Nissan Altima HL32 Hybrid. Manual - part 349

EC-380

< COMPONENT DIAGNOSIS >

[QR25DE]

ASCD BRAKE SWITCH

• Junction block connector E46, E48

• 10A fuse (No. 3)

• Harness for open or short between ASCD brake switch and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors.

3.

CHECK ASCD BRAKE SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between ASCD brake switch harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> GO TO 4.

4.

DETECT MALFUNCTIONING PART

Check the following.

• Junction block connector E45, E46

• Harness for open or short between ASCD brake switch and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.

CHECK ASCD BRAKE SWITCH

EC-380, "Component Inspection (ASCD Brake Switch)"

.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Replace ASCD brake switch.

6.

CHECK INTERMITTENT INCIDENT

GI-42, "Intermittent Incident"

>> INSPECTION END

Component Inspection (ASCD Brake Switch)

INFOID:0000000004363302

1.

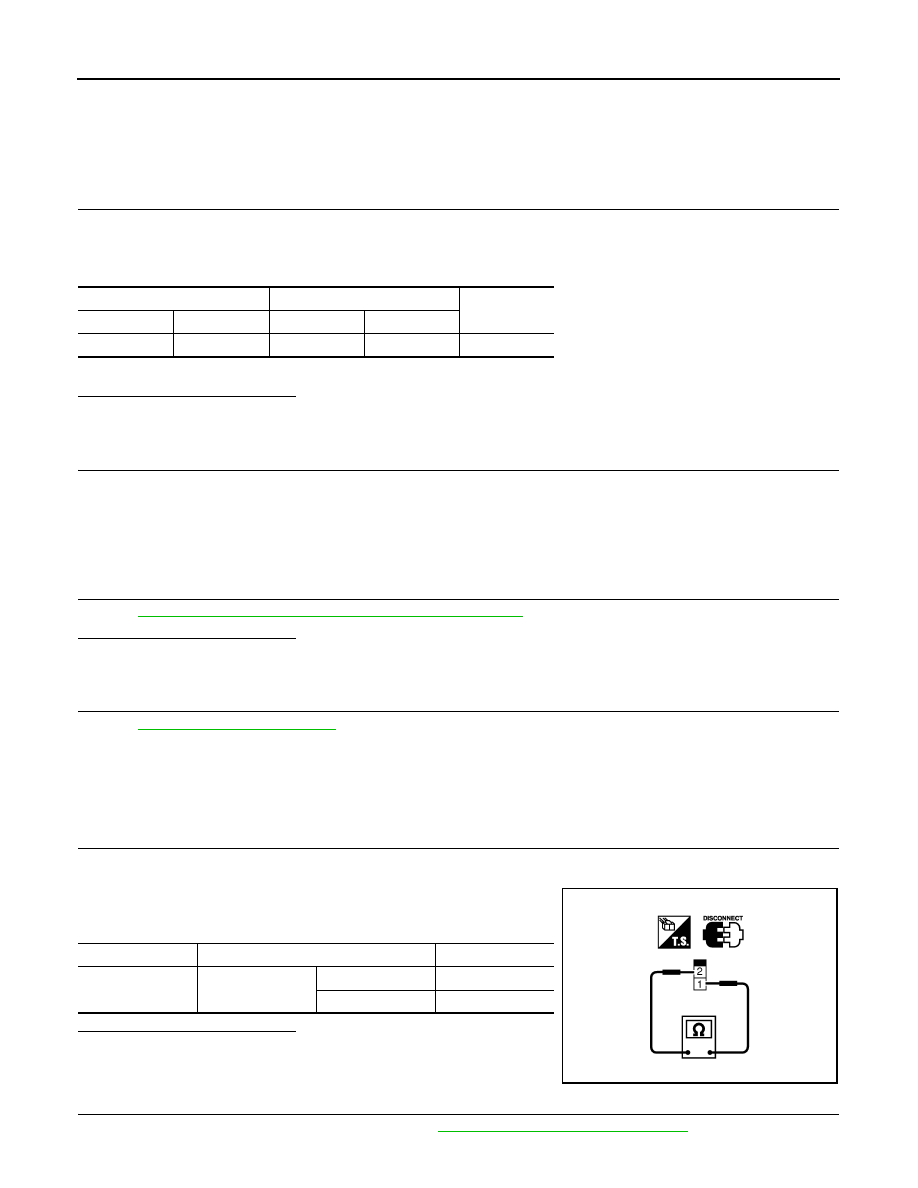

CHECK ASCD BRAKE SWITCH-I

1. Turn ignition switch OFF.

2. Disconnect ASCD brake switch harness connector.

3. Check the continuity between ASCD brake switch terminals

under the following conditions.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> GO TO 2.

2.

CHECK ASCD BRAKE SWITCH-II

1. Adjust ASCD brake switch installation. Refer to

BR-12, "Inspection and Adjustment"

ASCD brake switch

ECM

Continuity

Connector

Terminal

Connector

Terminal

E37

2

E10

110

Existed

Terminals

Condition

Continuity

1 and 2

Brake pedal

Fully released

Existed

Slightly depressed

Not existed

SEC023D