Nissan Versa Note. Manual - part 797

TM-68

< SYSTEM DESCRIPTION >

[CVT: RE0F11A]

STRUCTURE AND OPERATION

STRUCTURE AND OPERATION

TRANSAXLE

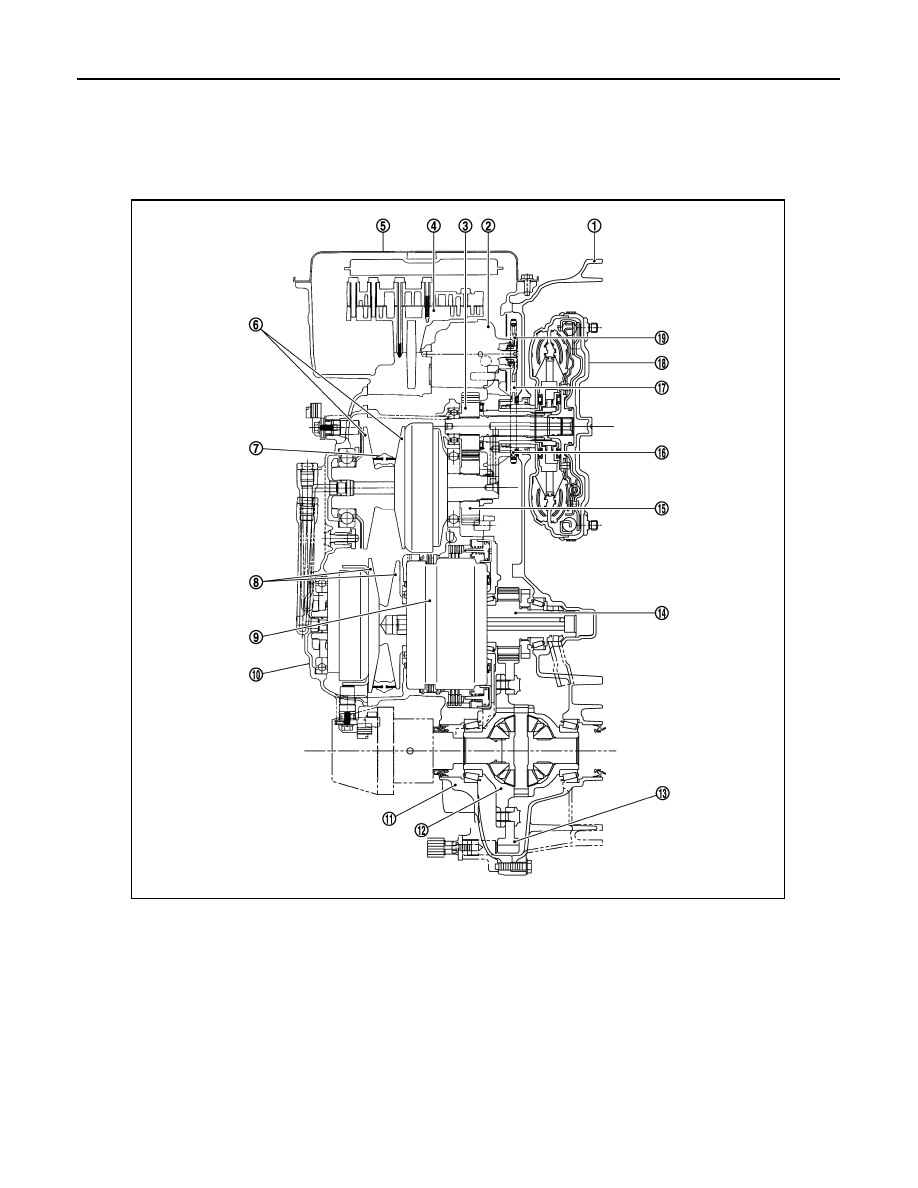

TRANSAXLE : Cross-Sectional View

INFOID:0000000009019604

TRANSAXLE : Transaxle Mechanism

INFOID:0000000009019605

BELT & PULLEY

1.

Converter housing

2.

Oil pump

3.

Counter drive gear

4.

Control valve

5.

Oil pan

6.

Primary pulley

7.

Steel belt

8.

Secondary pulley

9.

Planetary gear (auxiliary gearbox)

10.

Side cover

11.

Transaxle case

12.

Differential case

13.

Final gear

14.

Reduction gear

15.

Counter driven gear

16.

Drive sprocket

17.

Oil pump chain

18.

Torque converter

19.

Driven sprocket

JSDIA1777ZZ