Nissan Frontier D40. Manual - part 843

CHASSIS AND BODY MAINTENANCE

MA-53

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

2.

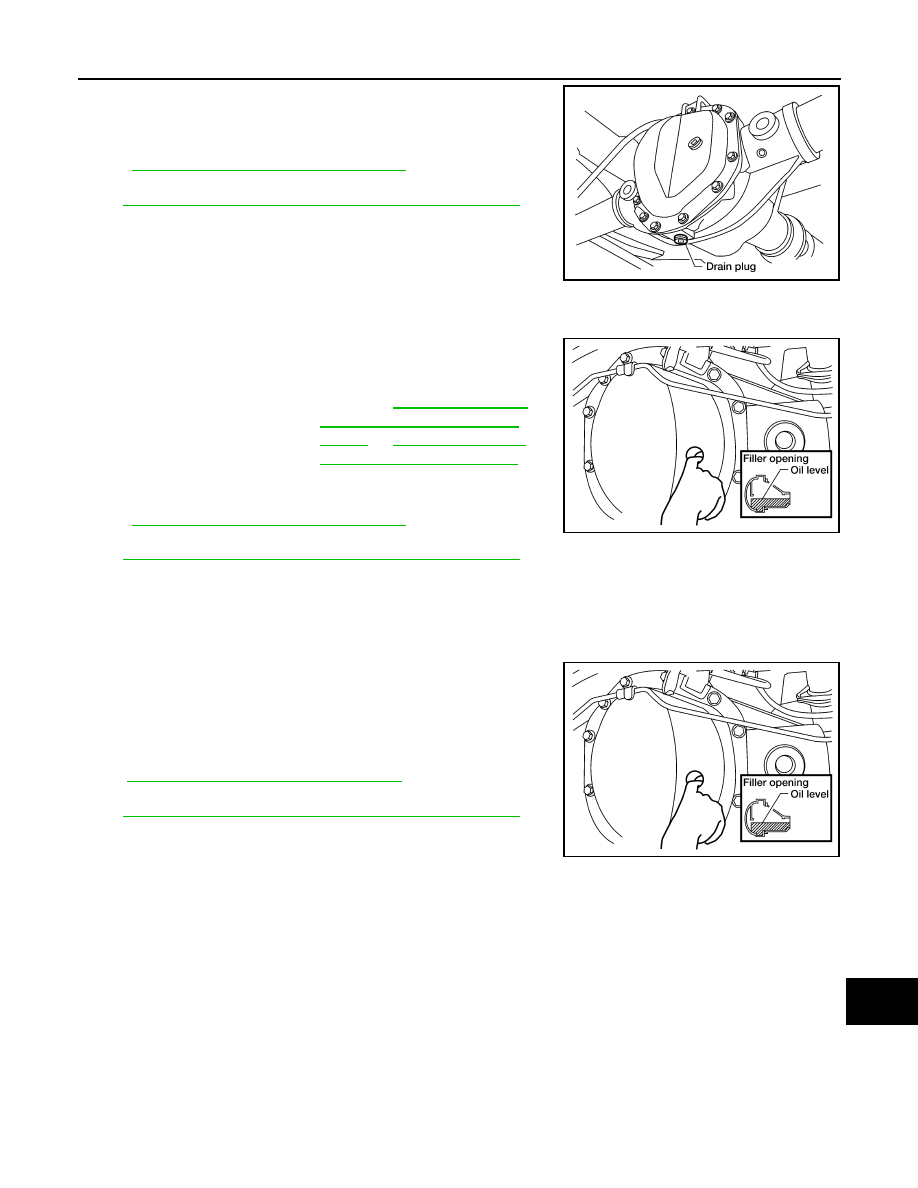

Remove the drain plug from the rear final drive assembly to

drain the differential gear oil.

3.

Install the drain plug with sealant applied on the threads to the

rear final drive assembly. Tighten to the specified torque. Refer

to

DLN-255, "Disassembly and Assembly"

.

• Use High Performance Thread Sealant or equivalent. Refer to

GI-22, "Recommended Chemical Products and Sealants"

FILLING

1.

Remove the filler plug from the rear final drive assembly.

2.

Fill the rear final drive assembly with new differential gear oil

until the level reaches the specified level near the filler plug hole.

3.

Install the filler plug with sealant applied on the threads to the

rear final drive assembly. Tighten to the specified torque. Refer

to

DLN-255, "Disassembly and Assembly"

.

• Use High Performance Thread Sealant or equivalent. Refer to

GI-22, "Recommended Chemical Products and Sealants"

DIFFERENTIAL GEAR OIL : Checking Differential Gear Oil

INFOID:0000000005612458

DIFFERENTIAL GEAR OIL LEAKAGE AND LEVEL

1.

Make sure that differential gear oil is not leaking from the rear final drive assembly or around it.

2.

Check the differential gear oil level from the filler plug hole as

shown.

CAUTION:

Do not start engine while checking differential gear oil level.

3.

Install the filler plug with sealant applied on the threads to the

rear final drive assembly. Tighten to the specified torque. Refer

to

DLN-255, "Disassembly and Assembly"

.

• Use High Performance Thread Sealant or equivalent. Refer to

GI-22, "Recommended Chemical Products and Sealants"

DIFFERENTIAL GEAR OIL : Rear Final Drive - M226 (ELD)

INFOID:0000000005272785

DIFFERENTIAL GEAR OIL : Changing Differential Gear Oil

INFOID:0000000005612453

DRAINING

1.

Stop engine.

LDIA0183E

Differential gear oil

grade and capacity

: Refer to

America: Fluids and Lubri-

cants"

or

.

LDIA0127E

LDIA0127E