Nissan Altima L32. Manual - part 19

AV-68

< SYMPTOM DIAGNOSIS >

[BASE AUDIO]

NORMAL OPERATING CONDITION

NORMAL OPERATING CONDITION

Description

INFOID:0000000004206399

The majority of the audio concerns are the result of outside causes (bad CD, electromagnetic interference,

etc.).

NOISE

The following noise results from variations in field strength, such as fading noise and multi-path noise, or

external noise from trains and other sources. It is not a malfunction.

• Fading noise: This noise occurs because of variations in the field strength in a narrow range due to moun-

tains or buildings blocking the signal.

• Multi-path noise: This noise results from the waves sent directly from the broadcast station arriving at the

antenna at a different time from the waves which reflect off mountains or buildings.

The vehicle itself can be a source of noise if noise prevention parts or electrical equipment is malfunctioning.

Check if noise is caused and/or changed by engine speed, ignition switch turned to each position, and opera-

tion of each piece of electrical equipment, and determine the cause.

NOTE:

The source of the noise can be found easily by listening to the noise while removing the fuses of electrical

components, one by one.

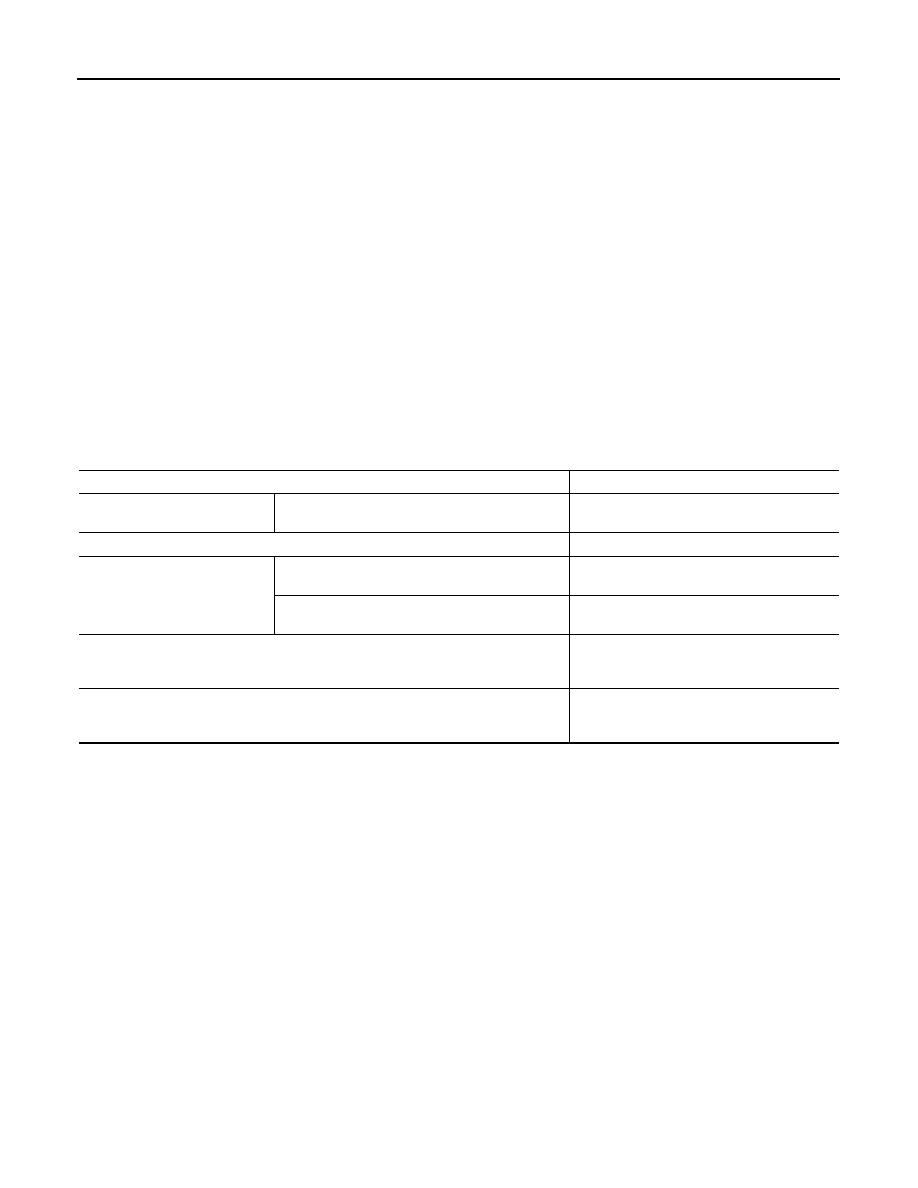

Type of Noise and Possible Cause

Occurrence condition

Possible cause

Occurs only when engine is ON.

A continuous growling noise occurs. The speed of

the noise varies with changes in the engine speed.

• Ignition components

The occurrence of the noise is linked with the operation of the fuel pump.

• Fuel pump condenser

Noise only occurs when various

electrical components are oper-

ating.

A cracking or snapping sound occurs with the op-

eration of various switches.

• Relay malfunction, audio unit malfunction

The noise occurs when various motors are operat-

ing.

• Motor case ground

• Motor

The noise occurs constantly, not just under certain conditions.

• Rear defogger coil malfunction

• Open circuit in printed heater

• Poor ground of antenna feeder line

A cracking or snapping sound occurs while the vehicle is being driven, especially when

it is vibrating excessively.

• Ground wire of body parts

• Ground due to improper part installation

• Wiring connections or a short circuit