Nissan Altima HL32 Hybrid. Manual - part 136

C1290

BRC-109

< COMPONENT DIAGNOSIS >

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

C1290

Description

INFOID:0000000004212691

The brake ECU acquires steering angle sensor zero point every time the ignition switch is turned ON and the

vehicle is driven at 35 km/h (22 MPH) or more for approximately 5 seconds. The ECU also stores the previous

zero point.

If front wheel alignment or steering wheel position is adjusted without disconnecting the negative battery termi-

nal, or if yaw rate and acceleration sensor zero point is not acquired after the adjustments have been com-

pleted, the brake ECU detects the difference between the previous zero point and newly acquired zero point

and outputs this DTC to indicate a poor adjustment.

Warning of the steering angle sensor zero point malfunction will be cancelled by turning the ignition switch

OFF.

DTC Logic

INFOID:0000000004212692

Diagnosis Procedure

INFOID:0000000004212693

CAUTION:

When replacing the brake ECU, perform initialization of linear solenoid valve and calibration.

1.

PERFORM ZERO POINT CALIBRATION OF YAW RATE/SIDE/DECEL G SENSOR

Perform zero point calibration of the yaw rate/side/decel G sensor.

NOTE:

• When the stored zero point of the yaw rate/side/decel G sensor is erased, steering angle sensor zero point

will also be erased.

• If the zero point and output value of the yaw rate/side/decel G sensor and the output value of the wheel sen-

sors are not normal, steering angle sensor zero point cannot be acquired normally even if the vehicle is

driven straight ahead at 35 km/h (22 MPH) or more.

>> GO TO 2.

2.

CHECK STEERING ANGLE SENSOR ZERO POINT CALIBRATION

1. Drive the vehicle straight ahead at 35 km/h (22 MPH) or more for at least 5 seconds.

2. Check that the centered position of the steering wheel is correctly set, while driving straight ahead.

NOTE:

• If front wheel alignment and steering position are adjusted as a result of abnormal centered position of

the steering wheel, acquire yaw rate and acceleration sensor zero point again after the adjustments are

completed.

• The centered position of the steering wheel is correctly set.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Adjust front wheel alignment or steering position.

3.

RECONFIRM DTC

1. Turn the ignition switch OFF.

2. Clear the DTC.

3. Turn the ignition switch ON (READY).

4. Drive the vehicle and turn the steering wheel to the right and left at the speed of 35 km/h (22 MPH) or

more.

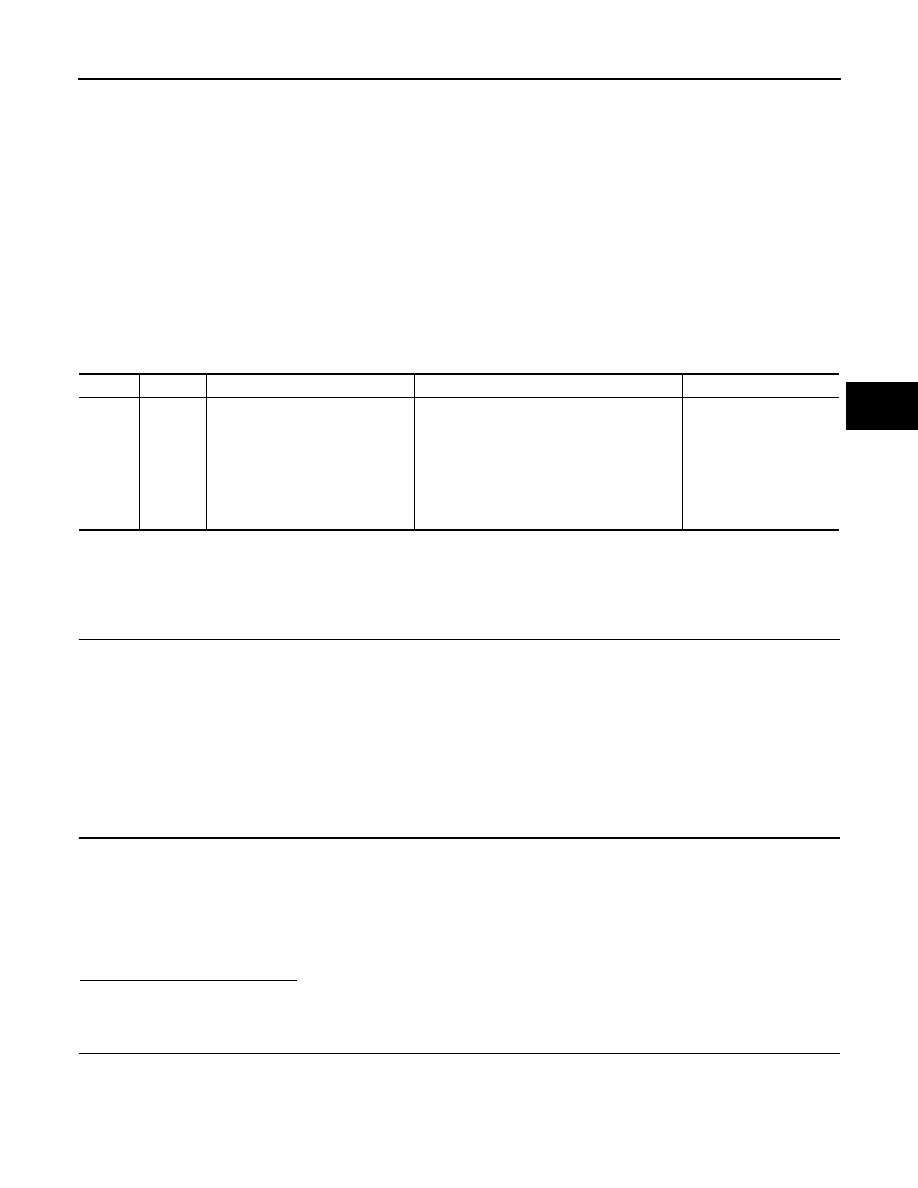

DTC

INF code

Display item

DTC detection condition

Trouble area

C1290

—

STR ANG SEN 0POINT

The steering angle sensor zero point calibra-

tion position vastly differs from the recorded

value.

• Yaw rate/side/decel G

sensor zero point cali-

bration incomplete

• Poor adjustment of the

centered position of the

steering wheel

• Poor adjustment of

front wheel alignment