Nissan Frontier D40. Manual - part 175

CHG

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM OPERATION

INSPECTION

CHG-9

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

1.

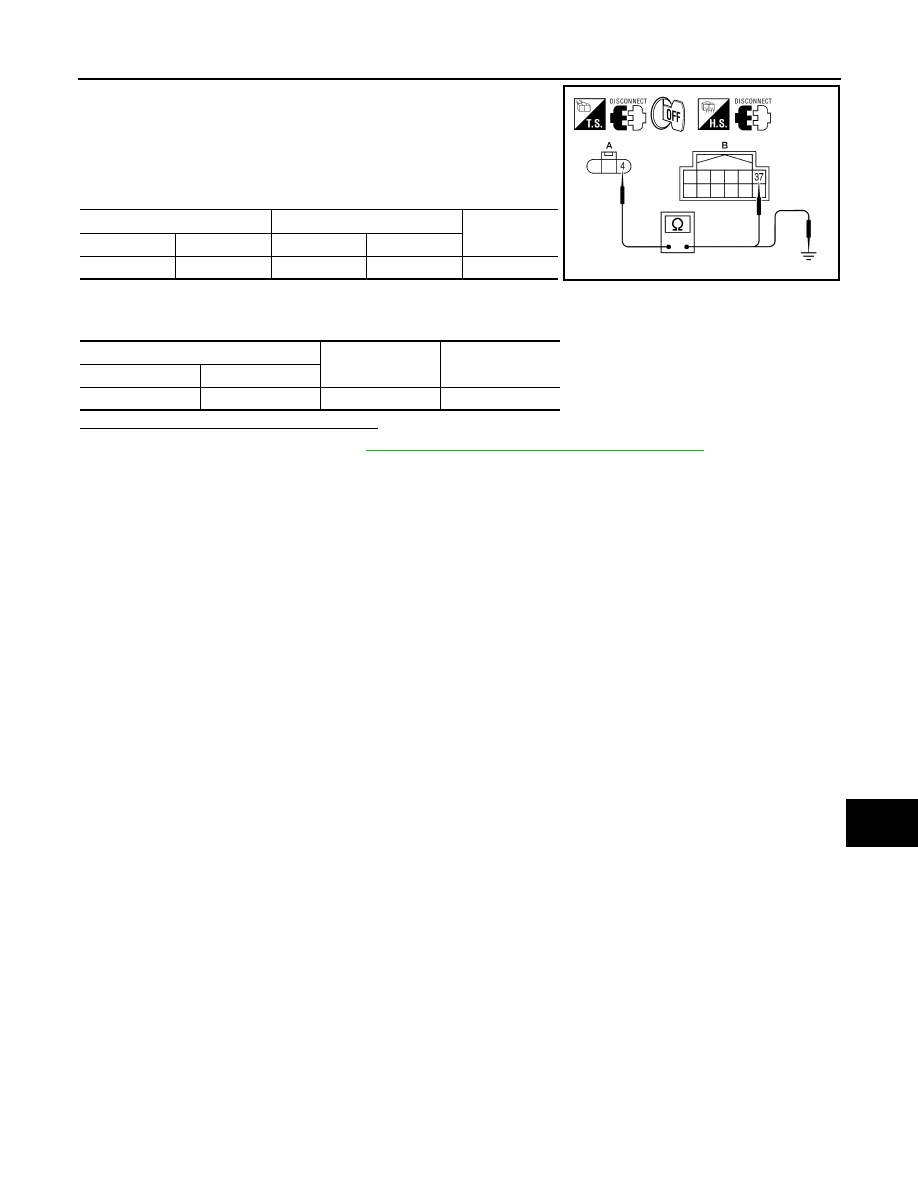

Turn ignition switch OFF.

2.

Disconnect generator connector E205 and IPDM E/R connector

E122.

3.

Check continuity between generator harness connector E205

(A) terminal 4 and IPDM E/R harness connector E122 (B) termi-

nal 37.

4.

Check continuity between generator harness connector E122

(A) terminal 4 and ground.

Are the continuity test results as specified?

YES

>> Replace IPDM E/R. Refer to

PCS-33, "Removal and Installation of IPDM E/R"

.

NO

>> Repair harness or connector between IPDM E/R and generator.

A

B

Continuity

Connector

Terminal

Connector

Terminal

E205

4

E122

37

Yes

A

—

Continuity

Connector

Terminal

E205

4

Ground

No

ALMIA0196ZZ