Nissan Versa Note. Manual - part 313

EC-234

< DTC/CIRCUIT DIAGNOSIS >

[HR16DE]

P0139 HO2S2

P0139 HO2S2

DTC Logic

INFOID:0000000009020743

DTC DETECTION LOGIC

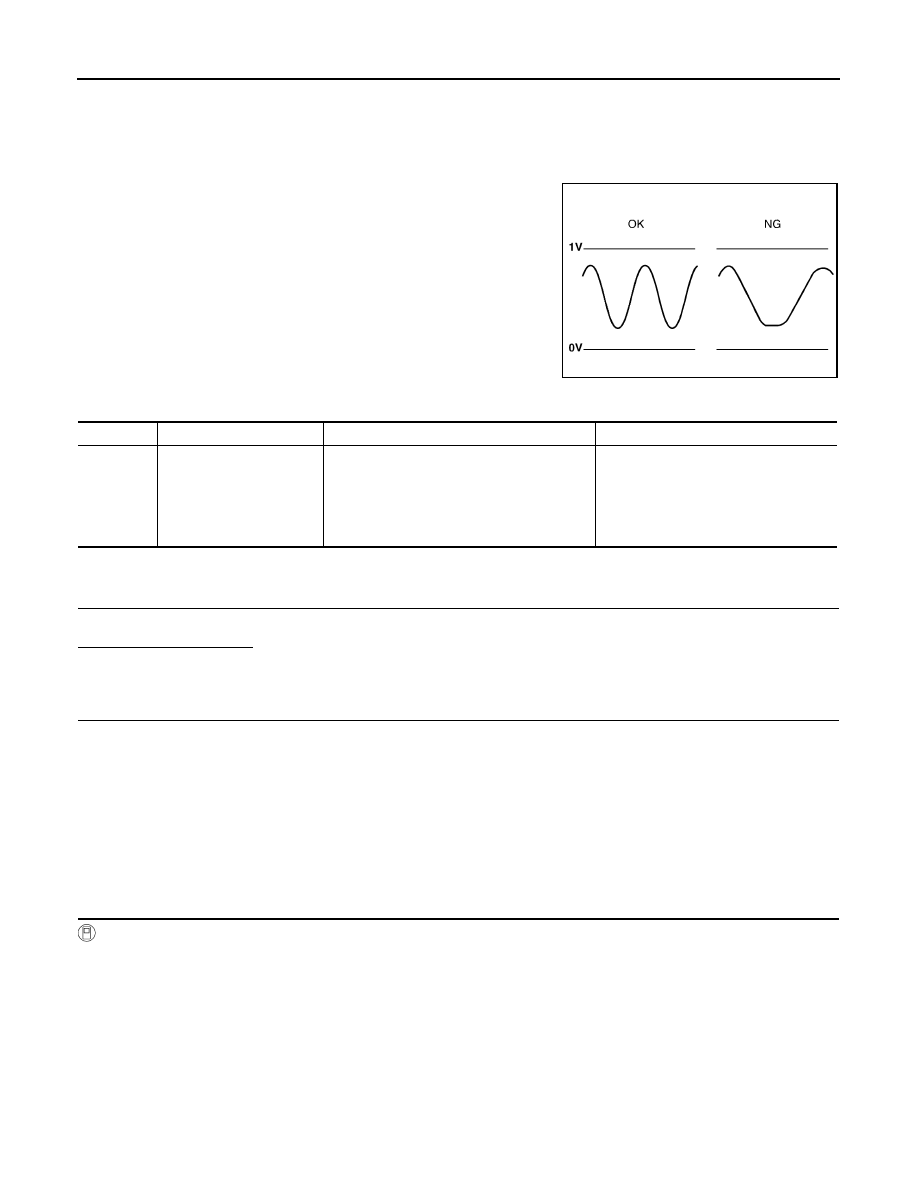

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the air fuel ratio (A/F) sensor 1. The oxy-

gen storage capacity of the three way catalyst (manifold) causes the

longer switching time. To judge the malfunctions of heated oxygen

sensor 2, ECM monitors whether the switching response of the sen-

sor's voltage is faster than specified during the various driving condi-

tion such as fuel cut.

DTC CONFIRMATION PROCEDURE

1.

INSPECTION START

Do you have CONSULT?

Do you have CONSULT?

YES

>> GO TO 2.

NO

>> GO TO 6.

2.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

For better results, perform “DTC WORK SUPPORT” at a temperature of 0 to 30

°C (32 to 86°F).

>> GO TO 3.

3.

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

6. Let engine idle for 1 minute.

7. Select “DATA MONITOR” mode of “ENGINE” using CONSULT.

8. Make sure that “COOLAN TEMP/S” indicates more than 70

°C (158°F).

If not, warm up engine and go to next step when “COOLAN TEMP/S” indication reaches to 70

°C (158°F).

9. Open engine hood.

10. Select “HO2S2 (B1) P0139” in “DTC WORK SUPPORT” mode of “ENGINE” using CONSULT.

SEF302U

DTC No.

Trouble diagnosis content

DTC detecting condition

Possible cause

P0139

Heated oxygen sensor 2

circuit slow response

It takes more time for the sensor to respond

between rich and lean than the specified time.

• Harness or connectors

(The sensor circuit is open or shorted)

• Heated oxygen sensor 2

• Fuel pressure

• Fuel injector

• Intake air leaks