Nissan PULSAR N13 Series / ASTRA LD Series. Manual - part 39

Front Suspension

157

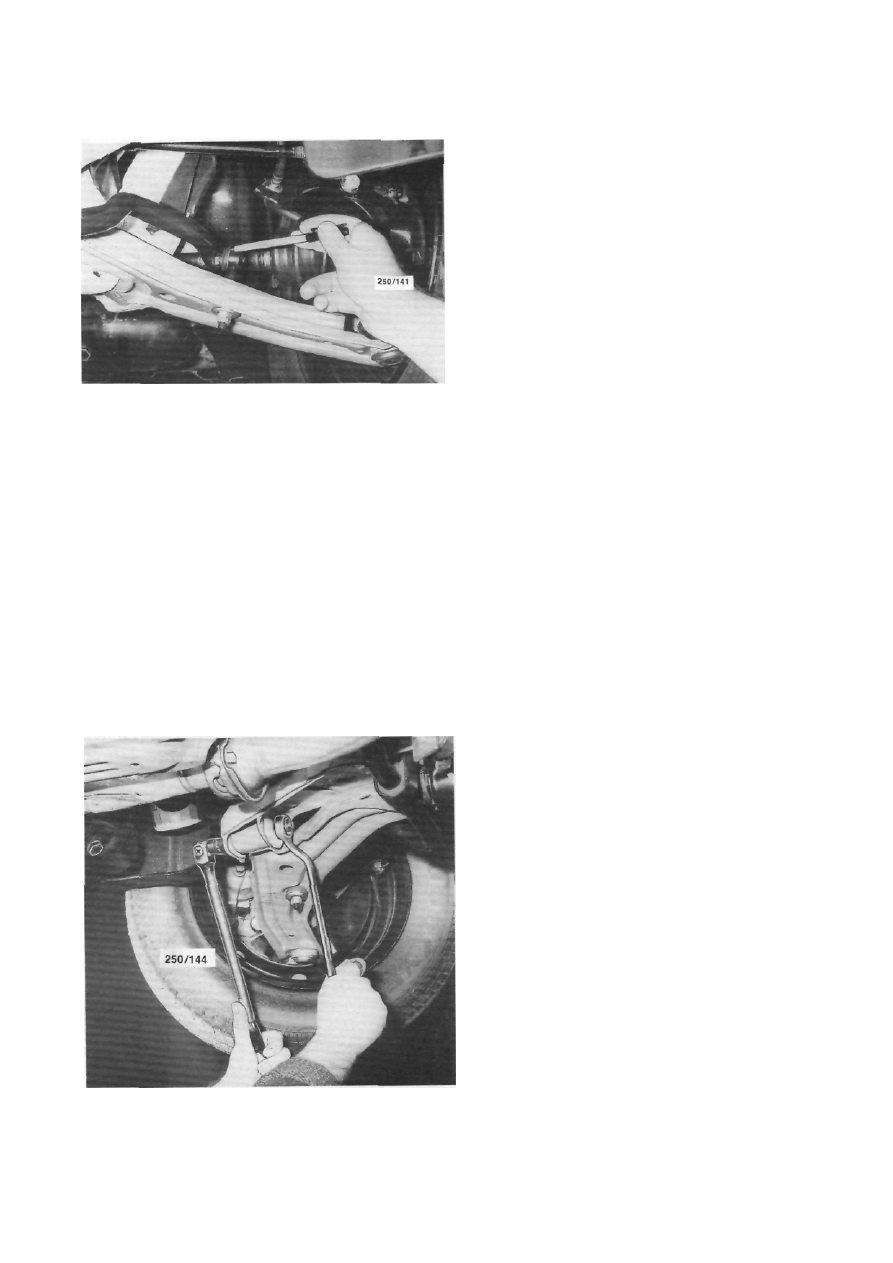

Check the stabilizer bar links for wear and damage.

(3) Incorrect front end alignment: Check and

adjust the alignment as necessary.

(4) Defective stabilizer bar mounting rubbers or

worn link ball joints: Renew component as necessary.

(5) Weak or broken front coil spring: Renew

both springs as a matching pair.

(6) Broken or weak rear coil spring: Renew both

springs as matching pair.

(7) Drive shaft bent or distorted: Check and

renew as necessary.

(8) Tie rod end worn or damaged: Check and

renew as necessary.

(9) Control arm ball joint worn or damaged:

Check and renew as necessary.

(10) Control arm mounting bolts loose: Tighten

the control arm bolts.

(11) Wheel hub bearing worn: Check and renew

as necessary.

NOTE: As a quick guide to suspension unit

condition, bounce the front of the vehicle up

and down (one side at a time), the vehicle

should come to rest in a single movement. If

it bounces two or three times before stop-

ping, the suspension unit should be renewed.

If the from of the vehicle is tower on one

side than the other, remove the coil spring

and check its free length against a new

spring. If the spring is found to be unservice-

able it is good practice to install two new

springs as a matching pair. This also applies

to the springs on the rear of the vehicle.

2. DESCRIPTION

The front suspension is an independent type

comprising two Macpherson strut suspension units

mounted vertically on each side of the vehicle. The

lower end of the suspension unit is bolted to the

steering knuckle, which in turn houses the front hub

bearings. The steering knuckle pivots on the control

arm by means of a ball joint.

The control arm pivots at its inner ends on rubber

bushes.

A stabilizer bar is attached to both ends of the

control arms using ball joint links. The stabilizer bar

is attached to the front underbody by brackets and

mounting rubbers.

Each front suspension unit assembly comprises a

tubular shock absorber type suspension unit, sur-

rounded at the upper end by a coil spring. On top of

the coil spring is the upper mounting which attaches

to the underside of the inner mudguard panel. The

piston rod of the suspension unit is attached to the

centre of the upper mounting by a rubber mounted

bearing.

When a suspension unit is found to be defective it

is recommended that both suspension units be re-

newed as a pair.

Camber is adjusted by means of a cam on the

upper steering knuckle to suspension unit mounting

bolt.

The kingpin inclination and caster are set in

production and cannot be adjusted. Any variation in

these angles will be caused by worn or damaged

components.

3. STEERING KNUCKLE

Special Equipment Required:

To Renew Wheel Bearing — Press and press plates

and suitable tubes and mandrels

To Check Hub End Float — Dial gauge

TO REMOVE AND INSTAL

( 1 ) Raise the front of the vehicle and support it

on chassis stands. Remove the front wheel.

Checking the control arm bolts for security.