содержание .. 18 19 20 21 ..

Peugeot 405. Manual - part 20

sprocket, fitted to the crankshaft, be renewed

at the same time. To renew the chain and

drive sprocket, first remove the crankshaft

timing belt sprocket as described in Section 8.

Unbolt the oil seal carrier from the cylinder

block. The sprocket and chain can then be

slid off the end of the crankshaft. Refer to Part

C for further information.

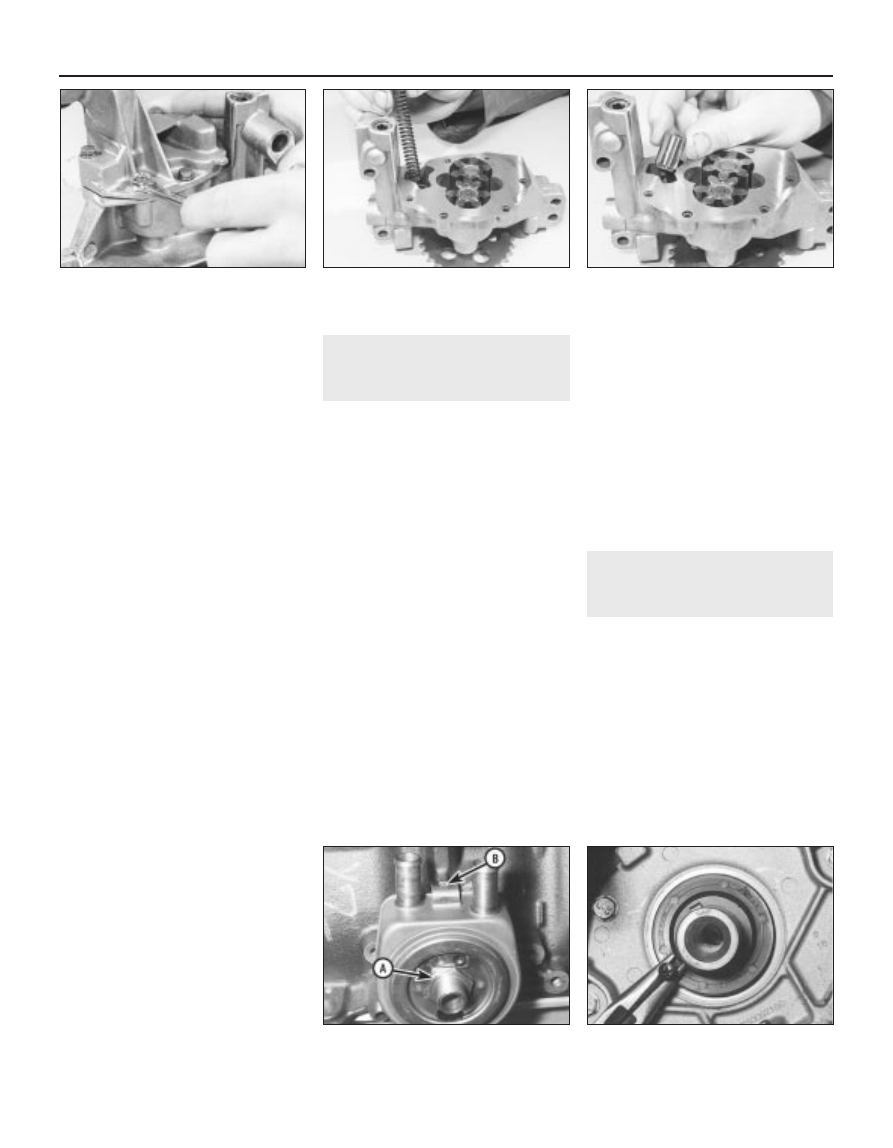

5 Slacken and remove the bolts (along with

the baffle plate, where fitted) securing the

strainer cover to the pump body. Lift off the

strainer cover, and take off the relief valve

piston and spring, noting which way round

they are fitted (see illustrations).

6 Examine the pump rotors and body for

signs of wear ridges or scoring. If worn, the

complete pump assembly must be renewed.

7 Examine the relief valve piston for signs of

wear or damage, and renew if necessary. The

condition of the relief valve spring can only be

measured by comparing it with a new one; if

there is any doubt about its condition, it

should also be renewed. Both the piston and

spring are available individually.

8 Thoroughly clean the oil pump strainer with

a suitable solvent, and check it for signs of

clogging or splitting. If the strainer is

damaged, the strainer and cover assembly

must be renewed.

9 Locate the relief valve spring and piston in

the strainer cover. Refit the cover to the pump

body, aligning the relief valve piston with its

bore in the pump. Refit the baffle plate (where

fitted) and the cover retaining bolts, and

tighten them securely.

Refitting

10 Offer up the spacer plate (where fitted),

then locate the pump sprocket with its drive

chain. Seat the pump on the base of the

cylinder block/crankcase. Refit the pump

retaining bolts, and tighten them to the

specified torque setting.

11 Where necessary, slide the sprocket

cover into position on the pump. Refit its

retaining bolts, tightening them securely.

12 Refit the sump as described in Section 13.

15 Oil cooler -

removal and refitting

2

Note: The oil cooler is not fitted to all models.

Removal

1 Firmly apply the handbrake, then jack up

the front of the vehicle and support it on axle

stands (see “Jacking and Vehicle Support”).

2 Drain the cooling system as described in

Chapter 1. Alternatively, clamp the oil cooler

coolant hoses directly above the cooler, and

be prepared for some coolant loss as the

hoses are disconnected.

3 Position a suitable container beneath the oil

filter. Unscrew the filter using an oil filter

removal tool if necessary, and drain the oil

into the container. If the oil filter is damaged or

distorted during removal, it must be renewed.

Given the low cost of a new oil filter relative to

the cost of repairing the damage which could

result if a re-used filter springs a leak, it is

probably a good idea to renew the filter in any

case.

4 Release the hose clips, and disconnect the

coolant hoses from the oil cooler.

5 Unscrew the oil cooler/oil filter mounting

bolt from the cylinder block, and withdraw the

cooler. Note the locating notch in the cooler

flange, which fits over the lug on the cylinder

block (see illustration). Discard the oil cooler

sealing ring; a new one must be used on

refitting.

Refitting

6 Fit a new sealing ring to the recess in the

rear of the cooler, then offer the cooler to the

cylinder block.

7 Ensure that the locating notch in the cooler

flange is correctly engaged with the lug on the

cylinder block, then refit the mounting bolt

and tighten it securely.

8 Fit the oil filter, then lower the vehicle to the

ground. Top-up the engine oil (refer to

“Weekly Checks”).

9 Refill or top-up the cooling system (as

applicable) -see Chapter 1. Start the engine,

and check the oil cooler for signs of leakage.

16 Crankshaft oil seals - renewal

4

Right-hand oil seal

1 Remove the crankshaft sprocket and

flanged spacer as described in Section 8.

Secure the timing belt clear of the working

area, so that it cannot be contaminated with

oil. Make a note of the correct fitted depth of

the seal in its housing.

2 Punch or drill two small holes opposite each

other in the seal. Screw a self-tapping screw

into each, and pull on the screws with pliers to

extract the seal (see illustration). The seal can

also be levered out. Use a flat-bladed

screwdriver, but take care not to damage the

crankshaft shoulder or seal housing.

2B•22 XU engine in-car repair procedures

14.5a Remove the oil pump cover

retaining bolts . . .

14.5c . . . and relief valve piston, noting

which way round it is fitted

16.2 Using a self-tapping screw and pliers

to remove the crankshaft oil seal

15.5 Oil cooler/oil filter mounting bolt (A)

and locating notch (B)

14.5b . . . then lift off the cover and

remove the spring . . .