Nissan PULSAR N13 Series / ASTRA LD Series. Manual - part 34

Manual Transaxle and Drive Shafts

137

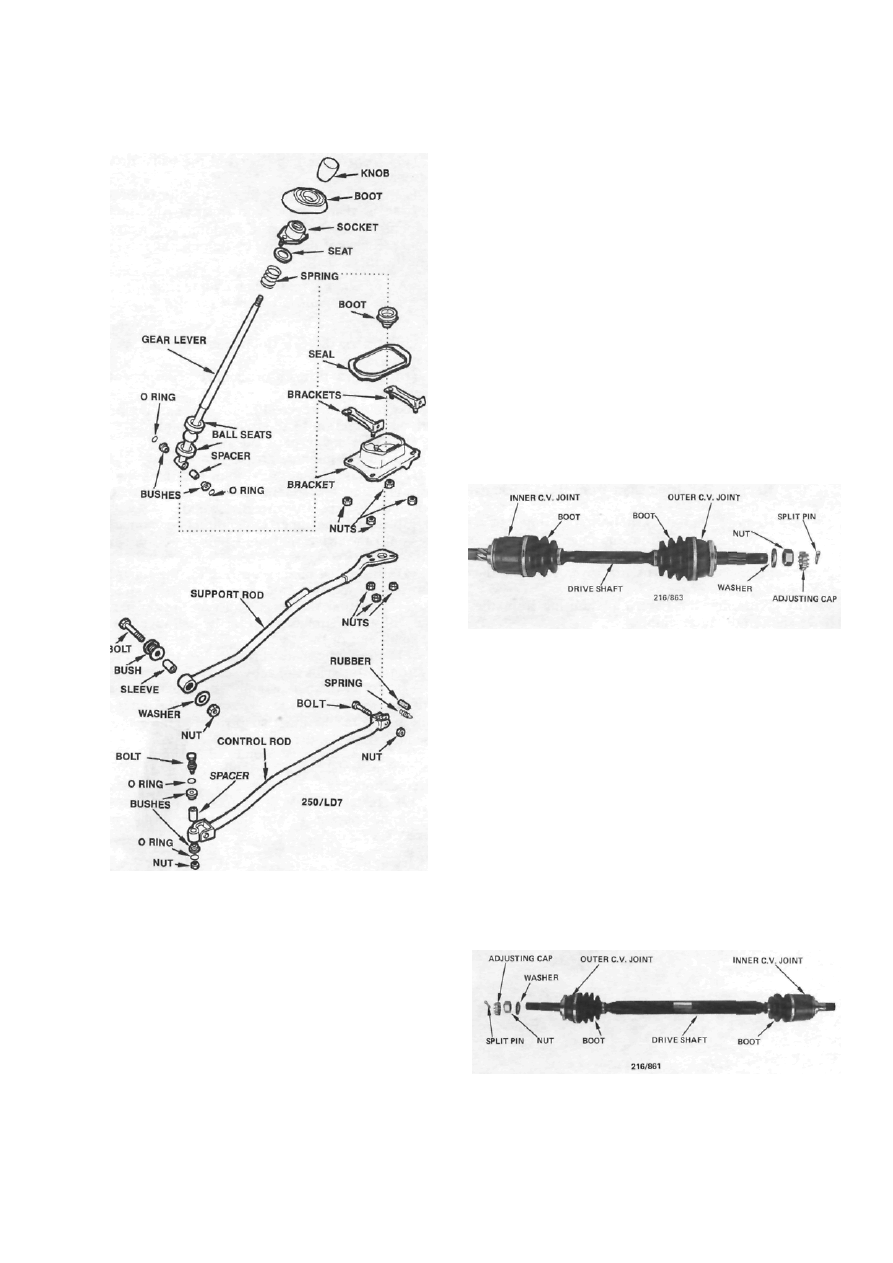

Dismantled view of the gear lever assembly.

(7) Remove the bushes, spacer and O rings from

the bottom of the gear lever.

(8) Remove the nuts retaining the floor bracket

to the vehicle floor panel and remove the bracket from

the vehicle.

(9) If necessary, disconnect the control rod and

the support rod from the transaxle and remove the

rods from the vehicle.

(10) Check all the components for deterioration,

wear and damage. Renew the unserviceable compo-

nents as necessary.

Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

(1) Install all the components to the locations

noted during dismantling.

(2) Lubricate all the pivot points with multipur-

pose grease prior to assembly.

(3) Tighten all the nuts securely.

(4) Road test the vehicle and check for correct

gear selection.

6. DRIVE SHAFTS

TO REMOVE AND INSTAL

(1) Remove the dust cap from the centre of the

front hub. Remove the split pin and nut retainer from

the outer end of the drive shaft.

(2) With an assistant applying the brakes, loosen

the nut on the outer end of the drive shaft.

(3) Raise the front of the vehicle and support it

on chassis stands. If necessary, refer to the Wheels and

Tires section for the correct jacking points.

Assembled view of the left hand side drive shaft

assembly.

(4) Remove the split pin and castellated nut

retaining the tie rod to the steering knuckle.

(5) Disconnect the tie rod end from the steering

knuckle using a suitable puller or alternatively place a

hammer or dolly on one side of the steering knuckle

and strike the opposite side with a hammer.

(6) Remove the split pin and castellated nut

retaining the suspension ball joint to the bottom of the

steering knuckle.

(7) Disconnect the suspension ball joint from

the steering knuckle using a suitable puller or alterna-

tively place a hammer or dolly on one side of the

steering knuckle and strike the opposite side with a

hammer.

(8) Remove the retaining bolts and remove the

brake caliper from the steering knuckle. Refer to the

Assembled view of the right hand side drive shaft

assembly.