Nissan Altima L32. Manual - part 669

EM-212

< DISASSEMBLY AND ASSEMBLY >

[VQ35DE]

CYLINDER BLOCK

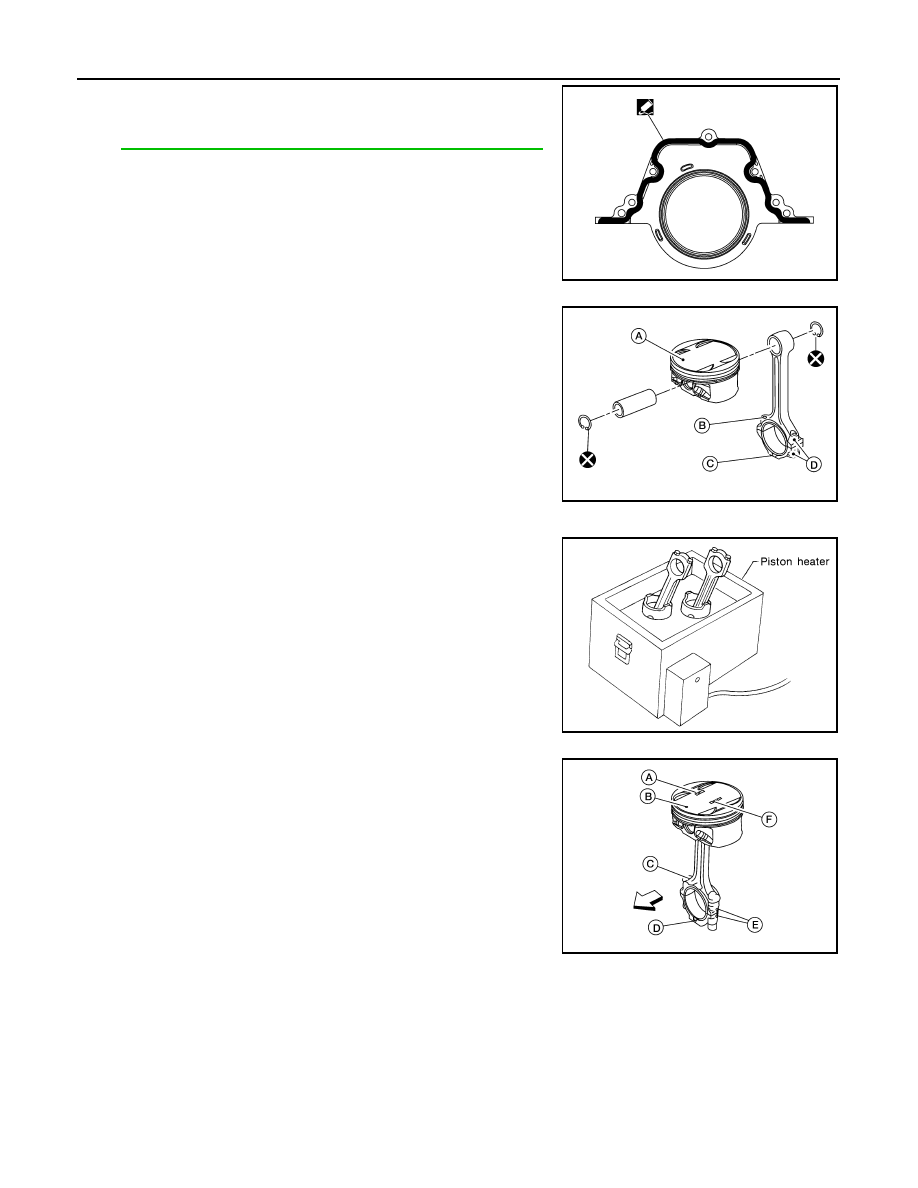

9. Install the rear oil seal retainer.

• Apply sealant to rear oil seal retainer as shown.

Use Genuine Silicone RTV Sealant, or equivalent. Refer to

GI-15, "Recommended Chemical Products and Sealants"

.

10. Install the piston to the connecting rod.

a. Using suitable snap ring pliers, install the snap ring fully into the

pin-groove of the piston rear side.

• Piston front mark (A)

• Oil hole (B)

• Connecting rod front mark (C)

• Cylinder No. (D)

b. Install the piston to the connecting rod.

• Heat the piston until the piston pin can be pushed in by hand

without excess force [approx. 60

° - 70°C (140° to 158°F)].

From the front to the rear, insert the piston pin into the piston

and through the connecting rod.

• Assemble so that the piston front mark (B) on the crown and

the oil hole (C), connecting rod front mark (D) and Cylinder No.

(E) on the are positioned as shown.

-

⇐: Front

- Piston grade number (A)

- Pin grade number (F)

AWBIA0028ZZ

AWBIA0026ZZ

SEM965A

AWBIA0027ZZ