Nissan Titan A60. Manual - part 478

ENGINE UNIT

EM-97

< UNIT DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

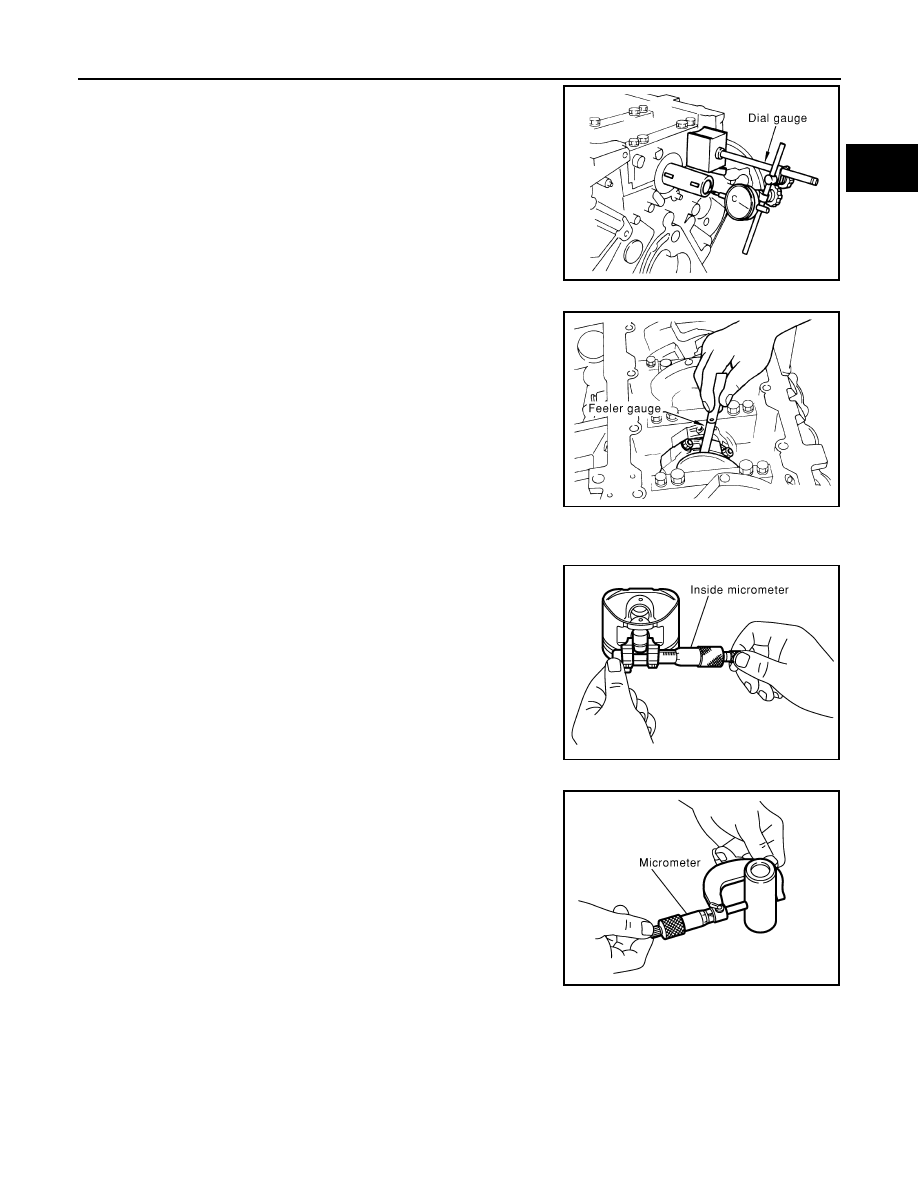

• Move the crankshaft fully forward and backward and measure the

clearance between the thrust bearings and crankshaft arm using

suitable tool.

• If measured value exceeds the repair limit, replace the thrust bear-

ings, and measure again. If it still exceeds the repair limit, replace

crankshaft also.

CONNECTING ROD SIDE CLEARANCE

• Measure side clearance between the connecting rod and crank-

shaft arm using suitable tool.

• If measured value exceeds the repair limit, replace the connecting

rod bearings, and measure again. If it still exceeds the repair limit,

replace the crankshaft also.

PISTON AND PISTON PIN CLEARANCE

Piston Pin Hole Diameter

• Measure diameter of piston pin hole using suitable tool.

Piston Pin Diameter

• Measure diameter of piston pin using suitable tool.

Piston and Piston Pin Clearance

Standard

: 0.10 - 0.26 mm (0.0039 - 0.0102 in)

Limit

: 0.30 mm (0.0118 in)

PBIC0114E

Standard

: 0.20 - 0.40 mm (0.0079 - 0.0157 in)

Limit

: 0.40 mm (0.0157 in)

PBIC0115E

Standard

: 21.993 - 21.999 mm (0.8659 - 0.8661 in)

PBIC0116E

Standard

: 21.989 - 21.995 mm (0.8657 - 0.8659 in)

PBIC0117E