Nissan Versa Sedan. Manual - part 837

TM-254

< SERVICE DATA AND SPECIFICATIONS (SDS)

[4AT: RE4F03C]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

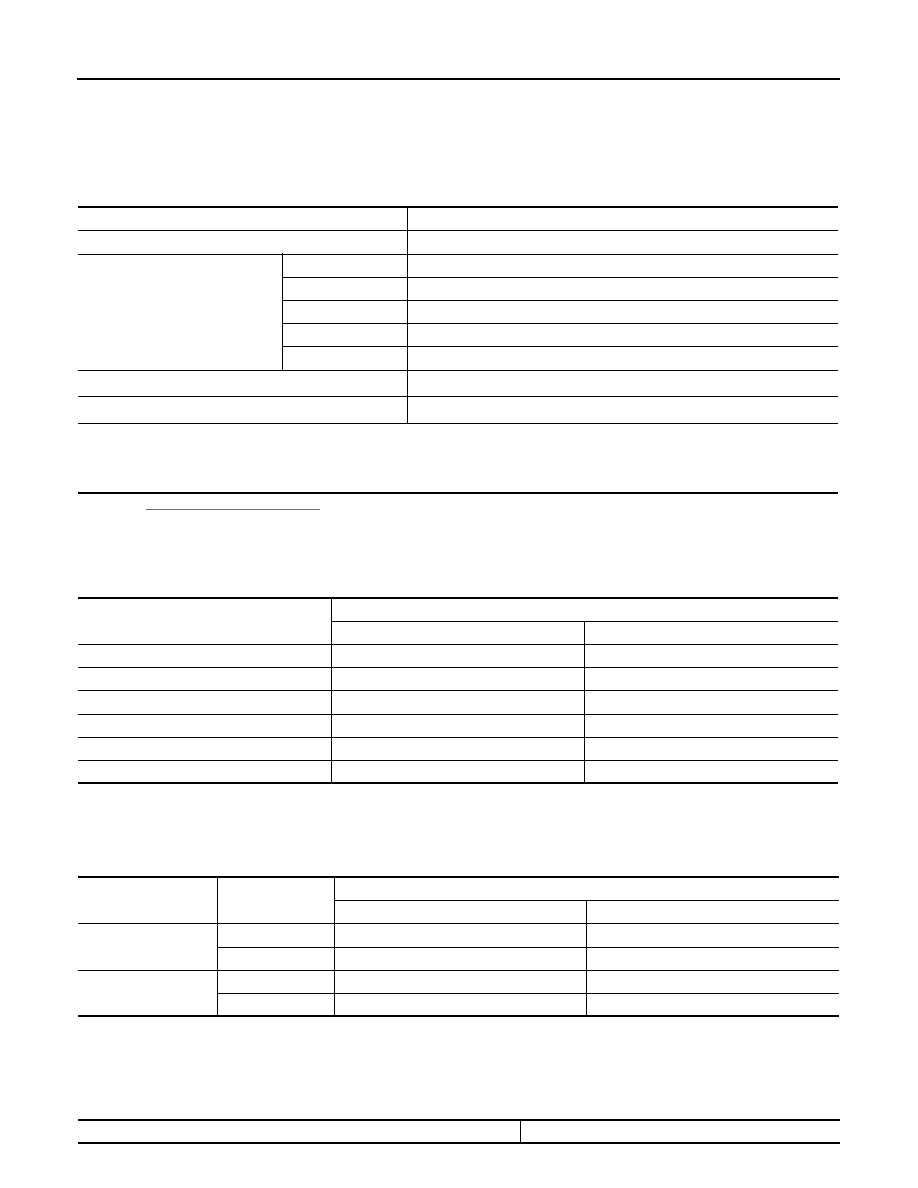

General Specification

INFOID:0000000009268043

*1: Refer to

MA-12, "Fluids and Lubricants"

.

*2: The fluid capacity is the reference value.

Vehicle Speed at Which Gear Shifting Occurs

INFOID:0000000009268044

Unit: km/h (MPH)

• At half throttle, the accelerator opening is 4/8 of the full opening.

Vehicle Speed at Which Lock-up Occurs/Releases

INFOID:0000000009268045

Unit: km/h (MPH)

• At closed throttle, the accelerator opening is less than 1/8 condition. (Closed throttle position signal OFF)

• At half throttle, the accelerator opening is 4/8 of the full opening.

Stall Speed

INFOID:0000000009268046

Transaxle model

RE4F03C

Stall torque ratio

1.91 : 1

Transmission gear ratio

1st

2.861

2nd

1.562

3rd

1.000

4th

0.697

Reverse

2.310

Recommended fluid

Genuine NISSAN Matic S ATF

*1

Fluid capacity

5.2 liter (5-1/2 US qt, 4-5/8 Imp qt)

*2

CAUTION:

• Use only Genuine NISSAN Matic S ATF. Do not mix with other ATF.

• Using ATF other than Genuine NISSAN Matic S ATF will cause deterioration of driveability and A/T durability, and may dam-

age the A/T, which is not covered by the warranty.

Gear position

Throttle position

Full throttle

Half throttle

D

1

→ D

2

52 – 58 (33 – 36)

28 – 34 (18 – 21)

D

2

→ D

3

98 – 104 (61 – 64)

56 – 62 (35 – 38)

D

3

→ D

4

155 – 161 (97 – 100)

122 – 128 (76 – 79)

D

4

→ D

3

150 – 156 (94 – 96)

63 – 69 (40 – 42)

D

3

→ D

2

88 – 94 (55 – 58)

39 – 45 (25 – 27)

D

2

→ D

1

38 – 44 (24 – 27)

17 – 23 (11 – 14)

Throttle position

Gear position

Vehicle speed

Lock-up ON

Lock-up OFF

Closed throttle

3GR

33 – 39 (21 – 24)

30 – 36 (19 – 22)

4GR

52 – 58 (33 – 36)

48 – 54 (30 – 33)

Half throttle

3GR (OD OFF)

87 – 93 (55 – 57)

84 – 90 (53 – 55)

4GR

122 – 128 (76 – 79)

92 – 98 (58 – 60)

Stall speed

2,410 – 2,850 rpm