Nissan Titan A60. Manual - part 458

SPARK PLUG

EM-17

< PERIODIC MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

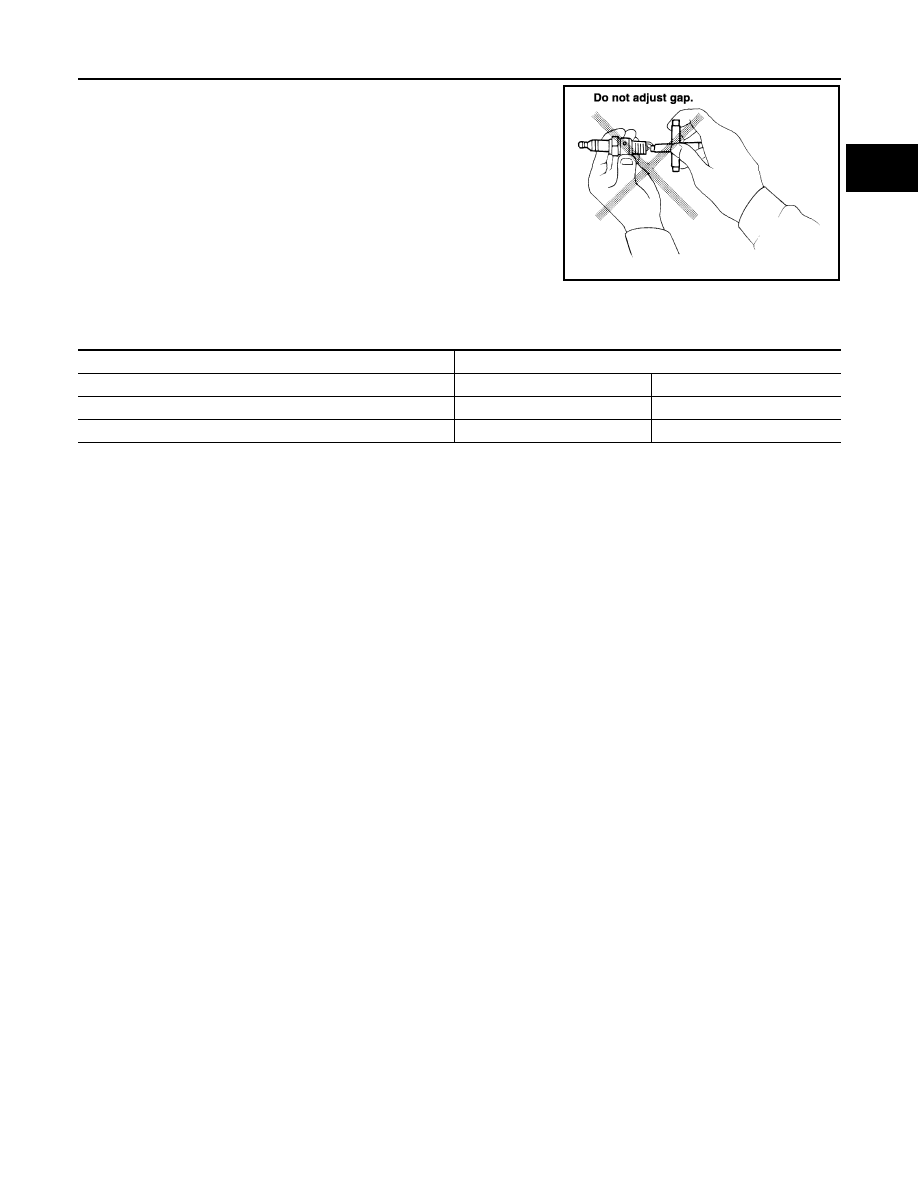

• Checking and adjusting plug gap is not required between change

intervals.

INSTALLATION

Installation is in the reverse order of removal.

Spark Plug Types

*: Always check with the Parts Department for the latest parts information.

CAUTION:

Do not drop or shock spark plug.

SMA806CA

Make

NGK

Model

Standard model

FFV model

Standard type*

DILFR5A-11

DILFR5A-11D

Gap (Nominal)

1.1 mm (0.043 in)

1.1 mm (0.043)