Nissan Altima L32. Manual - part 425

P0448 EVAP CANISTER VENT CONTROL VALVE

EC-821

< COMPONENT DIAGNOSIS >

[QR25DE EXCEPT FOR CALIFORNIA]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

4. Check air passage continuity and operation delay time.

Make sure new O-ring is installed properly.

Operation takes less than 1 second.

Without CONSULT-III

Check air passage continuity and operation delay time under the fol-

lowing conditions.

Make sure new O-ring is installed properly.

Operation takes less than 1 second.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace EVAP canister vent control valve

3.

CHECK EVAP CANISTER VENT CONTROL VALVE-III

With CONSULT-III

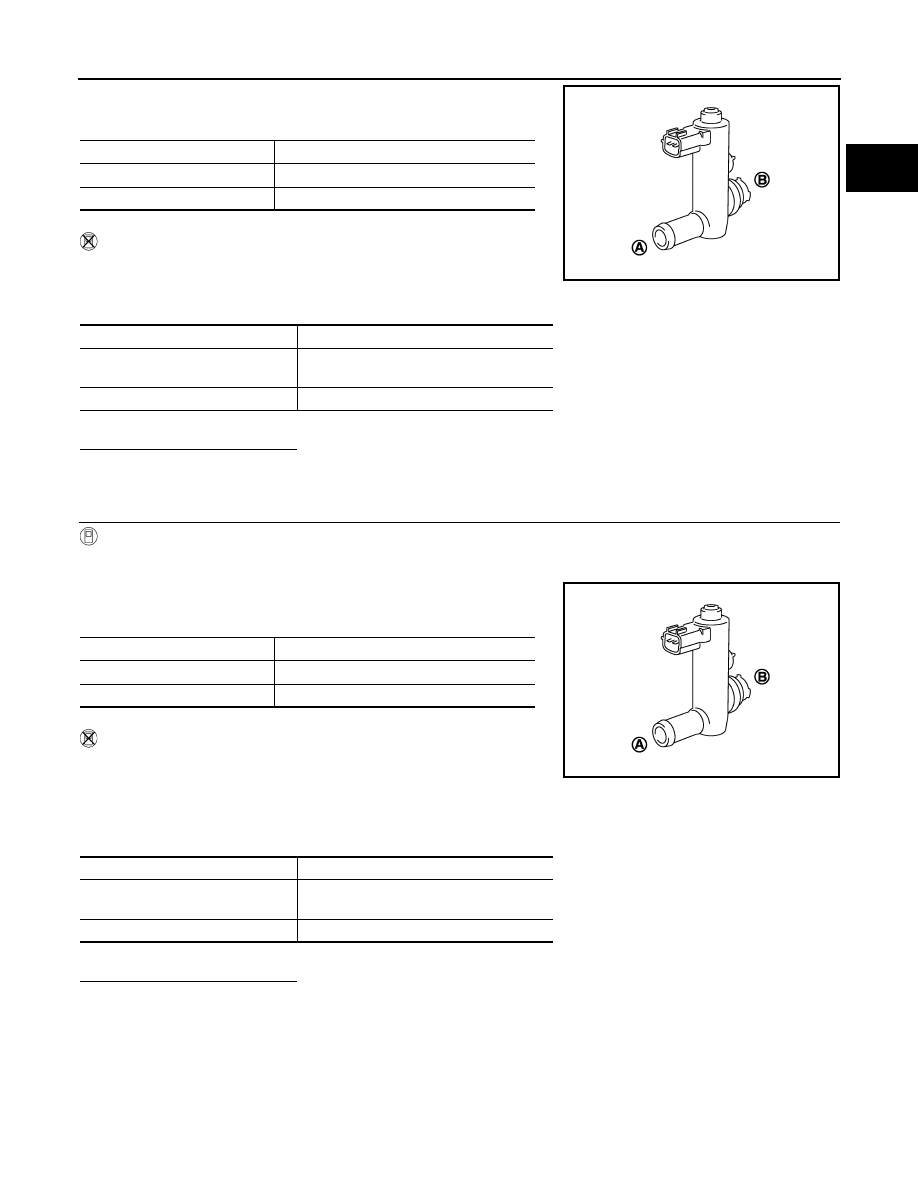

1. Clean the air passage [portion (A) to (B)] of EVAP canister vent control valve using an air blower.

2. Perform “VENT CONTROL/V” in “ACTIVE TEST” mode.

3. Check air passage continuity and operation delay time.

Make sure new O-ring is installed properly.

Operation takes less than 1 second.

Without CONSULT-III

1. Clean the air passage [portion (A) to (B)] of EVAP canister vent

control valve using an air blower.

2. Check air passage continuity and operation delay time under the

following conditions.

Make sure new O-ring is installed properly.

Operation takes less than 1 second.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> GO TO 3.

Condition VENT CONTROL/V

Air passage continuity between (A) and (B)

ON

Not existed

OFF

Existed

Condition

Air passage continuity between (A) and (B)

12V direct current supply between

terminals (1) and (2)

Not existed

OFF

Existed

JMBIA0169ZZ

Condition VENT CONTROL/V

Air passage continuity between (A) and (B)

ON

Not existed

OFF

Existed

Condition

Air passage continuity between (A) and (B)

12V direct current supply between

terminals (1) and (2)

Not existed

OFF

Existed

JMBIA0169ZZ