Nissan Altima L32. Manual - part 286

P0182, P0183 FTT SENSOR

EC-265

< COMPONENT DIAGNOSIS >

[QR25DE FOR CALIFORNIA]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0182, P0183 FTT SENSOR

Description

INFOID:0000000004349301

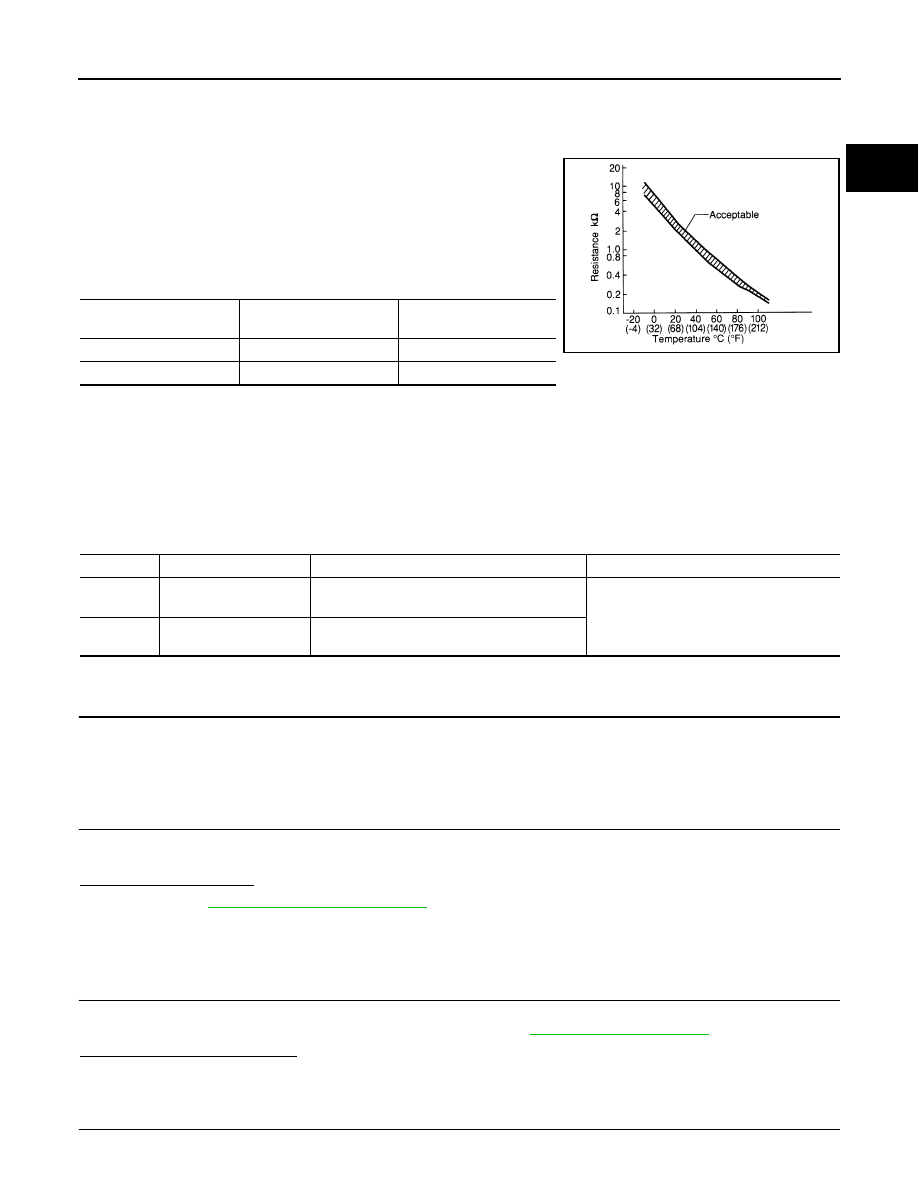

The fuel tank temperature sensor is used to detect the fuel tempera-

ture inside the fuel tank. The sensor modifies a voltage signal from

the ECM. The modified signal returns to the ECM as the fuel temper-

ature input. The sensor uses a thermistor which is sensitive to the

change in temperature. The electrical resistance of the thermistor

decreases as temperature increases.

<Reference data>

*: These data are reference values and are measured between ECM terminal 95 (Fuel tank temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in damage to the ECM's transis-

tor. Use a ground other than ECM terminals, such as the ground.

DTC Logic

INFOID:0000000004349302

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON and wait at least 5 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000004349303

1.

CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E9. Refer to Ground Inspection in

.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ground connection.

2.

CHECK FUEL TANK TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

Fluid temperature

°C (°F)]

Voltage*

(V)

Resistance

(k

Ω

20 (68)

3.5

2.3 - 2.7

50 (122)

2.2

0.79 - 0.90

SEF012P

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0182

Fuel tank temperature

sensor circuit low input

An excessively low voltage from the sensor is

sent to ECM.

• Harness or connectors

(The sensor circuit is open or shorted.)

• Fuel tank temperature sensor

P0183

Fuel tank temperature

sensor circuit high input

An excessively high voltage from the sensor is

sent to ECM.