Nissan Maxima. Manual - part 234

BR-4

< PRECAUTION >

PRECAUTIONS

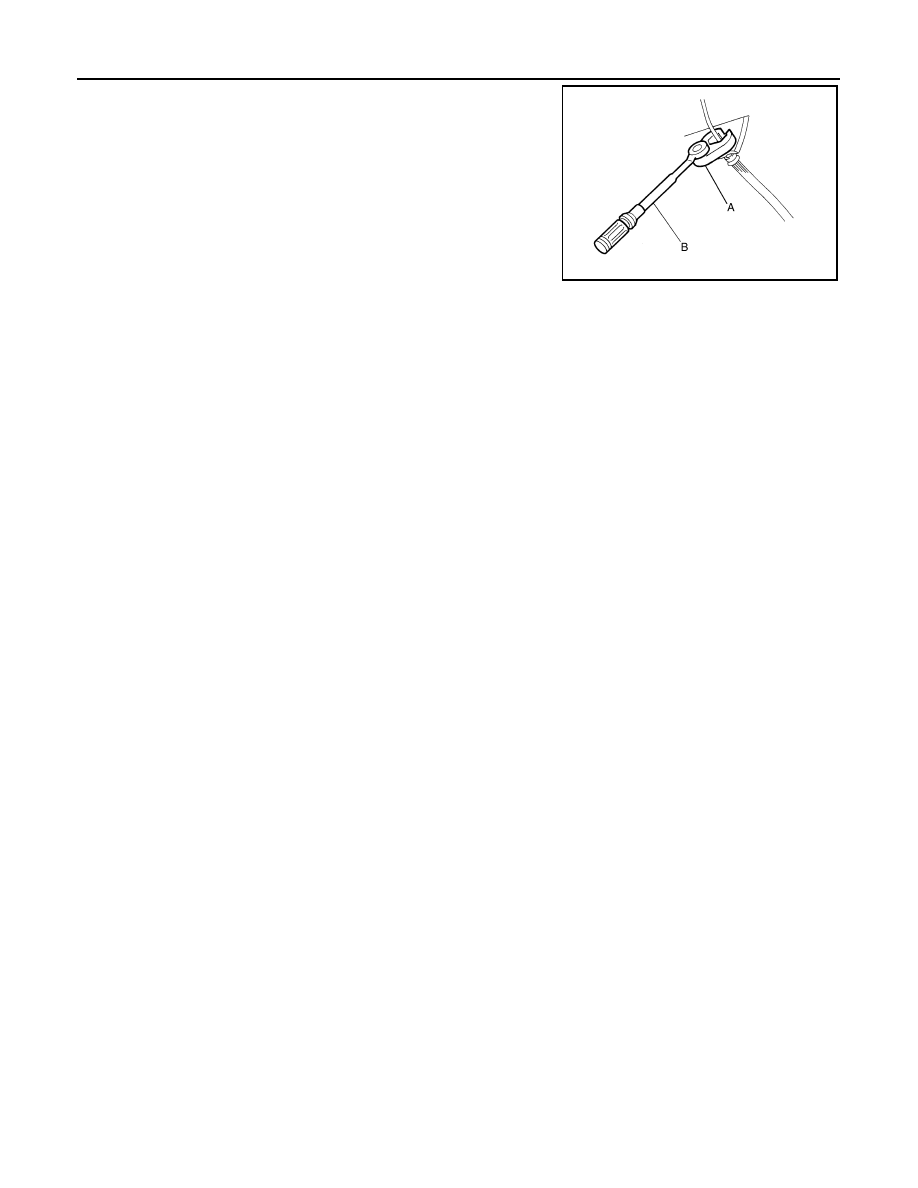

• Tighten the brake tube flare nut to the specified torque with a crow-

foot (A) and torque wrench (B).

• Always connect the battery terminal when moving the vehicle.

• Turn the ignition switch OFF and disconnect the ABS actuator and

electric unit (control unit) harness connector or the battery negative

terminal before performing the work.

• Check that no brake fluid leakage is present after replacing the

parts.

WARNING:

Clean brake pads and shoes with a waste cloth, then wipe with

a dust collector.

JPFIA0001ZZ