Nissan Frontier D40. Manual - part 838

ENGINE MAINTENANCE (VQ40DE)

MA-33

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

CHECKING COOLING SYSTEM HOSES

Check hoses for the following:

• Improper attachment

• Leaks

• Cracks

• Damage

• Loose connections

• Chafing

• Deterioration

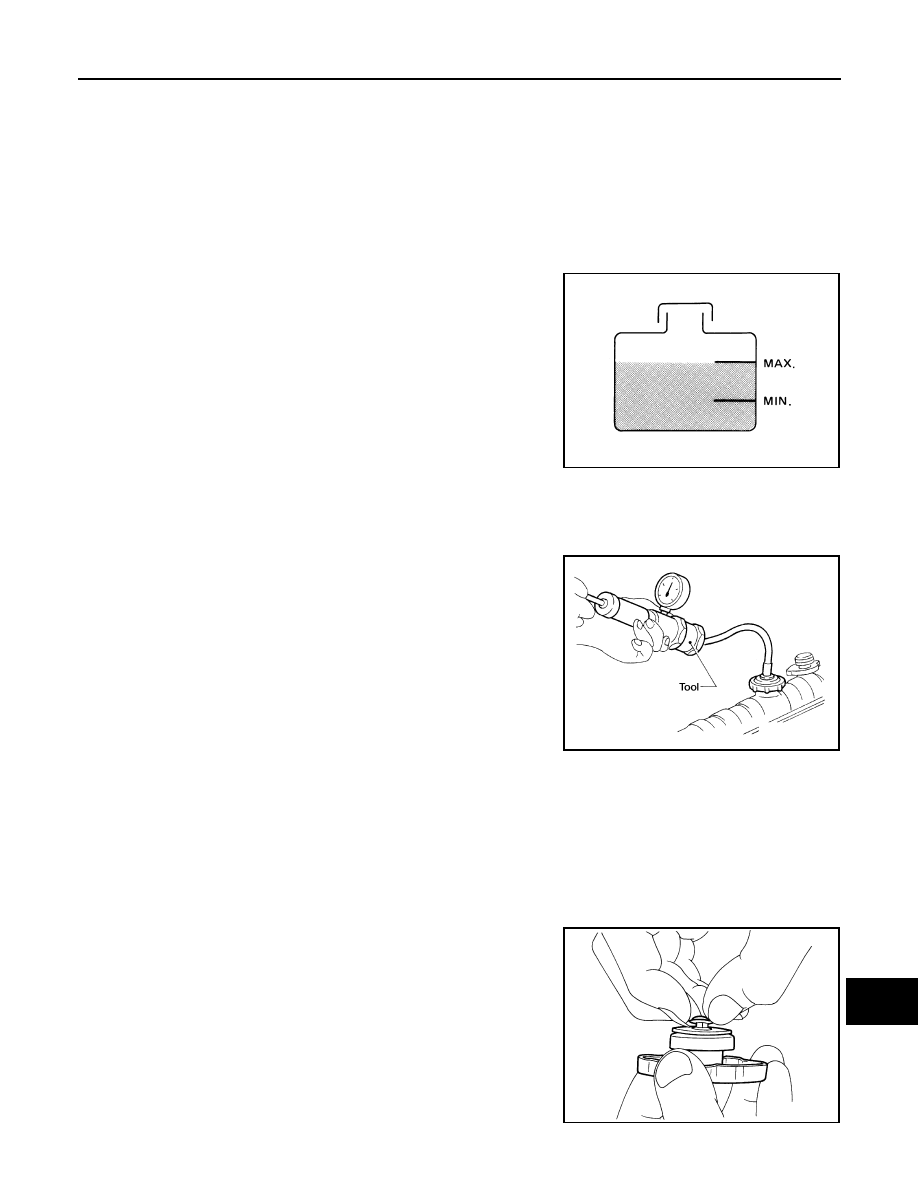

CHECKING RESERVOIR LEVEL

• Check if the engine coolant reservoir tank level is within MIN to

MAX when the engine is cool.

• Adjust engine coolant level as necessary.

CHECKING COOLING SYSTEM FOR LEAKS

WARNING:

Never remove the radiator/reservoir cap when the engine is hot. Serious burns could occur from high

pressure coolant escaping from the radiator or reservoir.

To check for leakage, apply pressure to the cooling system using

Tool.

CAUTION:

Higher pressure than specified may cause radiator damage.

NOTE:

In case that engine coolant decreases, replenish cooling system with

engine coolant.

If any concerns are found, repair or replace damaged parts.

CHECKING RESERVOIR CAP

1.

Inspect the reservoir cap.

• Replace the cap if the metal plunger cannot be seen around the edge of the black rubber gasket.

• Replace the cap if deposits of waxy residue or other foreign material are on the black rubber gasket or

the metal retainer.

NOTE:

Thoroughly wipe out the reservoir filler neck to remove any waxy residue or foreign material.

2.

Pull the negative-pressure valve to open it and check that it

closes completely when released.

• Check that there is no dirt or damage on the valve seat of the

reservoir cap negative-pressure valve.

• Check that there are no abnormalities in the opening and clos-

ing conditions of the negative-pressure valve.

SMA412B

Tool number

: EG17650301 (J-33984-A)

Testing pressure

: 137 kPa (1.4 kg/cm

2

, 20 psi)

WBIA0568E

SMA967B