Nissan Titan A60. Manual - part 210

CHG

CHARGING SYSTEM PRELIMINARY INSPECTION

CHG-7

< DTC/CIRCUIT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

DTC/CIRCUIT DIAGNOSIS

CHARGING SYSTEM PRELIMINARY INSPECTION

Inspection Procedure

INFOID:0000000006161762

1.

CHECK BATTERY TERMINALS CONNECTION

Check if battery terminals are clean and tight.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair battery terminals connection.

2.

CHECK FUSE

Check for blown fuse and fusible link.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Be sure to eliminate cause of malfunction before installing new fuse or fusible link.

3.

CHECK GENERATOR GROUND TERMINAL CONNECTION

Verify connector E206 terminal 5 (generator ground harness) is clean and tight.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair connection.

4.

CHECK DRIVE BELT TENSION

Check drive belt tension. Refer to

.

Is the inspection result normal?

YES

>> Inspection End.

NO

>> Repair as needed.

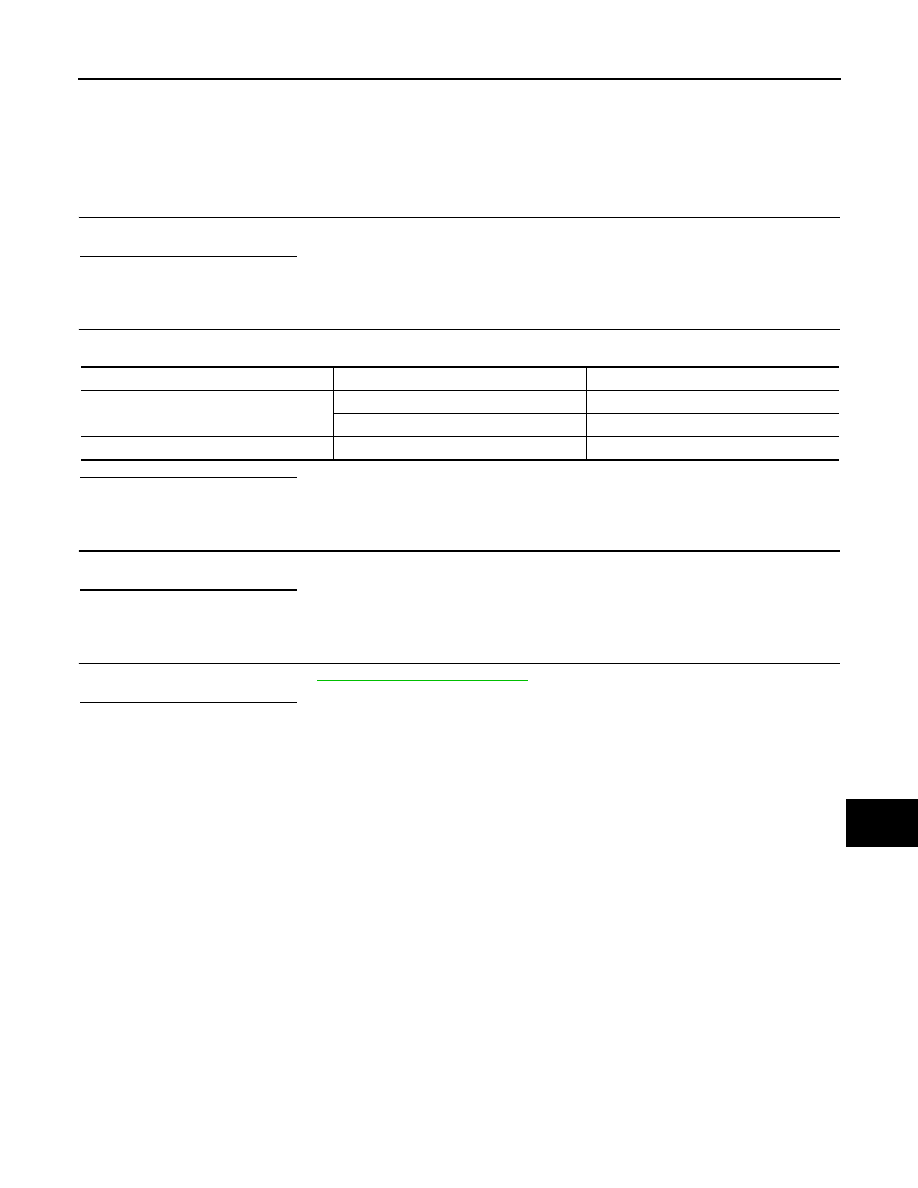

Unit

Power source (Power supply terminals)

Fuse or Fusible Link

Generator

Battery (terminal 3)

Fuse 30

Battery (terminal 1)

Fusible Link A

Combination meter

Ignition switch ON (terminal 2)

Fuse 14