Nissan Maxima. Manual - part 556

EM-112

< UNIT DISASSEMBLY AND ASSEMBLY >

CYLINDER BLOCK

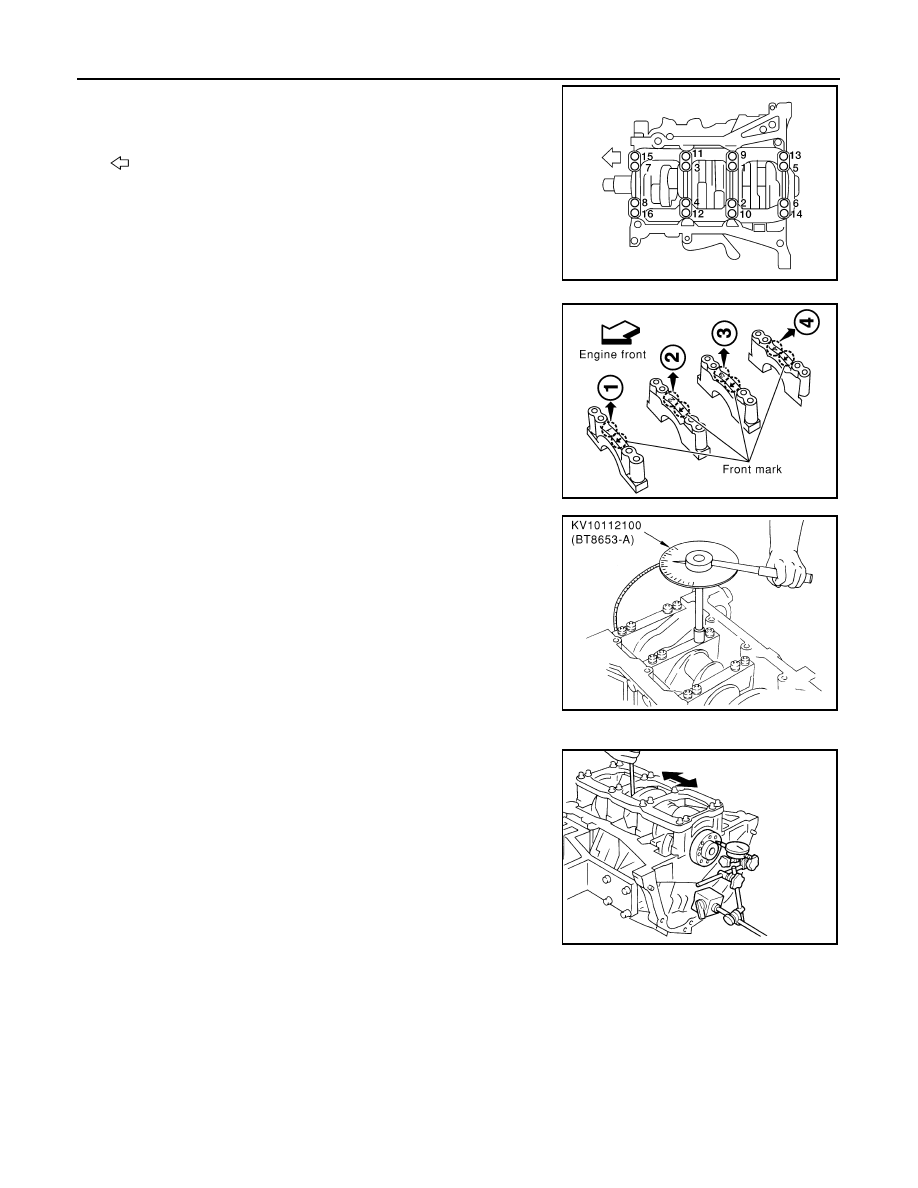

7. After installing the crankshaft, lower main bearings, main bear-

ing caps, main bearing beam, and bearing cap bolts. Tighten the

bearing cap bolts in the numerical order as shown.

a. Make sure that the front marks on the main bearing beam faces

the front of the engine.

b. Prior to tightening all the bearing cap bolts, place the bearing

beam in its proper position by shifting the crankshaft in the axial

position.

c.

After tightening the bearing cap bolts, make sure the crankshaft

turns smoothly.

d. Lubricate the threads and seat surfaces of the bolts with new

engine oil.

e. Tighten the bolts in two stages:

CAUTION:

Measure the tightening angle in two stages using Tool. Do not

measure with eyes only, be sure to use Tool.

8. Measure crankshaft end play.

• If beyond the limit, replace the bearing with a new one.

: Engine front

AWBIA1394ZZ

Stage 1

: 32.3 - 38.3 N·m (3.3 - 3.9 kg-m, 24 - 28 ft-lb)

Stage 2

: 90

° - 95° degrees clockwise

Tool number

: KV10112100 (BT-8653-A)

SEM456G

PBIC0096E

Standard

: 0.10 - 0.25 mm (0.0039 - 0.0098 in)

Limit

: 0.30 mm (0.0118 in)

SEM852E