Nissan Frontier D40. Manual - part 544

IGNITION SIGNAL

EC-867

< COMPONENT DIAGNOSIS >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

1.

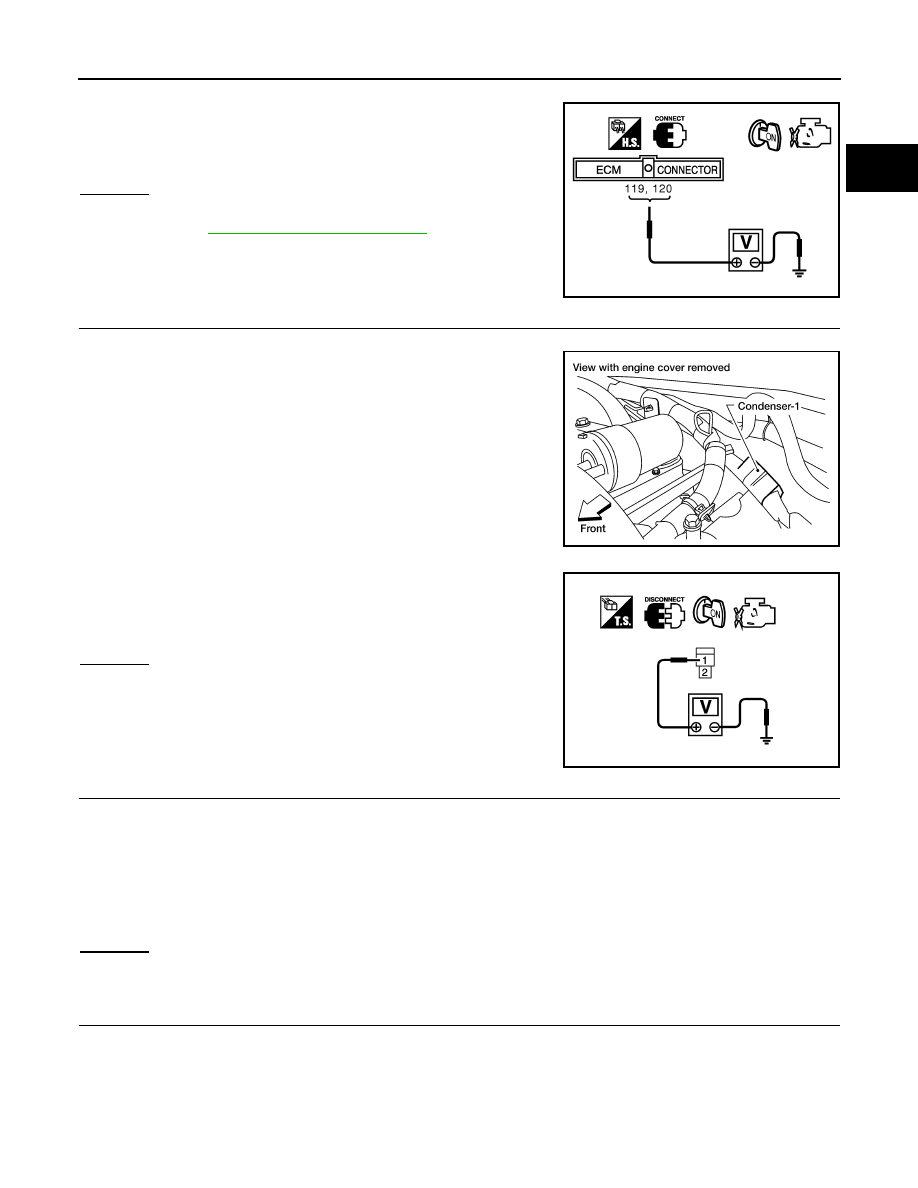

Turn ignition switch OFF, wait at least 10 seconds and then turn it ON.

2.

Check voltage between ECM terminals 119, 120 and ground

with CONSULT-III or tester.

OK or NG

OK

>> GO TO 5.

NG

>> Go to

5.

CHECK IGNITION COIL POWER SUPPLY CIRCUIT-II

1.

Turn ignition switch OFF.

2.

Disconnect condenser-1 harness connector.

3.

Turn ignition switch ON.

4.

Check voltage between condenser-1 terminal 1 and ground with

CONSULT-III or tester.

OK or NG

OK

>> GO TO 8.

NG

>> GO TO 6.

6.

CHECK IGNITION COIL POWER SUPPLY CIRCUIT-III

1.

Turn ignition switch OFF.

2.

Disconnect IPDM E/R harness connector E119.

3.

Check harness continuity between IPDM E/R terminal 3 and condenser-1 terminal 1.

Refer to Wiring Diagram.

4.

Also check harness for short to ground and short to power.

OK or NG

OK

>> GO TO 17.

NG

>> GO TO 7.

7.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E2, F32

• Harness for open or short between condenser-1 and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

Voltage: Battery voltage

MBIB0034E

BBIA0562E

Voltage: Battery voltage

PBIB0624E

Continuity should exist.