Nissan Altima L32. Manual - part 647

EM-124

< ON-VEHICLE MAINTENANCE >

[VQ35DE]

CAMSHAFT VALVE CLEARANCE

CAMSHAFT VALVE CLEARANCE

Valve Clearance

INFOID:0000000004202156

CHECKING

• Perform inspection as follows after removal, installation or replace-

ment of camshaft or valve related parts, or if there is unusual

engine conditions regarding valve clearance.

Check valve clearance while engine is cold and not running.

1. Remove the air duct with air cleaner case, collectors, hoses,

wires, harnesses, and connectors.

2. Remove the intake manifold collectors.

3. Remove the ignition coils and spark plugs.

4. Remove the rocker covers.

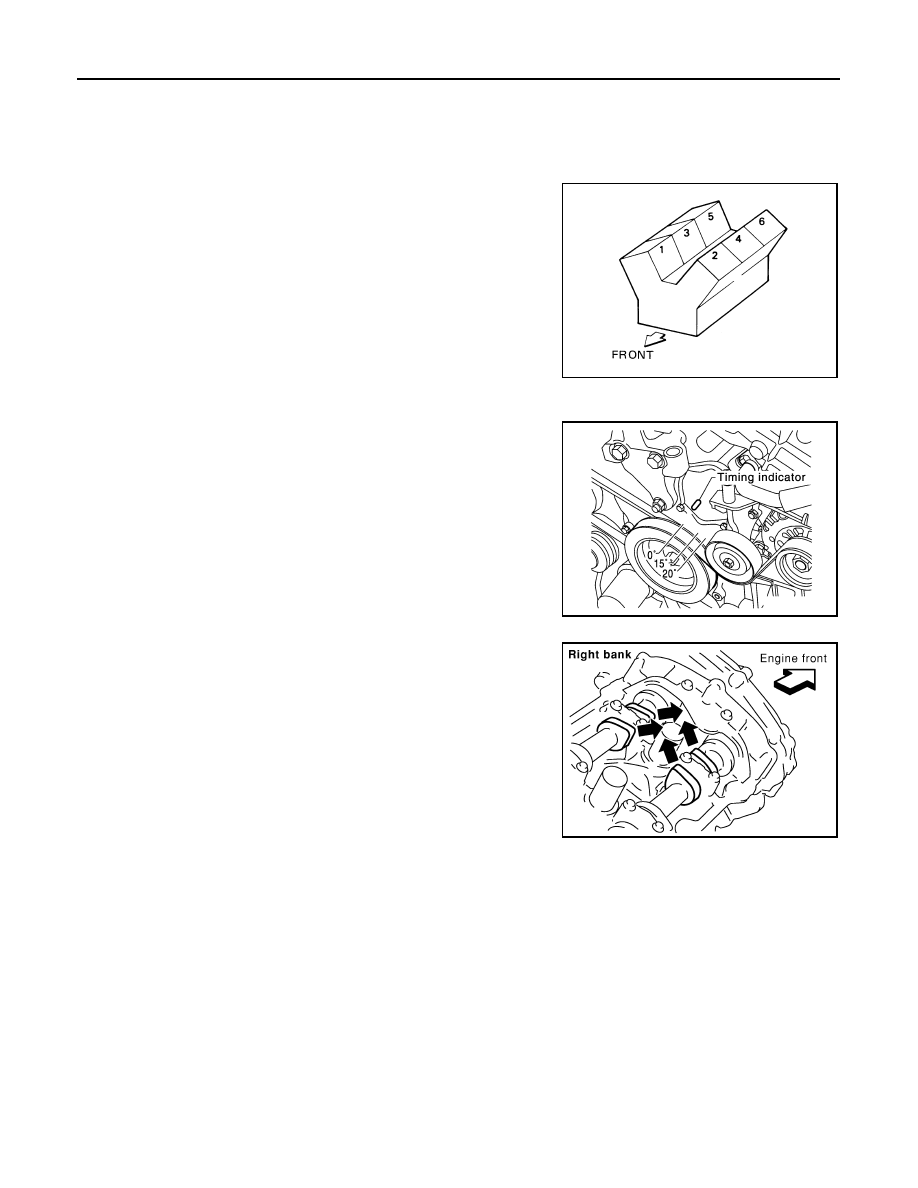

5. Set No.1 cylinder at TDC on its compression stroke.

• Align pointer with TDC mark on crankshaft pulley.

• Check that the valve lifters on No.1 cylinder are loose and

valve lifters on No.4 are tight. If not, turn the crankshaft one full

revolution (360

°) and align as shown.

SEM713A

JMBIA1135GB

SEM418G