Nissan Titan A60. Manual - part 329

DIFFERENTIAL LOCK POSITION SWITCH

DLN-255

< REMOVAL AND INSTALLATION >

[REAR FINAL DRIVE: M226 (ELD) ]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

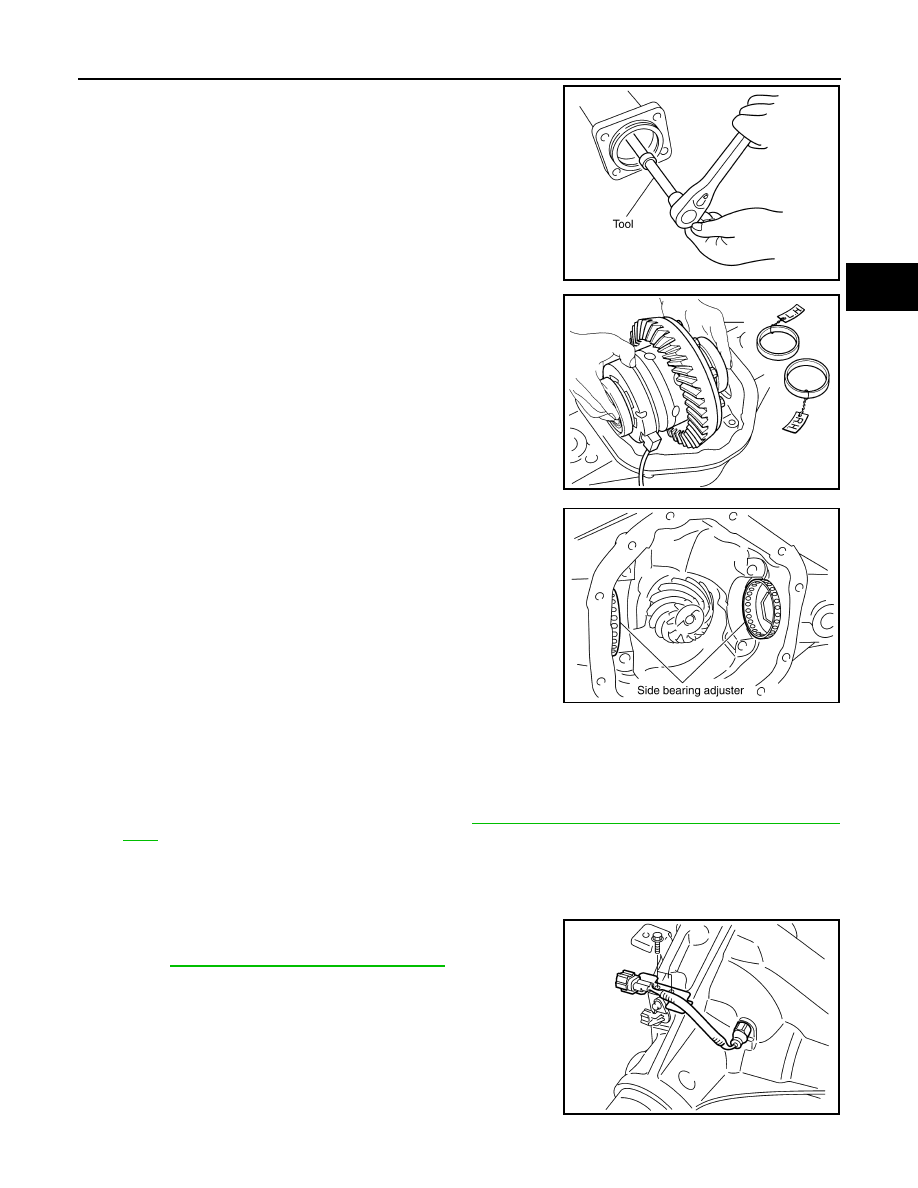

9. Loosen the side bearing adjusters using Tool.

10. Remove the differential case assembly. Keep side bearing outer

races together with inner races, do not mix them up. Also, keep

side bearing adjusters together with bearing.

11. Remove side bearing adjusters from gear carrier.

12. Remove bracket for the differential lock position switch connector and bolts.

13. Remove differential lock position switch.

INSTALLATION

1. Apply sealant to threads of differential lock position switch.

• Use Genuine Silicone RTV or equivalent. Refer to

GI-15, "Recommended Chemical Products and Seal-

CAUTION:

Remove old sealant adhering to gear carrier and differential lock position switch. Also remove any

moisture, oil, or foreign material adhering to application and gear carrier and differential lock posi-

tion switch.

2. Install differential lock position switch on gear carrier and tighten

differential lock position switch bolts with the specified torque.

DLN-263, "Disassembly and Assembly"

Tool number

:

—

(C - 4164)

PDIA0337E

SDIA2588E

PDIA0381E

SDIA2633E