and remove them

along with the mounting plate, noting which

way around the plate is fitted. Lift the caliper

assembly away from the brake disc, and

unscrew it from the end of the fluid hose. Plug

the open ends of the caliper and hose to

prevent dirt ingress and fluid loss.

Overhaul

6 The caliper can be overhauled after

obtaining the relevant repair kit from a

Peugeot dealer. Ensure that the correct repair

kit is obtained for the caliper being worked on.

Note the locations of all components to

ensure correct refitting, and lubricate the new

seals using clean brake fluid. Follow the

assembly instructions supplied with the repair

kit (see illustration).

Braking system 9•11

9.9 Check that the handbrake lever stop-

peg (arrowed) is against the shoe edge

E Handbrake operating lever stop-peg location

10.2 Using a clamp on the caliper

hydraulic hose

9.3b Releasing the handbrake

operating lever

9

9.3a Using a screwdriver inserted through

the brake drum to release the handbrake

operating lever