Nissan Titan A60. Manual - part 258

DLK-106

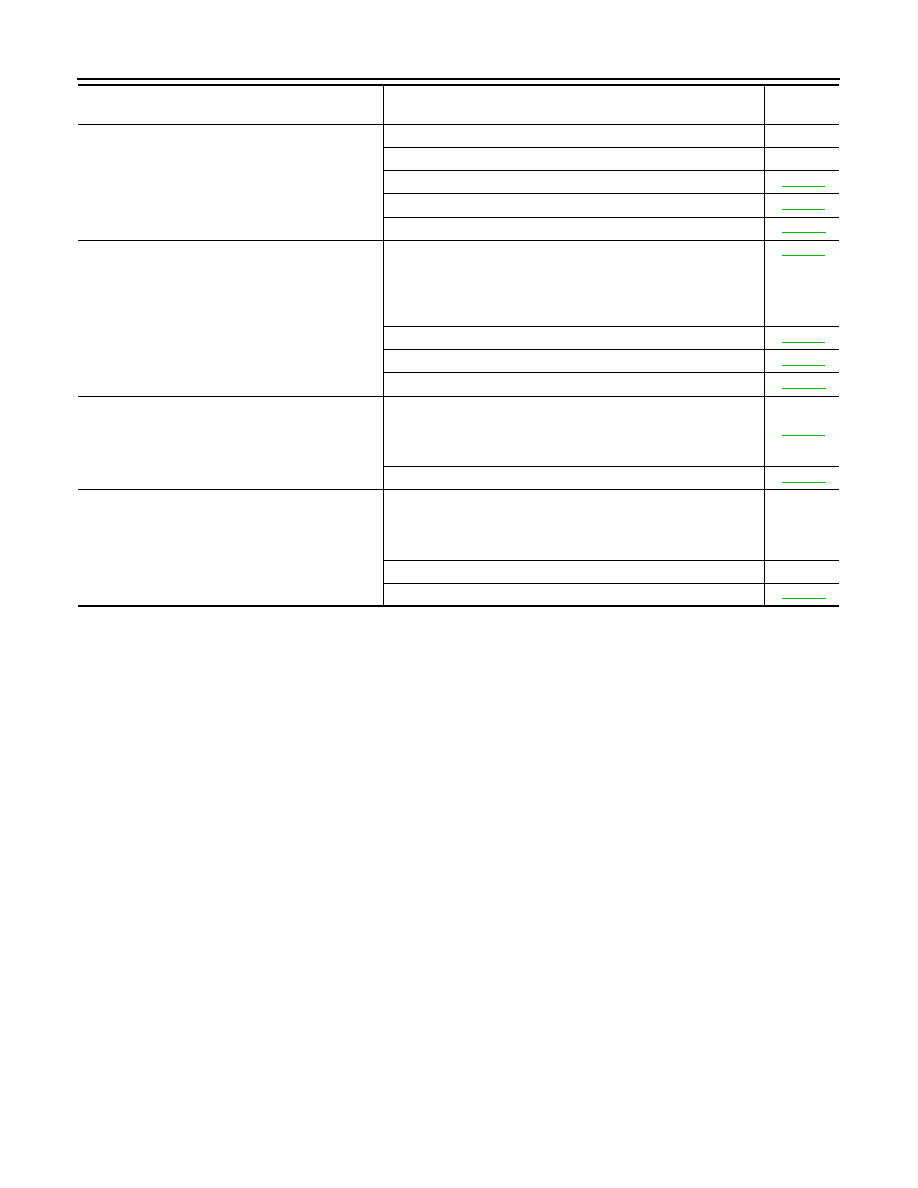

< SYMPTOM DIAGNOSIS >

REMOTE KEYLESS ENTRY SYSTEM

2. Ignition keyhole illumination operation check

—

3. Step lamp operation check

—

4a. Door switch check (king cab)

4b. Door switch check (crew cab)

5. Replace BCM.

Panic alarm (horn and headlamp) does not activate

when panic alarm button is continuously pressed.

1. Keyfob battery and function check (use Remote Keyless Entry

Tester J-43241)

NOTE:

If the result of keyfob function check is OK, keyfob is not malfunc-

tioning.

2a. Key switch check (column shift)

2b. Key switch and key lock solenoid (key switch) check (floor shift)

3. Replace BCM.

Auto door lock operation does not activate properly.

(All other remote keyless entry functions OK.)

1. Check auto door lock operation mode with CONSULT-III

NOTE:

Auto door lock operation mode can be changed.

First check the auto door lock operation mode setting.

2. Replace BCM.

Keyless power window down (open) operation does

not activate properly.

(All other remote keyless entry functions OK.)

1. Check power window down operation mode with CONSULT-III

NOTE:

Power window down operation mode can be changed.

First check the power window down operation mode setting.

—

2. Check power window function with switch

—

3. Replace BCM.

Symptom

Diagnoses/service procedure

Reference

page