Nissan Frontier D40. Manual - part 391

P0455 EVAP CONTROL SYSTEM

EC-255

< COMPONENT DIAGNOSIS >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

4.

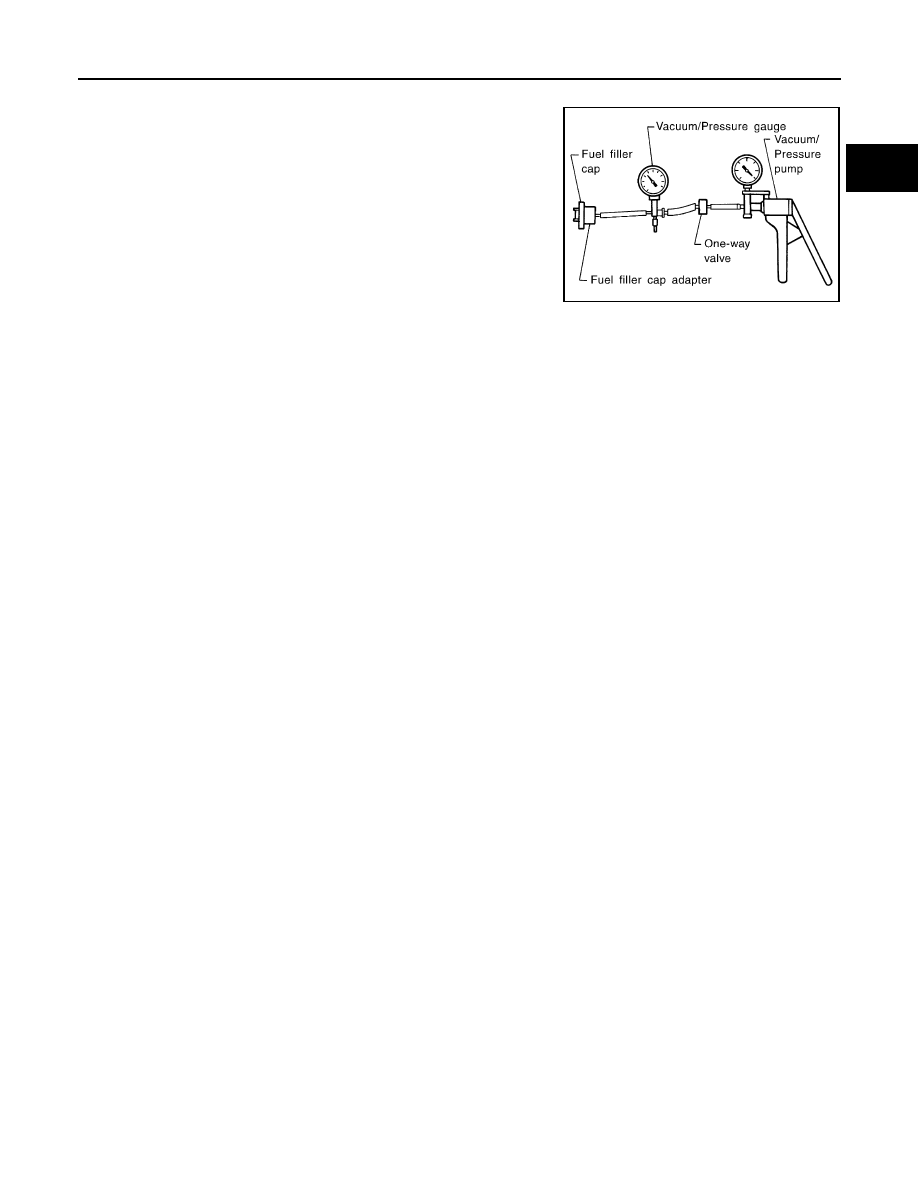

Install fuel filler cap adapter (commercial service tool) to fuel filler cap.

5.

Check valve opening pressure and vacuum.

6.

If out of specification, replace fuel filler cap as an assembly.

CAUTION:

Use only a genuine fuel filler cap as a replacement. If an incor-

rect fuel filler cap is used, the MIL may illuminate.

Pressure:

15.3 - 20.0 kPa

(0.156 - 0.204 kg/cm

2

, 2.22 - 2.90 psi)

Vacuum:

−

6.0 to

−

3.3 kPa

(

−

0.061 to

−

0.034 kg/cm

2

,

−

0.87 to

−

0.48 psi)

SEF943S