Nissan Altima L32. Manual - part 416

P0335 CKP SENSOR (POS)

EC-785

< COMPONENT DIAGNOSIS >

[QR25DE EXCEPT FOR CALIFORNIA]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

5.

CHECK COMPONENTS

Check the following.

• Refrigerant pressure sensor (Refer to

.)

• EVAP control system pressure sensor (Refer to

EC-824, "Component Inspection"

.)

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Replace malfunctioning components.

6.

CHECK APP SENSOR

EC-926, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 12.

NO

>> GO TO 7.

7.

REPLACE ACCELERATOR PEDAL ASSEMBLY

1. Replace accelerator pedal assembly.

2. Go to

EC-926, "Special Repair Requirement"

.

>> INSPECTION END

8.

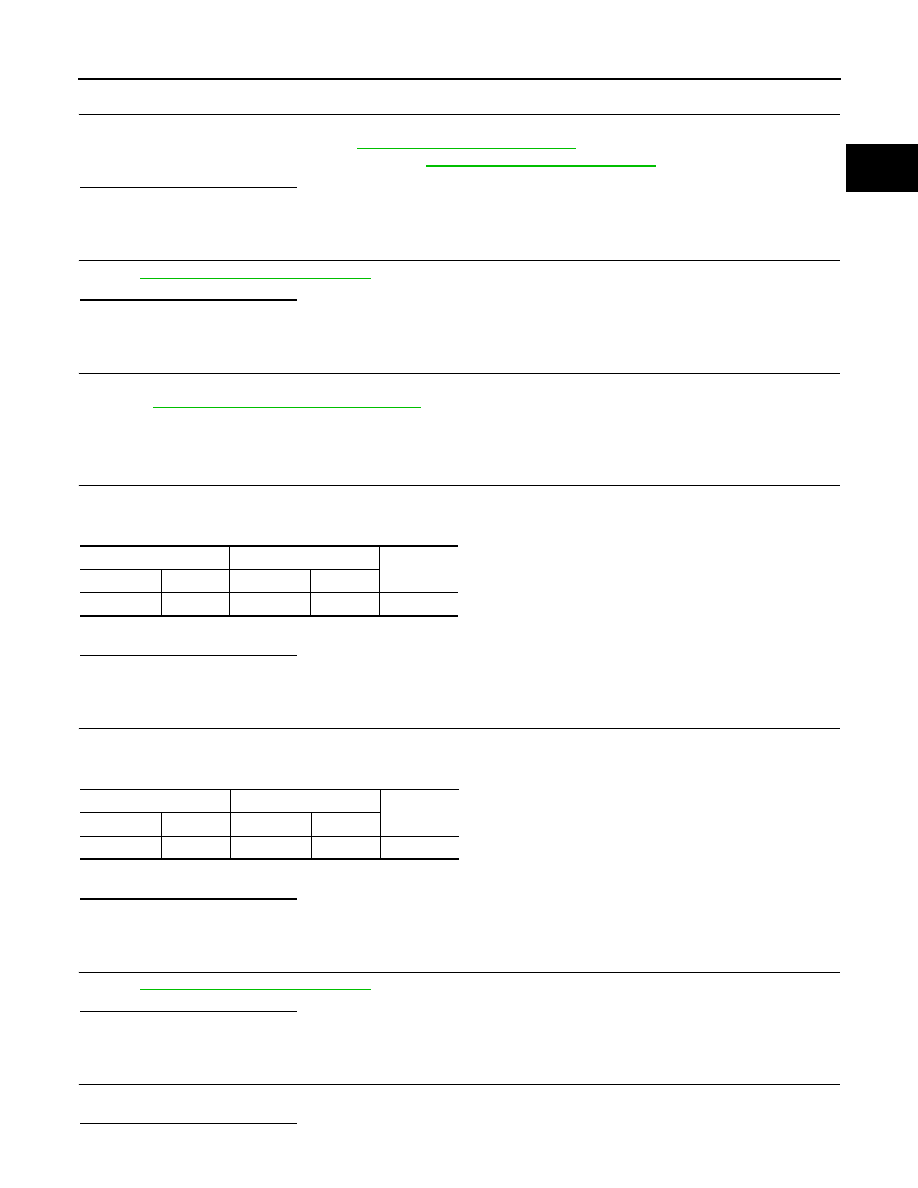

CHECK CKP SENSOR (POS) GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check the continuity between CKP sensor (POS) harness connector and ECM harness connector.

3. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

9.

CHECK CKP SENSOR (POS) INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check the continuity between CKP sensor (POS) harness connector and ECM harness connector.

3. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

10.

CHECK CRANKSHAFT POSITION SENSOR (POS)

EC-786, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 11.

NO

>> Replace crankshaft position sensor (POS).

11.

CHECK GEAR TOOTH

Visually check for chipping signal plate gear tooth.

Is the inspection result normal?

CKP sensor (POS)

ECM

Continuity

Connector

Terminal

Connector

Terminal

F30

2

F13

60

Existed

CKP sensor (POS)

ECM

Continuity

Connector

Terminal

Connector

Terminal

F30

3

F13

65

Existed