Nissan Altima L32. Manual - part 441

P1550 BATTERY CURRENT SENSOR

EC-885

< COMPONENT DIAGNOSIS >

[QR25DE EXCEPT FOR CALIFORNIA]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

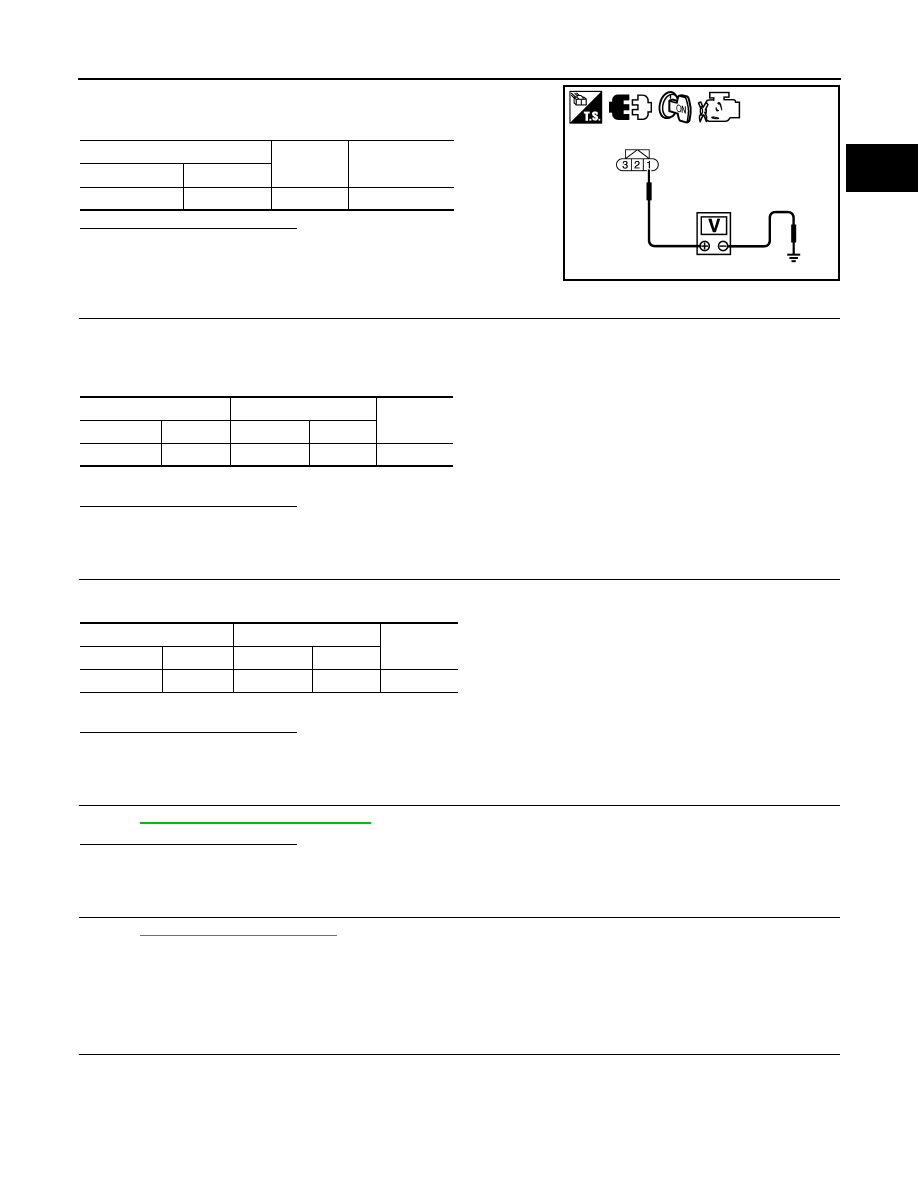

3. Check the voltage between battery current sensor harness con-

nector and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair open circuit or sort to ground or short to power in

harness or connectors.

3.

CHECK BATTERY CURRENT SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between battery current sensor harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair open circuit or sort to ground or short to power in harness or connectors.

4.

CHECK BATTERY CURRENT SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between battery current sensor harness connector and ECM harness connector.

2. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair open circuit or sort to ground or short to power in harness or connectors.

5.

CHECK BATTERY CURRENT SENSOR

EC-885, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Replace battery negative cable assembly.

6.

CHECK INTERMITTENT INCIDENT

GI-42, "Intermittent Incident"

.

>> INSPECTION END

Component Inspection

INFOID:0000000004349858

1.

CHECK BATTERY CURRENT SENSOR

1. Reconnect harness connectors disconnected.

Battery current sensor

Ground

Voltage

Connector

Terminal

F5

1

Ground

Approx. 5V

JMBIA1602ZZ

Battery current sensor

ECM

Continuity

Connector

Terminal

Connector

Terminal

F5

2

F13

44

Existed

Battery current sensor

ECM

Continuity

Connector

Terminal

Connector

Terminal

F5

3

F13

42

Existed