Nissan PULSAR N13 Series / ASTRA LD Series. Manual - part 48

Electrical System

193

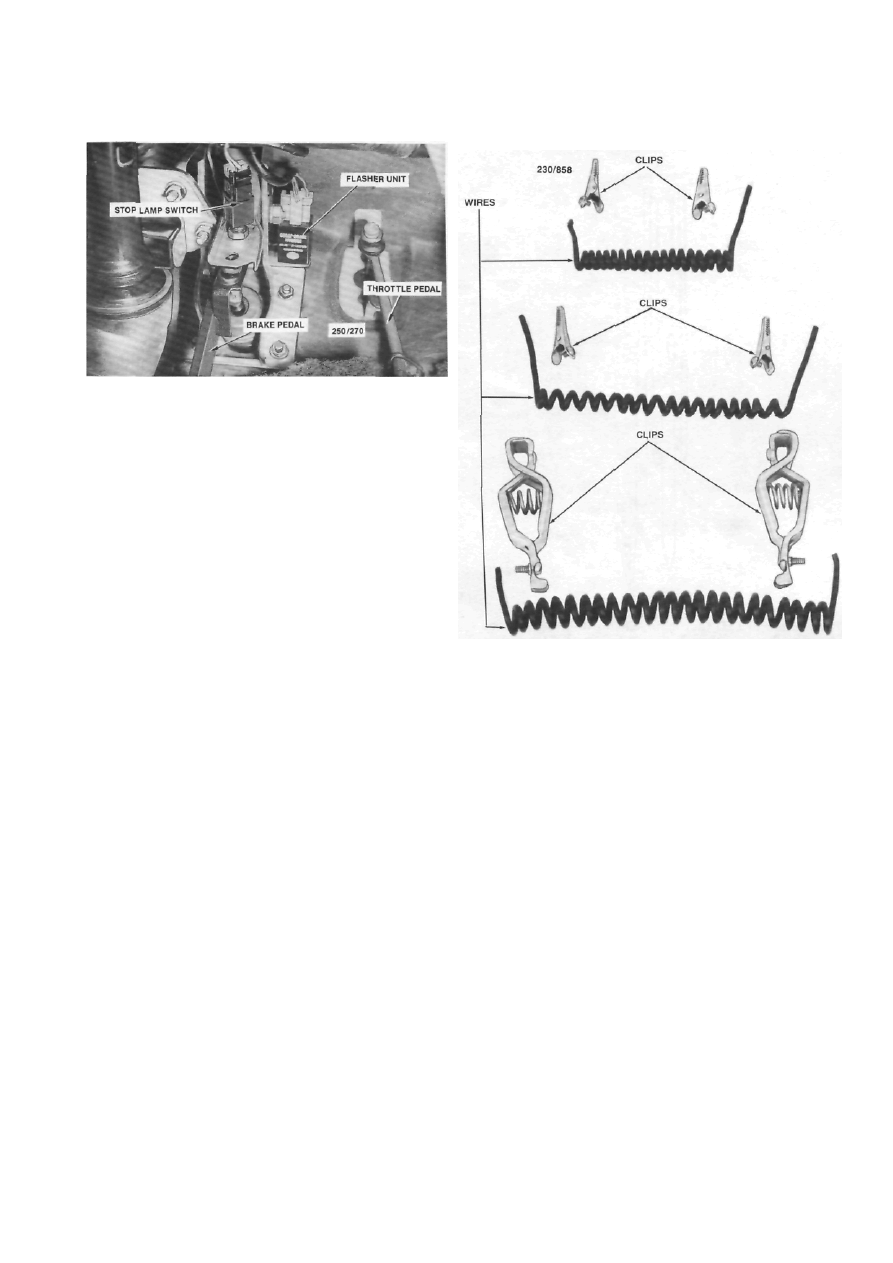

Installed view of the stop lamp switch and the flasher

unit.

(2) Fault in the warning lamp wiring: Check and

repair the fault.

NOTE: When renewing bulbs ensure that a

new bulb of the correct wattage is used.

TURN SIGNAL LAMPS FLASH WEAKLY AND

AT GREATER THAN NORMAL SPEED

1.

Faulty flasher unit: Check and renew the

flasher unit.

2.

Front or rear bulb blown on the turn side:

Check and renew the bulb.

NOTE: If the flasher unit is to be renewed,

always try to obtain a genuine replacement

part.

HAZARD WARNING LAMPS DO NOT

OPERATE

Fuse blown: Rectify the fault and renew as

necessary.

Flasher unit faulty: Renew the flasher unit.

Hazard warning switch faulty: Renew the

switch.

Fault in the wiring circuit: Check and repair

the fault.

5. TEST EQUIPMENT AND SOME

APPLICATIONS

Special Equipment Required:

To Make Test Lamp or Jumper Lead — Soldering

iron

When working on the electrical system, a test

lamp and jumper leads can be very useful to check

circuits.

TO MAKE A JUMPER LEAD

The minimum materials required to make a

jumper lead are one length of 4 mm wire and two

small alligator clips.

Grouping of materials to construct jumper leads of

various sizes.

Bare both ends of a suitable length of 4 mm

wire.

Connect a small alligator clip to each end of

the wire. Solder and tape the connections.

Test the jumper lead for continuity by re-

moving one battery cable and connecting the lead

between the cable and the battery terminal. Turn the

ignition On and the dashboard warning lamps should

operate indicating a completed circuit through the

jumper lead.

Remove the jumper lead from the circuit and

reconnect the battery.

NOTE: Make a few jumper leads of various

lengths using different sizes and types of

alligator and battery clips.

TO MAKE A TEST LAMP

Due to the extensive use of electronic components

in the electrical system, an LED (light emitting diode)

test lamp can be made from a suitable length of 3 mm

wire, an alligator clip, an LED, a 1/4 watt 560 ohm

resistor, a suitable case such as an old ball point pen

case and a length of rod or wire sharpened to form a

probe.

(1) Solder the length of wire to the K (cathode)