Nissan Titan A60. Manual - part 311

FRONT FINAL DRIVE

DLN-183

< UNIT DISASSEMBLY AND ASSEMBLY >

[FRONT FINAL DRIVE: M205]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

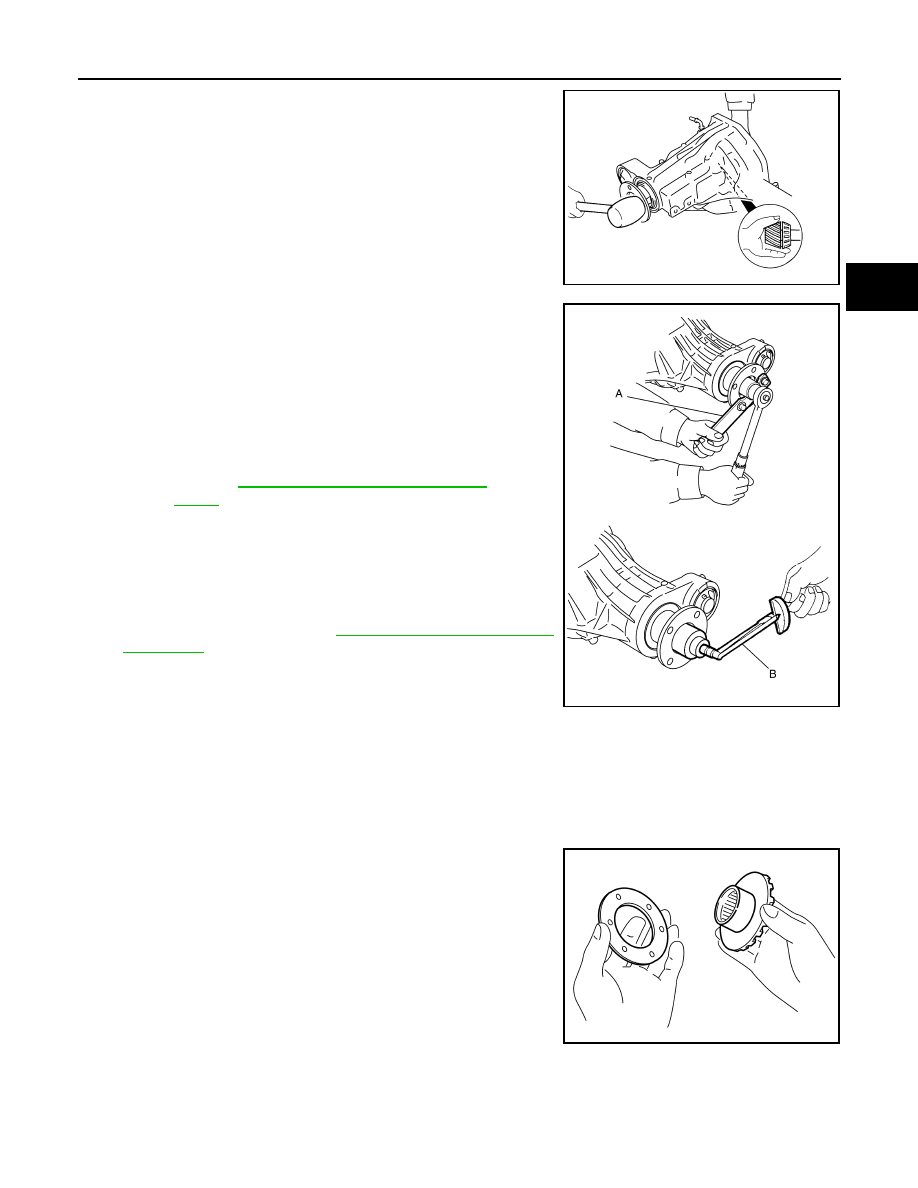

9. Install the companion flange to the drive pinion while aligning the

matching marks. Tap the companion flange until fully seated

using suitable tool.

10. Apply anti-corrosive oil to the threads of the drive pinion and the

seating surface of the new drive pinion lock nut. Then adjust the

drive pinion lock nut tightening torque using suitable tool (A),

and check the drive pinion bearing preload torque using Tool

(B).

CAUTION:

• Do not reuse drive pinion lock nut.

• Apply anti-corrosive oil to the threads of the drive pinion

and the seating surface of the new drive pinion lock nut.

• Adjust the drive pinion lock nut tightening torque to the

lower limit first. Do not exceed the drive pinion lock nut

.

• If the drive pinion bearing preload torque exceeds the

specified value, replace collapsible spacer and tighten it

again to adjust. Do not loosen drive pinion lock nut to

adjust the drive pinion bearing preload torque.

• After adjustment, rotate drive pinion back and forth 2 to 3 times to check for unusual noise, rota-

tion malfunction, and other malfunctions.

11. Check companion flange runout.

12. Install the differential case assembly.

Differential Assembly

1. Install side gear thrust washers with the same thickness as the

ones installed prior to disassembly, or reinstall the old ones on

the side gears.

SDIA2266E

Tool number

B: ST3127S000 (J-25765-A)

Drive pinion bearing preload torque:

Refer to

DLN-187, "Inspection and Adjust-

WDIA0382E

SDIA0193J