содержание .. 33 34 35 36 ..

Peugeot 405. Manual - part 35

6 Connect an exhaust gas analyser to the

vehicle in accordance with the manufacturer’s

instructions.

7 Start the engine and allow it to idle. Turn

the mixture adjustment screw in or out to

obtain the specified CO content (see

illustration).

8 Re-adjust the idle speed as previously

described.

9 On completion, stop the engine, remove all

test equipment and fit a new tamperproof cap

to the screw.

Bosch ML4.1 system

10 The idle speed is non-adjustable. It is

controlled by the idle speed regulator valve.

11 To check the mixture (CO), first ensure

that the conditions in paragraph 3 are met.

12 Connect an exhaust gas analyser to the

vehicle in accordance with the manufacturer’s

instructions.

13 Remove the tamperproof cap from the

mixture adjustment screw on the airflow meter

housing.

14 Turn the screw clockwise to increase and

anti-clockwise to decrease CO content until

the specified CO level is obtained.

15 Remove all test equipment and fit a new

tamperproof plug to the screw.

Bosch LU2-Jetronic system

16 Idle speed is adjusted as described for

the Bosch L3.1 system (see illustration).

17 Idle mixture is not adjustable, and is

automatically regulated by the electronic

control unit according to signals provided by

the oxygen sensor.

Bosch Motronic M1.3 system

18 Idle speed is only adjustable on 8-valve

engines; on 16-valve engines it is controlled

by the ECU. On 8-valve engines use the

procedure given in paragraphs 3 and 4.

19 Adjustment of idle mixture is as given in

paragraphs 5 to 9.

MM8P, Sagem-Lucas 4GJ,

Bosch Motronic 5.1,

Bosch Motronic 3.2 systems

20 Experienced home mechanics with a

considerable amount of skill and equipment

(including a tachometer and an accurately

calibrated exhaust gas analyser) may be able

to check the exhaust CO level and the idle

speed. However, if these are found to be in

need of adjustment, the car must be taken to

a suitably-equipped Peugeot dealer for further

testing. Neither the mixture adjustment

(exhaust gas CO level) nor the idle speed are

adjustable, and should either be incorrect, a

fault must be present in the fuel injection

system.

12 Throttle housing -

removal and refitting

2

Note: At the time or writing no information

was available for the Sagem-Lucas system.

Removal

1 Disconnect the battery negative terminal.

Bosch Jetronic system

2 Remove the airflow meter with reference to

Section 2.

3 Disconnect the accelerator cable from the

throttle housing.

4 Either drain the cooling system or clamp

the coolant hoses as close as possible to the

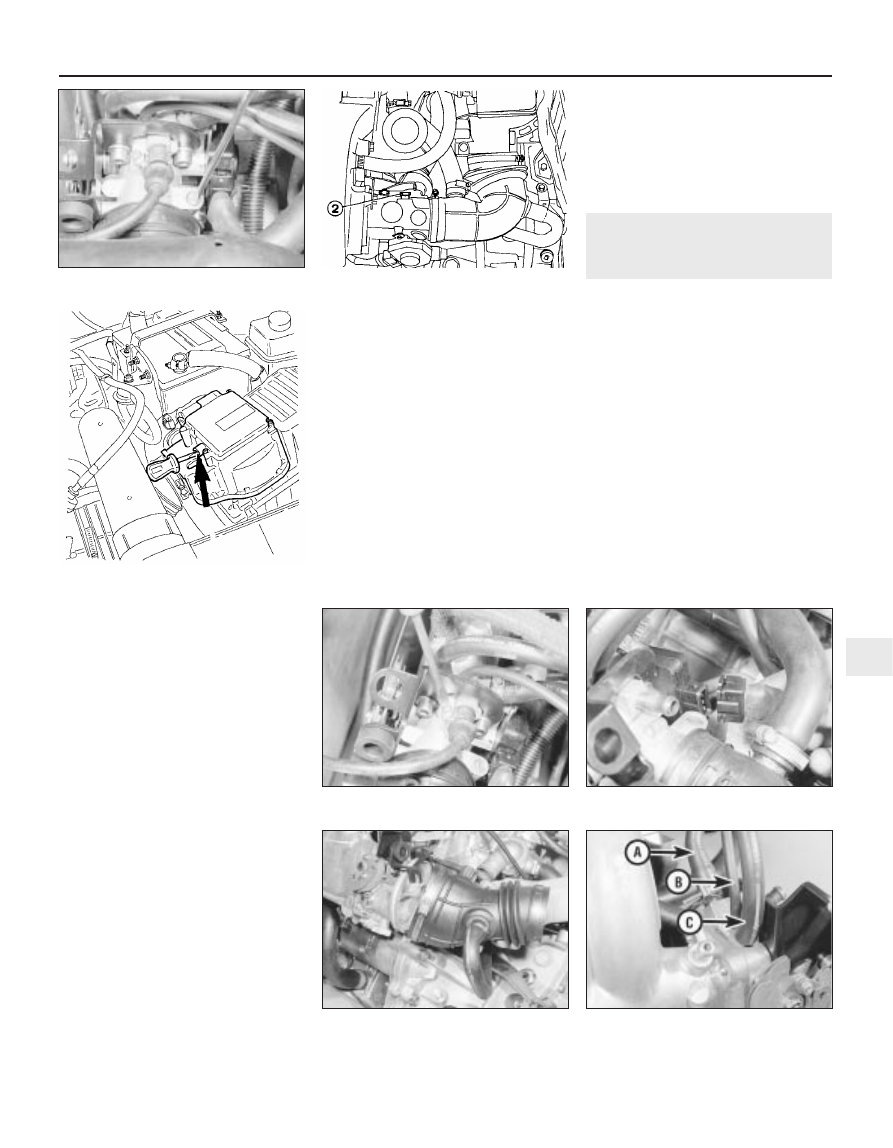

throttle housing, then disconnect the coolant

inlet hose (see illustration).

5 Disconnect the throttle switch wiring multi-

plug (see illustration).

6 Loosen the clip and detach the plastic duct

from the throttle housing (see illustration).

7 Disconnect the coolant return hose,

distributor vacuum hose and breather hose

from the throttle housing (see illustration).

Fuel/exhaust systems - multi-point fuel injection models 4C•5

11.16 Idle speed adjustment screw (2)

(LU2-Jetronic system)

12.7 Disconnect the coolant return (A),

distributor vacuum hose (B)

and breather hose (C)

12.6 Detach the plastic duct

12.5 Disconnecting the multi-plug

12.4 Disconnecting the coolant inlet hose

4C

11.4 Adjusting the idle speed screw on the

Bosch L3.1 system

11.7 Mixture (CO ) adjustment screw on

the airflow meter (Bosch L3.1 system)