Nissan Altima L32. Manual - part 589

COOLING FAN

EC-1477

< COMPONENT DIAGNOSIS >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

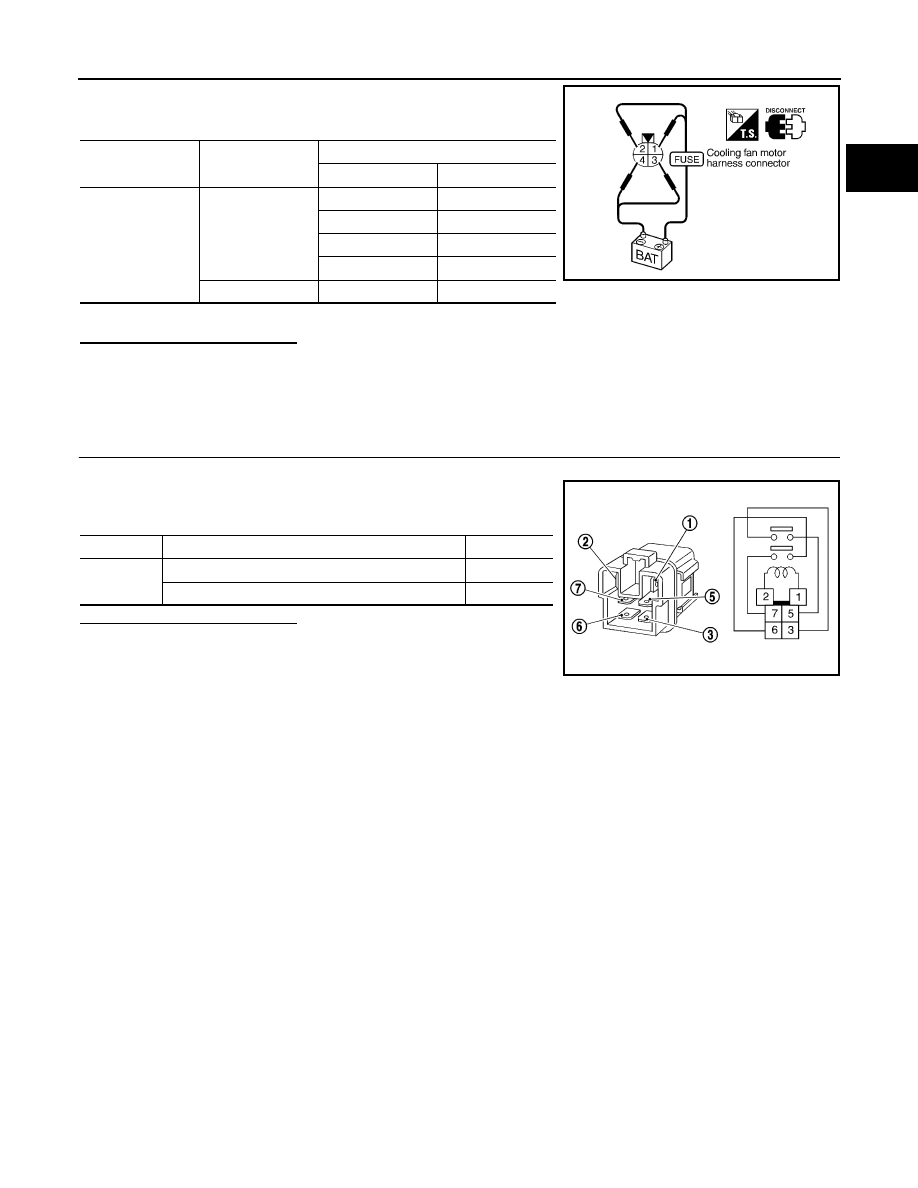

3. Supply cooling fan motor terminals with battery voltage and

check operation.

Check that cooling fan speed of condition B is higher than that of A.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace cooling fan motor.

Component Inspection (Cooling Fan Relay)

INFOID:0000000004362355

1.

CHECK COOLING FAN RELAY

1. Disconnect cooling fan relays -2, -3 harness connectors.

2. Check continuity between cooling fan relay -2, -3 terminals

under the following conditions.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace cooling fan relay.

Condition

Terminals

+

−

Cooling fan motor

A

1

3 and 4

2

3 and 4

1 and 2

3

1 and 2

4

B

1, 2

3, 4

SEF734W

Terminals

Conditions

Continuity

3 and 5

6 and 7

12 V direct current supply between terminals 1 and 2

Existed

No current supply

Not existed

SEF745U