Content .. 1063 1064 1065 1066 ..

Nissan Frontier D40. Manual - part 1065

TM-158

< FUNCTION DIAGNOSIS >

[5AT: RE5R05A]

DIAGNOSIS SYSTEM (TCM)

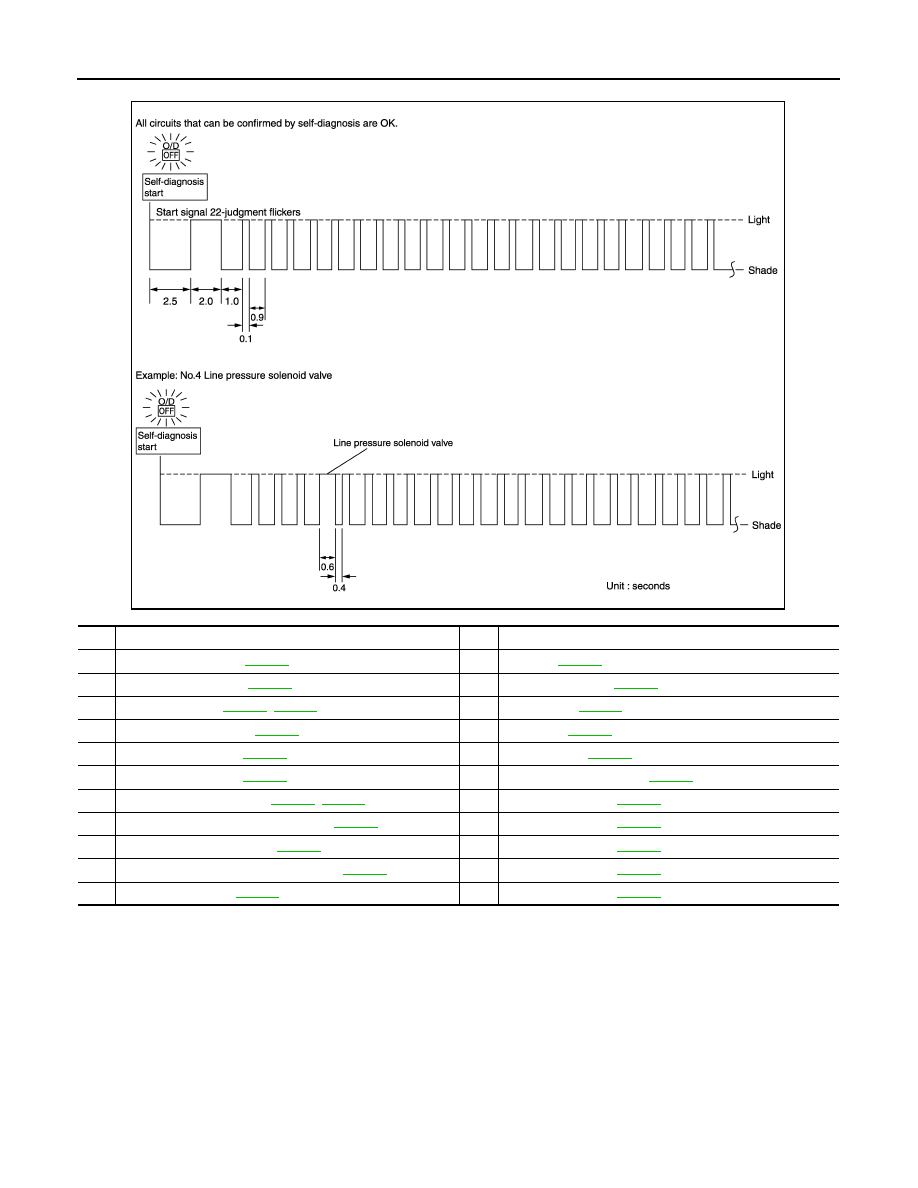

If there is a malfunction, the lamp lights up for the time corresponding to the suspect circuit.

Erase Self-diagnosis

• In order to make it easier to find the cause of hard-to-duplicate malfunctions, malfunction information is

stored into the control unit as necessary during use by the user. This memory is not erased no matter how

many times the ignition switch is turned ON and OFF.

• However, this information is erased by turning ignition switch OFF after executing self-diagnostics or by

erasing the memory using the CONSULT-III.

JSDIA1433GB

No.

Malfunctioning item

No.

Malfunctioning item

1

Output speed sensor

12

Interlock

2

13

1st engine braking

3

Torque converter

14

Starter relay

4

15

TP sensor

5

Input clutch solenoid

16

Engine speed

6

Front brake solenoid

17

7

Low coast brake solenoid

18

1GR incorrect ratio

8

High and low reverse clutch solenoid

19

2GR incorrect ratio

9

20

3GR incorrect ratio

10

Transmission fluid temperature sensor

21

4GR incorrect ratio

11

Input speed sensor

22

5GR incorrect ratio