Nissan Maxima. Manual - part 533

EM-20

< PERIODIC MAINTENANCE >

CAMSHAFT VALVE CLEARANCE

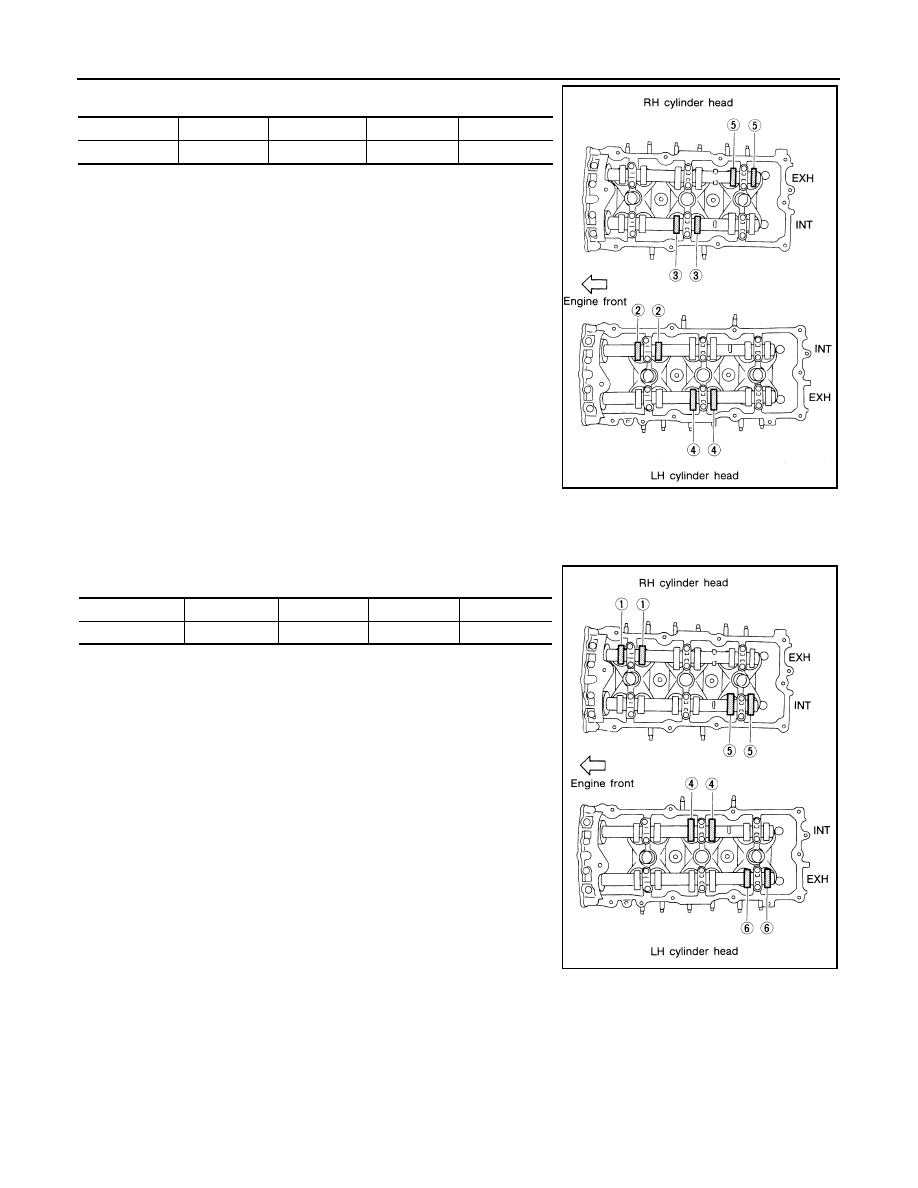

9. Check only those valve lifters as shown.

10. Turn the crankshaft 240

°.

11. Set No.5 cylinder at TDC on its compression stroke.

12. Check only those valve lifters as shown.

13. If all valve lifter clearances are within specification, install the following components. If the valve lifter

clearances are out of specification, adjust the valve lifter clearances.

• Intake manifold collectors

• Rocker covers

• All spark plugs

• All ignition coils

VALVE LIFTER ADJUSTING

Crank Position

Valve No. 2

Valve No. 3

Valve No. 4

Valve No. 5

No. 3 TDC

Intake

Intake

Exhaust

Exhaust

SEM894E

Crank Position

Valve No. 1

Valve No. 4

Valve No. 5

Valve No. 6

No. 5 TDC

Exhaust

Intake

Intake

Exhaust

SEM958E