Content .. 1431 1432 1433 1434 ..

Nissan Altima L32. Manual - part 1433

TM-76

< DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F52A]

FINAL DRIVE

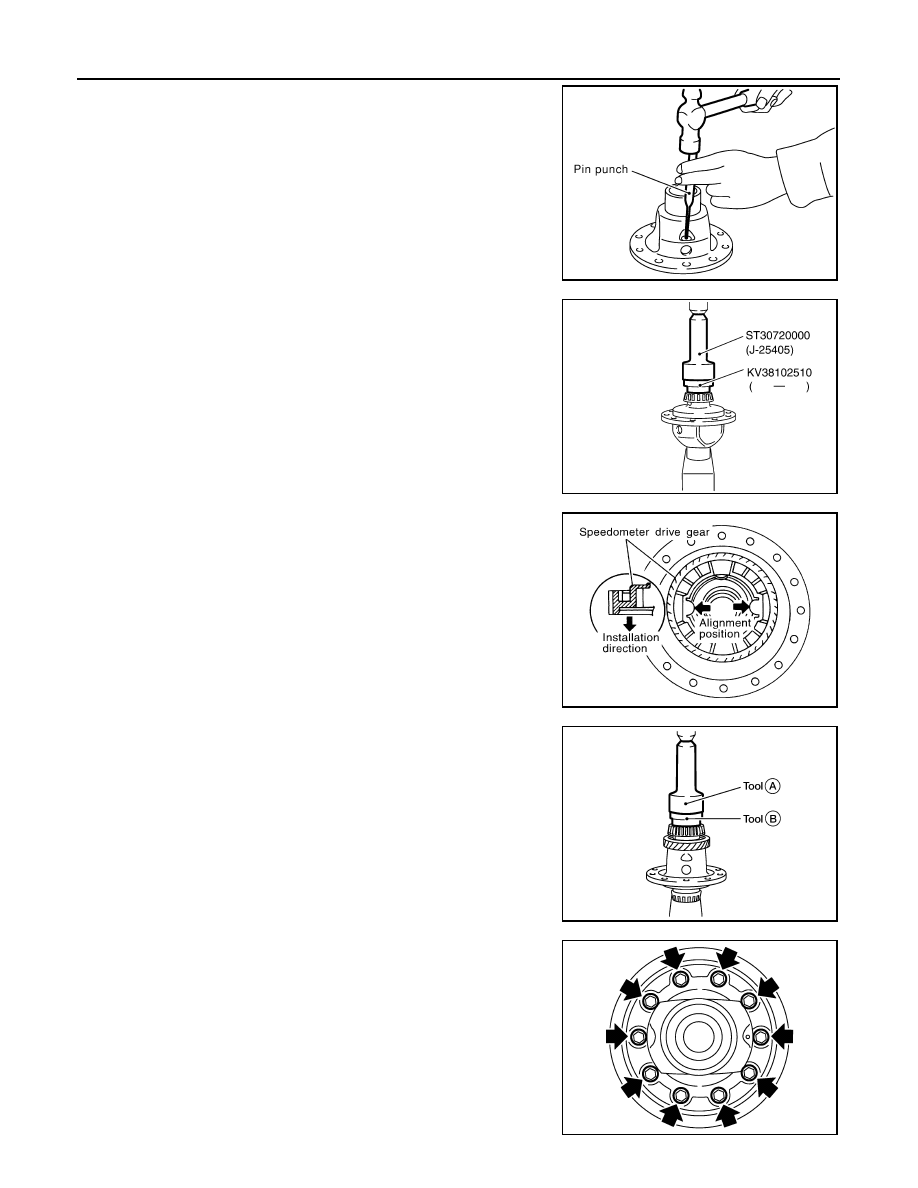

6. Install retaining pin into pinion mate shaft using suitable tool.

CAUTION:

Do not reuse retaining pin.

7. Press in differential side bearing (transaxle case side) to differ-

ential case using Tools.

CAUTION:

Replace differential side bearing and differential side bear-

ing outer race as a set.

8. Align and install speedometer drive gear onto differential case.

9. Press in differential side bearing (clutch housing side) to differ-

ential case using Tools (A) and (B).

CAUTION:

• Do not reuse differential side bearing and differential side

bearing outer race.

• Replace differential side bearing and differential side

bearing outer race as a set.

10. Install final gear into differential case and tighten final gear bolts

to the specified torque.

SCIA0908E

Tool numbers

: ST30720000 (J-25405)

: KV38102510 ( — )

PCIB0952E

SMT842D

Tool numbers

A: ST30720000 (J-25405)

B: KV38102510 ( — )

WCIA0305E

SCIA0912E