Nissan Frontier D40. Manual - part 619

EM-208

< ON-VEHICLE REPAIR >

[VQ40DE]

CYLINDER HEAD

2.

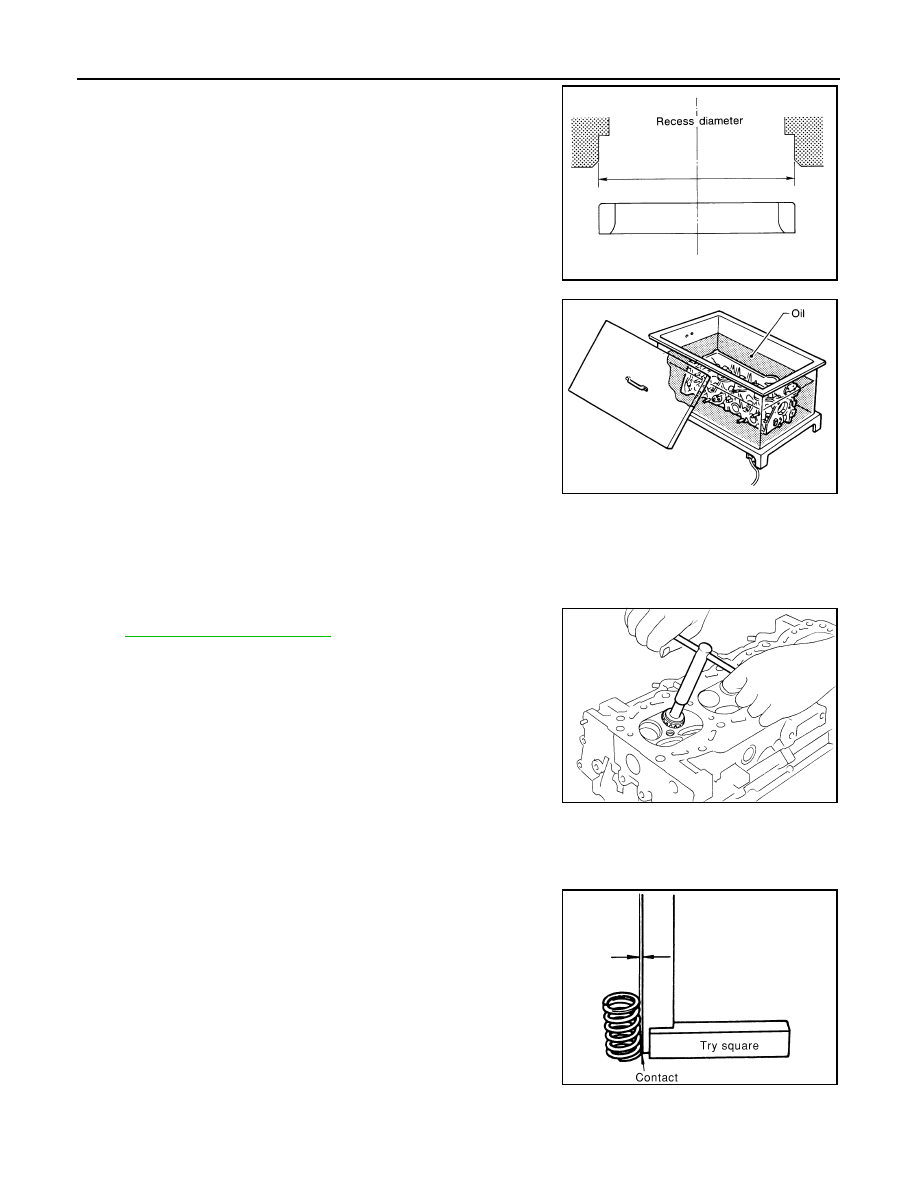

Ream cylinder head recess diameter for service valve seat.

• Be sure to ream in circles concentric to valve guide center.

This will enable valve to fit correctly.

3.

Heat cylinder head to 110

°

to 130

°

C (230

°

to 266

°

F) by soaking

in heated oil.

4.

Provide valve seats cooled well with dry ice. Force fit valve seat into cylinder head.

WARNING:

• Cylinder head contains heat. When working, wear protective equipment to avoid getting burned.

CAUTION:

• Avoid directly touching cold valve seats.

5.

Finish seat to the specified dimensions using suitable tool. Refer

to

.

CAUTION:

When using valve seat cutter, firmly grip cutter handle with

both hands. Then, press on the contacting surface all

around the circumference to cut in a single drive. Improper

pressure on with cutter or cutting many different times may

result in staged valve seat.

6.

Using compound, grind to adjust valve fitting.

7.

Check again for normal contact.

VALVE SPRING SQUARENESS

• Set try square along the side of valve spring and rotate spring.

Measure the maximum clearance between the top face of spring

and try square.

• If it exceeds the limit, replace valve spring.

VALVE SPRING DIMENSIONS AND VALVE SPRING PRESSURE LOAD

Oversize [0.5 mm (0.020 in)]

Intake

: 38.500 - 38.516 mm (1.5157 - 1.5164 in)

Exhaust

: 32.700 - 32.716 mm (1.2874 - 1.2880 in)

SEM795A

SEM008A

SEM934C

Limit

: 2.1 mm (0.083 in)

PBIC0080E