Nissan Versa Note. Manual - part 392

EM-84

< REMOVAL AND INSTALLATION >

[HR16DE]

CYLINDER HEAD

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec-

ified level, if necessary.

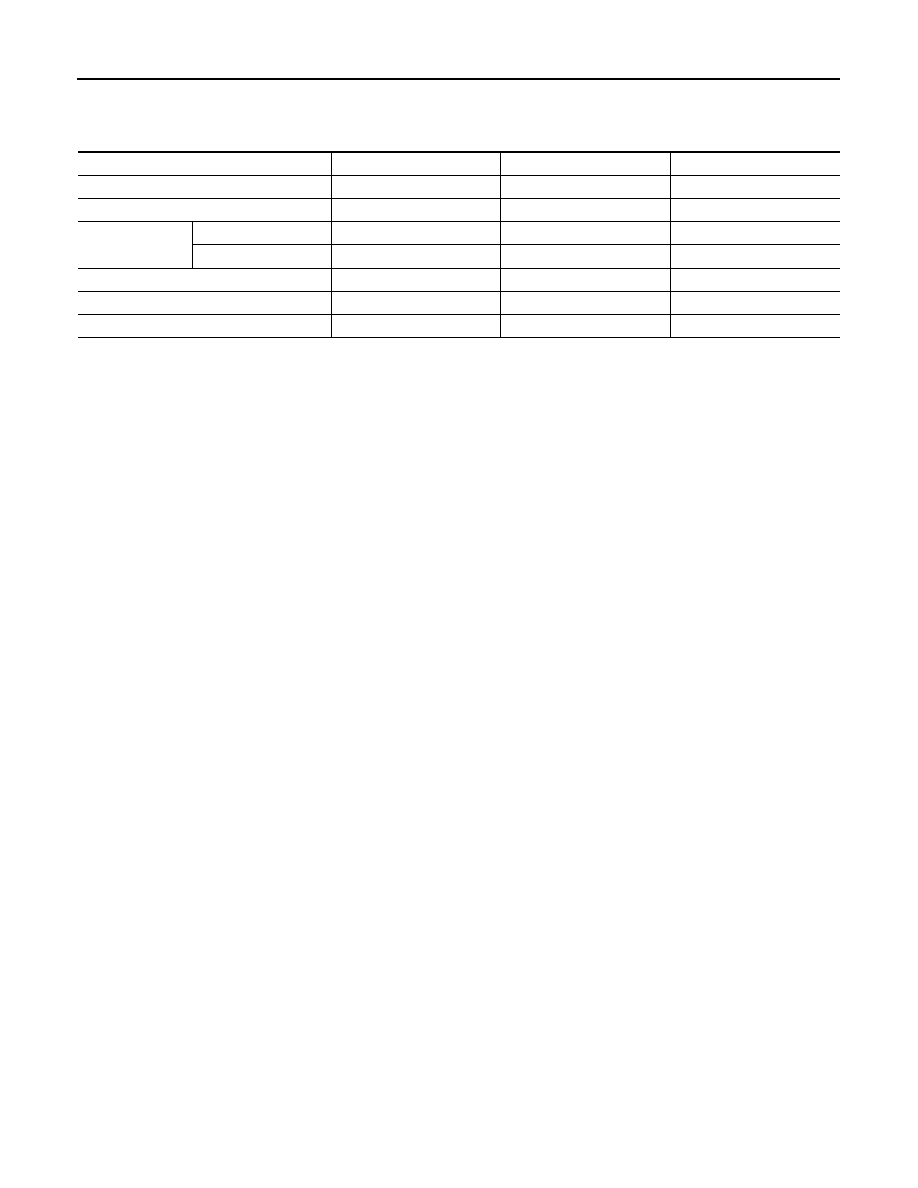

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc.

Item

Before starting engine

Engine running

After engine stopped

Engine coolant

Level

Leaks

Level

Engine oil

Level

Leaks

Level

Transmission/

transaxle fluid

CVT Models

Leaks

Level/Leaks

Leaks

M/T Models

Level/Leaks

Leaks

Level/Leaks

Other oils and fluids*

Level

Leaks

Level

Fuel

Leaks

Leaks

Leaks

Exhaust gas

—

Leaks

—