Nissan Versa Sedan. Manual - part 480

REFRIGERANT

HA-19

< BASIC INSPECTION >

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

• Temperature setting: Full cold

• Fan speed: Maximum speed set

7. Run the engine at approximately 1,500 rpm for 2 minutes or more.

8. Stop the engine. Check again for refrigerant leakage. GO TO 4.

WARNING:

Be careful not to get burned when the engine is hot.

NOTE:

• Start refrigerant leak check immediately after the engine is

stopped.

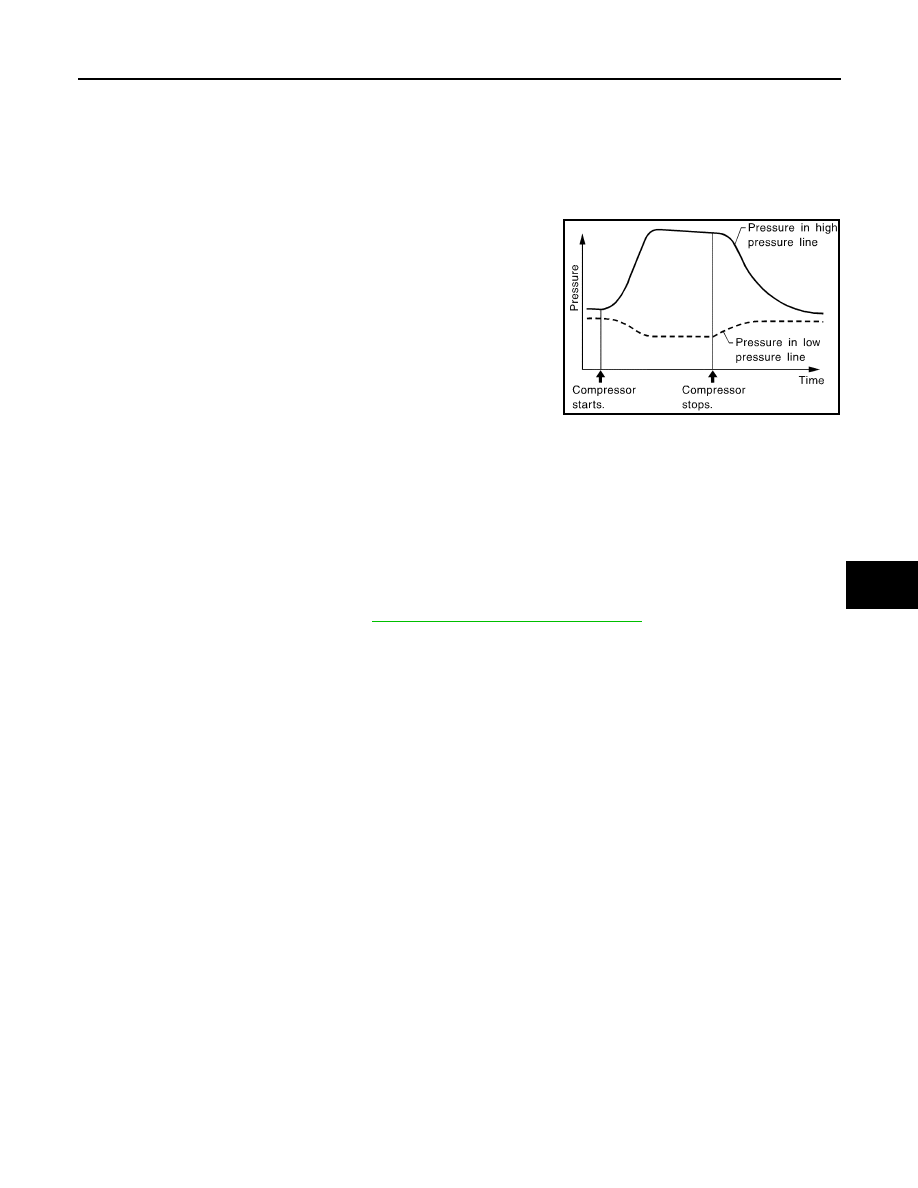

• When refrigerant circulation is stopped, pressure on the low-

pressure side rises gradually, and after this, pressure on the

high-pressure side falls gradually.

• The higher the pressure is, the easier it is to find the refriger-

ant leakage.

Recycle Refrigerant

INFOID:0000000009269739

WARNING:

• Always use HFC-134a for A/C refrigerant. If CFC-12 is accidentally charged, compressor will be dam-

aged due to insufficient lubrication.

• Always observe and follow precautions described on refrigerant container. Incorrect handling may

result in an explosion of refrigerant container, frostbite, or the loss of eyesight.

• Do not breathe A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose, or throat.

• Do not allow HFC-134a to be exposed to an open flame etc. because it generates poisonous gas

when in contact with high temperature objects. Keep workshop well ventilated.

1. Perform oil return operation. Refer to

HA-21, "Perform Oil Return Operation"

. (If refrigerant or oil leakage

is detected in a large amount, omit this step, and then GO TO 2.)

CAUTION:

Do not perform oil return operation if a large amount of refrigerant or oil leakage is detected.

2. Check gauge pressure readings of recovery/recycling/recharging equipment. When remaining pressure

exists, recycle refrigerant from high-pressure hose and low-pressure hose.

NOTE:

Follow manufacturer instructions for the handling or maintenance of the equipment. Do not fill the equip-

ment with non-specified refrigerant.

3. Remove A/C service valve cap from the vehicle.

4. Connect recovery/recycling/recharging equipment to A/C service valve.

5. Operate recovery/recycling/recharging equipment, and recycle refrigerant from the vehicle.

6. Evacuate air for 10 minutes or more to remove any remaining refrigerant mixed with compressor oil, etc.

7. Refrigerant recycle operation is complete.

Charge Refrigerant

INFOID:0000000009269740

WARNING:

• Always use HFC-134a for A/C refrigerant. If CFC-12 is accidentally charged, compressor will be dam-

aged due to insufficient lubrication.

• Always observe and follow precautions described on refrigerant container. Incorrect handling may

result in an explosion of refrigerant container, frostbite, or the loss of eyesight.

• Do not breathe A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose, or throat.

• Do not allow HFC-134a to be exposed to an open flame etc. because it generates poisonous gas

when in contact with high-temperature objects. Keep workshop well ventilated.

1. Connect recovery/recycling/recharging equipment to the A/C service valve.

2. Operate recovery/recycling/recharging equipment, and evacuate air from A/C system for 25 minutes or

more.

CAUTION:

SHA839E