Nissan Versa Note. Manual - part 460

FRONT COIL SPRING AND STRUT

FSU-17

< UNIT DISASSEMBLY AND ASSEMBLY >

C

D

F

G

H

I

J

K

L

M

A

B

FSU

N

O

P

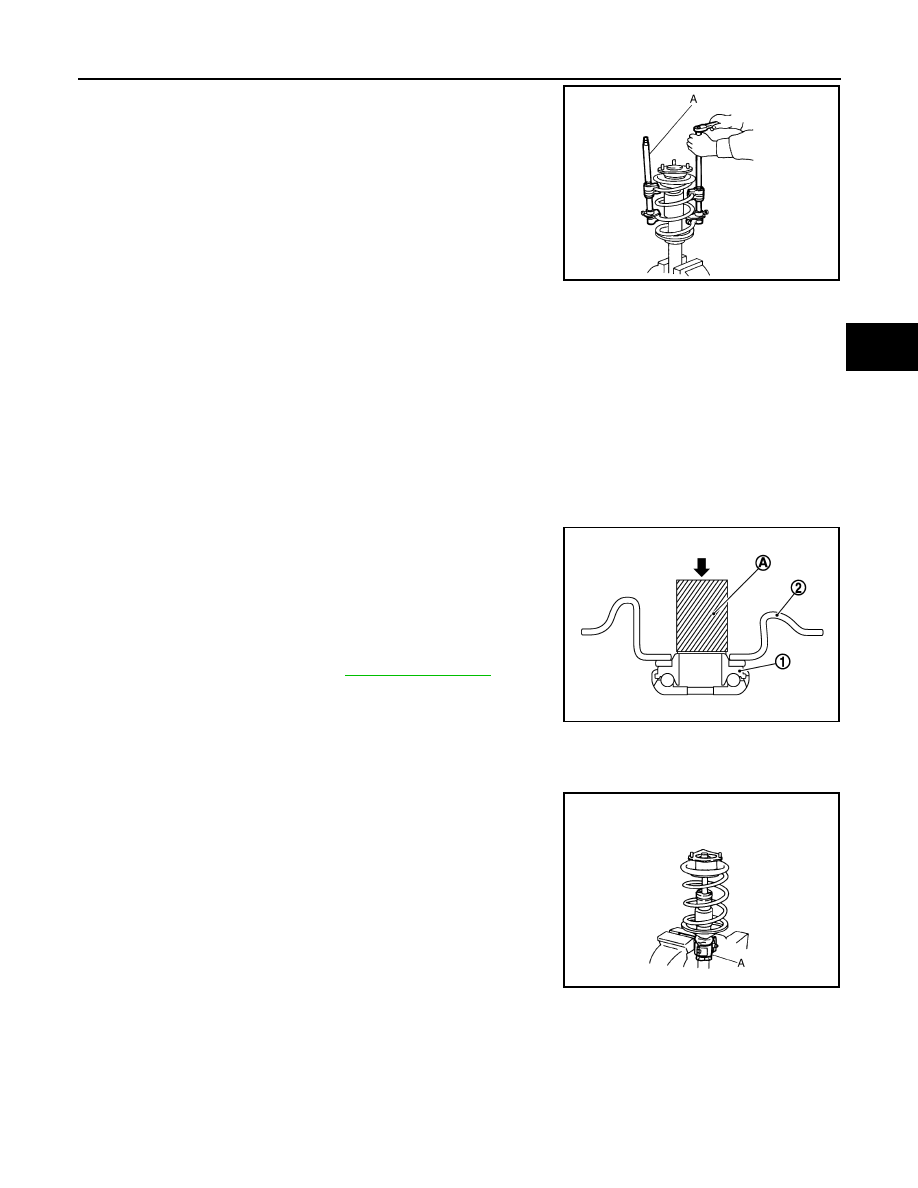

5. Compress coil spring using a suitable tool (A).

WARNING:

Make sure that the pawls of the suitable tool are firmly

hooked on the coil spring. The suitable tool must be tight-

ened alternately so as to not tilt the coil spring.

6. Make sure the coil spring is free between the spring upper seat and the strut.

7. Hold the piston rod and remove the piston rod lock nut.

8. Remove strut mount bearing, spring upper seat, and bound bumper as a set.

9. Remove bound bumper from spring upper seat.

10. Gradually release the suitable tool and remove the coil spring.

CAUTION:

Release the suitable tool while making sure the position of the suitable tool on the coil spring

does not move.

11. Remove the Tool from strut.

12. If necessary, remove strut mount bearing (1) from spring upper

seat (2), using a Tool (A).

CAUTION:

Do not disassemble the strut mount bearing unless damage

exists.

13. Inspect the components. Refer to

ASSEMBLY

CAUTION:

Do not damage the piston rod when removing components from the front coil spring and strut.

1. Install Tool (A) to the front coil spring and strut.

CAUTION:

When installing Tool (A), wrap a shop cloth around the front

coil spring and strut to protect the parts from damage.

2. Secure Tool (A) in a vise.

JPEIA0007ZZ

Tool number : ST35652000 ( — )

Tool number : KV10106700 ( — )

JPEIA0228ZZ

Tool number : ST35652000

JPEIA0006ZZ