Nissan Altima L32. Manual - part 567

P1217 ENGINE OVER TEMPERATURE

EC-1389

< COMPONENT DIAGNOSIS >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

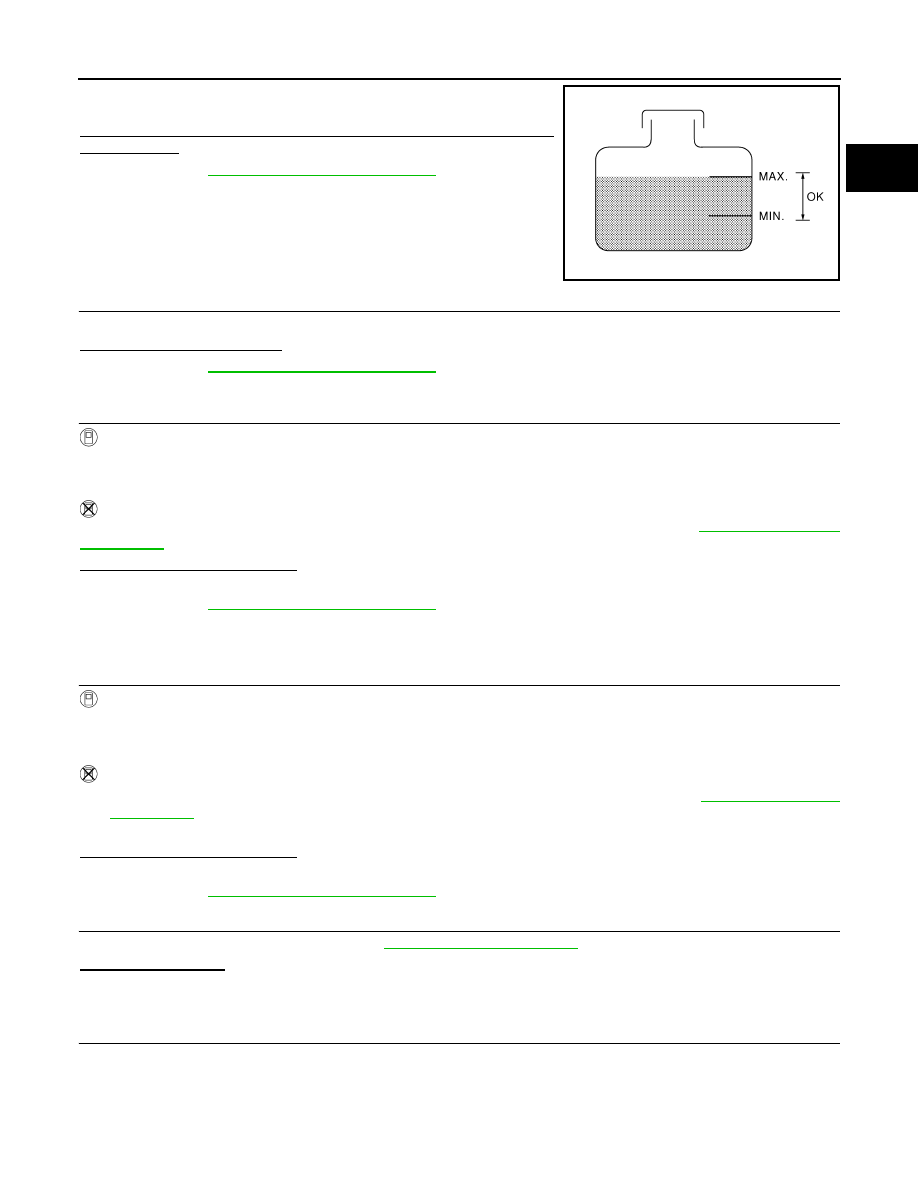

Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

Is the coolant level in the reservoir tank and/or radiator below the

proper range?

YES

>> Go to

EC-1389, "Diagnosis Procedure"

NO

>> GO TO 2.

2.

PERFORM COMPONENT FUNCTION CHECK-II

Confirm whether customer filled the coolant or not.

Did customer fill the coolant?

YES

>> Go to

EC-1389, "Diagnosis Procedure"

NO

>> GO TO 3.

3.

PERFORM COMPONENT FUNCTION CHECK-III

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “COOLING FAN” in “ACTIVE TEST” mode with CONSULT-III.

3. Check that cooling fan motors-1 and -2 operate at each speed (LOW/MID/HI).

Without CONSULT-III

Perform IPDM E/R auto active test and check cooling fan motors operation, refer to

.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Go to

EC-1389, "Diagnosis Procedure"

Diagnosis Procedure

INFOID:0000000004362244

1.

CHECK COOLING FAN OPERATION

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “COOLING FAN” in “ACTIVE TEST” mode with CONSULT-III.

3. Check that cooling fans-1 and -2 operate at each speed (LOW/MID/HI).

Without CONSULT-III

1. Perform IPDM E/R auto active test and check cooling fan motors operation, refer to

.

2. Check that cooling fans-1 and -2 operate at each speed (Low/Middle/High).

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Go to

EC-1473, "Diagnosis Procedure"

2.

CHECK COOLING SYSTEM FOR LEAKAGE-I

Check cooling system for leakage. Refer to

.

Is leakage detected?

YES

>> GO TO 3.

NO

>> GO TO 4.

3.

CHECK COOLING SYSTEM FOR LEAKAGE-II

Check the following for leakage.

• Hose

• Radiator

• Water pump

SEF621W